Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Colour and Vision Research Group of the University of Alicante has been designed a new process to develop nano-structured hybrid nanopigments (from synthetic or natural dyes). These nanopigments confer improved optical, thermal, and mechanical properties when they were applied on composite materials. The nanoclays, dyes, and additives have been selected depending on the composite matrix source. Also, it has been selected the additives order in the process of synthesis, based on the material properties that would be going to improve.

The parameters that could be control with this new system are: the adsorbed dye concentration, the degradation temperature of the reinforced dye, the degradation temperature of the final nanocomposite, the bending resistant modulus, and the UV-VIS colour fastness. Also, it can be controlled the optical properties as transparency and colouring power degree. It is looking for companies interested in commercial exploitation of these new colored nanomaterials.

The composites development using nanometric scale additives (as nanoclays) allows the high performance materials for different industrial sectors. The nanoclays reinforce and improve the mechanical properties of the polymer matrix, depending on their compatibility and exfoliation capacity on the selected polymer. The final properties of the composites will depend on the exfoliated percentage of the nanoclays, or the aggregation formation on the matrix polymer.

The best properties will be achieved whit the exfoliated composites, instead of the intercalated ones. For that performance, it is often necessary to modify the nanoclays properties surface, using additives, to achieve the correct polarity and to get an uniform dispersion of the particles (Figure 1).

In the last few years, the conventional polymer matrix has been substituted by polymers from biomass, or biopolymers. The aim is to improve the thermal, mechanical and barrier properties of the biopolymer to enable its use on different industrial applications, using environmental friendly materials at the same time.

The research group applied the nanoclays (that previously were exchanged with dye molecules), obtaining the hybrid pigments, or nanopigments. Then, it was used the nanopigments as additives on composite materials. With this technique, it will be improved at the same time the mechanical, thermal, barrier properties and the optical polymer properties. It will be guaranteed the colour fastness properties when it was achieved the nanopigment particles exfoliation on the different polymer matrix. Almost it will be avoided the dye migration problems though the polymer matrix to the polymer surface.

Depending on the material properties that would be improved, the nanoclay structures, the surface additives/modifiers, and their incorporation moment during the synthesis process are selected.

The nanopigment synthesis process, with selected optical and thermal properties, needs the inorganic component (nanoclay) modification, in order to allow and improve the dye interaction, and then, the polymer matrix interactions. It has been selected these modifier classes:

1. Surfactants: ionic, cationic, non-ionic or amphoteric.

2. Mordants: tannic acid, alum, urea, chrome alum, metallic salts or bio-mordants.

3. Coupling agents: silane or silsesquioxane.

For the nanopigment synthesis and the nanocomposite generation, the following components have been selected:

1. Nanoclays: the inorganic host has a mixed morphology, lamellar and/or fibrillary, as nanotubes and channel types as zeolites, and a mixed scale size. It can be anionic or cationic exchange capacity nanoclays.

2. Dyes: they are from natural or synthetic sources, with different structures: azoic, metal complex, nitrous, nitro, arithmetic, methyl, iminoquinone, sulfur, anthraquinone, indigoid and phthalocyanine.

3. Thermostable polymers (resins) from different sources (natural, synthetic and blends), with the corresponding curing agents, and if it is necessary, selected compatibilizer additives as surfactants, coupling agents, etc.

4. Thermoplastic polymers from different sources (natural, synthetic and blends), and if it is necessary, selected compatibilizer additives as surfactants, coupling agents, etc.

It has provided added valued to the selected dyes, with this new procedure, improving the following properties:

• It maximizes the adsorbed dye in the nanoclay.

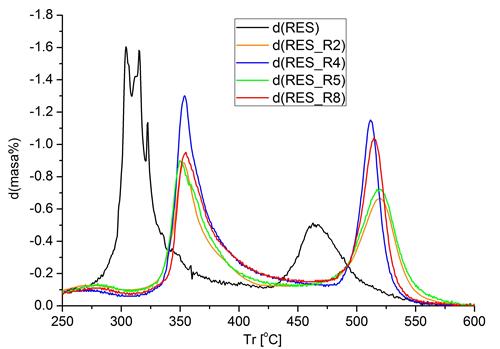

• It maximizes the dye temperature fastness (degradation temperature).

• It maximizes the polymer matrix temperature resistance (degradation temperature).

• It improves the mechanical polymer matrix properties, as flexural / tensile resistance, and also it changes the viscosity of the initial matrix.

• It improves the oxygen and water barrier properties of the polymer matrix.

• It improves the polymer flame retardant properties.

• It improves the colored biopolymer transparency properties.

• It maximