Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The group of investigation of Processing and pyrolysis of polymers of the University of Alicante has developed a new combined filter that eliminates the tar, the nicotine and other toxic gases present in tobacco smoke in a very efficient way more efficiently than current filters available in the market. The invention is characterized because it combines three membranes of different characteristics arranged in a very specific way. The primary membrane (M1), located at the end closest to the tobacco column, is formed by a perforated disk of impermeable material. It also has an outer membrane (M3) of cellulose acetate fiber located at the end in contact with the mouth of the smoker. It can also incorporate a cylindrical intermediate membrane (M2) between M1 and M3 formed by an adsorbent material. This innovative combined filter has a low manufacturing cost, allows to dispense tastes and flavors, and can be applied in both commercial cigarettes and filters for rolling tobacco. Wanted companies interested in acquiring this technology for commercial exploitation.

Tobacco use represents a major public health problem worldwide. More than 6,000 compounds have been identified in tobacco smoke, of which approximately 100 are recognized as toxic or carcinogenic by the Food and Drug Administration (FDA).

The toxicity of tobacco smoke is recognized in all areas, and there is currently intensive research to reduce the toxic compounds inhaled by smokers.

Cigarettes are basically constituted by:

• A paper cylinder: its permeability affects has been widely studied and self-extinction papers have been developed.

• The tobacco mixture: genetic modifications have been made in the tobacco plant to reduce the emission of nicotine and tars; as well as the use of catalysts that reduce the emission of toxic products.

• The filter: different configurations have been used (multiple filters, concentric cylinders, helical grooves, etc.) in which active substances have been used (cellulose acetate, activated carbons, zeolites, mesoporous solids, polar chemical components, liquid fatty acids, matrices of thermostable synthetic resin, etc.) capable of reducing the inhalation of toxic substances by smokers.

The main problems of the current filters are:

a) Design technical difficulties.

b) High manufacturing costs.

This problem is still unresolved and new solutions must be developed.

A new combined filter has been developed that includes up to three different types of membranes, each with specific characteristics, where the location of these is essential to achieve a significant improvement in the elimination of tars and toxic compounds in tobacco smoke. It can be applicable to any type of commercial cigarette, and in the tubes to fill, as well as in filers for rolling tobacco.

This innovative combined filter comprises the following elements:

1. Primary membrane (M1): it is a semipermeable or impermeable membrane, circular or cylindrical in shape (with a diameter equal to that of the tobacco column or the conventional filter), which must be placed, immediately after the tobacco column and in contact with it. It can be made of different materials (for example: paper, cardboard, cardboard, wood, ceramics, metal, cellulose acetate, aluminum or other metal, plastic, foams of closed pore plastic materials, etc.), as long as these are not toxic, and includes a certain number holes of small size that cross it perpendicular to the circular section. By regulating the number of holes and their diameter, it is possible to control the reduction the inhalation of tar, nicotine and other harmful substances present in tobacco smoke. This membrane may include a layer of adhesive or self-adhesive to facilitate the consumer's incorporation, especially in its direct application to the conventional filter in rolling tobacco. This membrane could be separately commercialized for this application.

To avoid excessive draw resistance in the smoking process, the balance between the number of holes and its diameter is crucial.

This membrane is capable of incorporating tastes or flavors (for example: menthol, cocoa, vanilla, etc.), or any other additive, so that the smoke, when passing through the orifices, entrains these substances transmitting them to the smoker.

2. Intermediate membrane (M2): it is located between the primary membrane (M1) and the outer membrane (M3). It has a cylindrical shape and is formed by an adsorbent material composed of mesoporous silica type solids (for example, SBA-15), silicates and aluminosilicates (for example, MCM-41), zeolites or mesoporous activated carbons, all of them with a suitable granulometry. These materials can be included or not, in a permeable matrix of plastic material or fibers (for example, cellulose acetate or cotton). This membrane can incorporate aluminum or other active metals in its structure. M2 acts on the gases generated by adsorbing certain harmful compounds, which significantly reduces its inhalation by the smoker.

The effect of this membrane is complementary to that of the primary membrane (M1), since it can act on certain compounds such as carbon monoxide, methane, ethane, ethylene, isoprene, benzene, toluene, crotonaldehyde, or other lighter that do not condense in M1.

This type of membrane also allows the incorporation of tastes or flavors, being more effective for this purpose than the primary membrane.

3. External membrane (M3): this membrane is in contact with the smoker's mouth (it is the classic filter). It is cylindrical and consists of cellulose acetate fiber. It can incorporate ducts of different sections, and it is likely to include capsules of flavors, flavors and other substances, either adsorbed or as a physical mixture, so that they are released in the mainstream to be traversed by tobacco smoke.

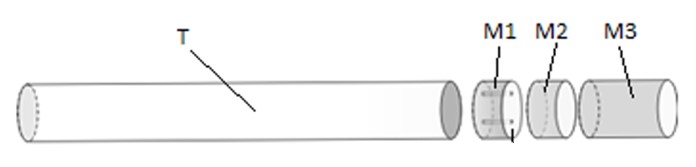

Figure 1: tobacco column (T) and combined filter formed by: the primary membrane (M1), the intermediate membrane (M2) and the outer membrane (M3).

Next, some of the realizations that have been carried out in the experiments are described:

First implementation: The combination of M1 (with 2 holes) + M3 has been tested, and an important tar condensation has been observed immediately after the M1 holes. It has also been observed that the end of M3 (in contact with the mouth of the smoker), is considerably less dirty than when M1 is dispensed with.

With this combination of membranes (M1 + M3), the reduction of light gases (carbon monoxide, methane, ethane, ethylene, isoprene, benzene, toluene and crotonaldehyde) is less than 15%, however, it is possible to reduce more than 60% of the nicotine and tar that the smoker would inhale compared to commercial filters.

The number of puffs is similar to that of conventional cigarettes, so the loss of pressure is not a significant factor. In addition, it has been tested by voluntary smokers, and it has become clear that its smoking characteristics are analogous.

Second implementation: As the number of holes in M1 increased, voluntary smokers showed a greater resistance to smoking (the number of puffs increased remarkably), however, a 75% reduction in the content of harmful substances was observed (tar and nicotine).

By varying the diameter of the holes, it was concluded that the result was dependent on the free passage through the holes.

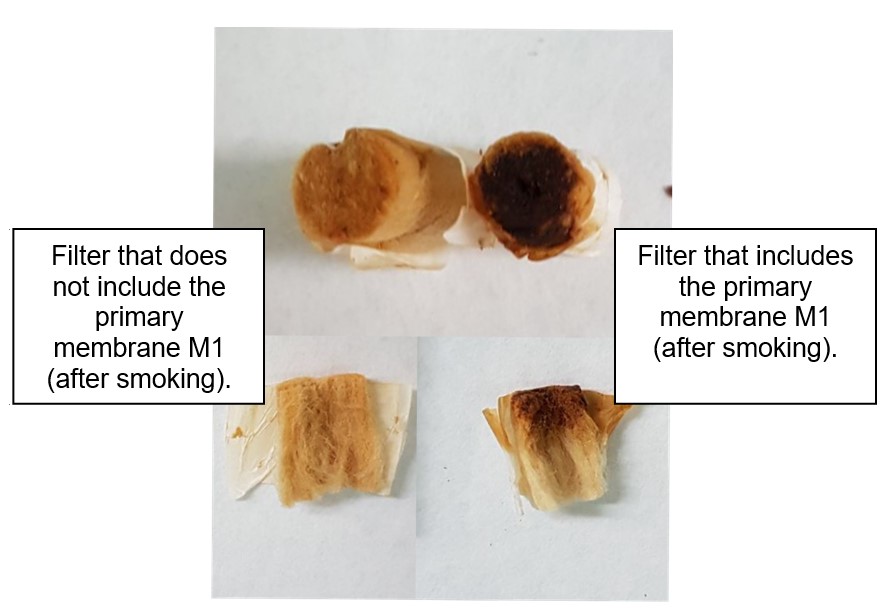

Therefore, this device is highly effective in reducing tar and nicotine from tobacco smoke. In fact, this effect is easily noticeable by the smoker, since the end of the filter that is in contact with his mouth is much cleaner after the smoking process than in commercial filters (see Figure 2).

In addition, by adjusting both the number of holes and their diameter, the pressure loss can be regulated so that it does not make a big difference with respect to conventional filters.

Third implementation: The thickness of the outer membrane (M3) has been varied, and it has been found that its length is independent of the result, since M1 is much more effective than M3, so a small thickness in M3 is enough to achieve very satisfactory results. At the same time, it means save manufacturing costs.

Fourth implementation: Both the thickness and the type of material have been varied in M1, and it has been concluded that both factors have a very reduced effect on their behavior, so that very economical and thin materials can be used to reduce costs of manufacture.

Fifth implementation: An intermediate membrane (M2) was introduced between M1 and M3 which contained an adsorbent material. With M2 it has been possible to reduce the inhalation of tar and nicotine by smokers by more than 70%, and what is more important, a reduction in the carbon monoxide inhalation has been achieved by more than 40%. In the case of other components of the smoke stream (methane, ethane, ethylene, isoprene, benzene, toluene and crotonaldehyde), significant reductions of between 30% -60% have been achieved.

Regarding the degree of compaction of the M2 membrane, an increase in density increases its effectiveness, although it has an undesired effect on smoking resistance. Therefore, parameters such as the ratio of adsorbent/fiber, the thickness and the way of preparation of this membrane can considerably affect the results obtained.

Sixth implementation: In any of the membranes (M1, M2 and M3), tastes and flavors can be incorporated very effectively, giving totally similar results to their commercial counterparts.

This new combination of membranes provides the following advantages over the systems currently available in the market:

1) Drastically reduces the inhalation of toxic compounds by the smoker.

Examples of reduction percentages for some substances, among many others:

2) Greater effectiveness than current filters.

3) Low manufacturing cost: less material is required to achieve greater filtering effectiveness.

4) Wide profit margin for the company.

5) It allows dispensing different tastes or flavors to the smoker.

6) Draw resistance is maintained during smoking.

7) It can be adapted in a simple way to any type of cigarette: both commercial (cigarettes, cigars, cigarillos, unfiltered cigarettes), and in rolling tobacco.

8) Versatility of commercialization: the membranes can be manufactured separately and used directly by the consumer in rolling tobacco cigarettes, or already assembled in commercial filters.

9) It is a solution much in demand by smokers.

A new type of filter has been developed that includes up to three membranes, each of them with specific characteristics, where the location of these is essential to achieve the objective of improvement in the results of removal of tar, nicotine and toxic compounds of smoke of tobacco, may be applicable to any type of cigarette.

In this sense, the primary membrane (M1) is located next to the tobacco column and in contact with it. This perforated membrane causes an acceleration and post-orifice expansion in the smoke column, which leads to a condensation of the toxic compounds, thus preventing them from coming into contact with the mouth of the smoker.

The positive visual effect for the smoker is very evident, since he can easily verify that the end of the filter in contact with his mouth (M3), is clearly cleaner than with a conventional filter.

Figure 2: it shows the aspect of a filter after smoking the same tobacco, under the same conditions, not using the membrane M1 (left part of the pictures) as compared to a filter using the M1 membrane (right part of the pictures). It can be observed the high amount of tars condensed in the second case, as well as that the end of the filter in contact with the mouth of the smoker is clearly cleaner in the second case. This fact clearly shows the lower amount of tar inhaled by the smoker if using this innovative filter.

The proposed location of the membranes must be respected, because a change in them, for example, exchanging M1 with M3, it would cause condensation of the tar in the mouth, generating a very unpleasant sensation for the smoker. In addition, this action can increase the adverse effects for the oral health of the smoker, as well as the adverse aesthetic effect of tar stains on the filter.

Therefore, it is the joint use of the membranes in the proper order, which allows obtaining the favorable results.

This innovative filter has been tested successfully both at the laboratory level and by voluntary smokers. For this, prototypes have been developed.

The smoking experiments in the laboratory were carried out with 3R4F tobacco from the University of Kentucky following the conditioning and smoking conditions described in ISO 3308.

A smoking machine under standard conditions has been used, and both the composition of the gases obtained and the condensed matter in Cambridge glass fiber filters located after the filters developed in the present invention have been analyzed. The non-condensable products were collected in a Tedlar bag for gases located behind the Cambridge filter, and analyzed by gas chromatography.

The present invention is part of the tobacco industry, referred to cigarettes, and in particular, a combined filter for use in any type of tobacco column, both in the variety of commercial cigarettes, cigars, cigarillos, unfiltered cigarettes, stuffed tubes and hand-rolled cigars.

Therefore, according to its final use, the filter can present different variants.

Companies interested in acquiring this invention for commercial exploitation are looked for:

• Patent licensing agreements.

• Development of new applications.

• Agreements regarding technology and knowledge transfer.

Company profile sought:

1) Manufacturers of complete nozzles.

2) Membrane manufacturers for filters.

3) Manufacturers of tobacco and cigarettes.

4) Smoking paper manufacturers.

5) Smoking filter manufactures.

The present invention is protected by patent application:

• Title of the patent: “Filtro combinado para la eliminación de alquitranes y compuestos tóxicos del humo del tabaco”.

• Application number: P201731446.

• Application date: 21st of December, 2017.

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959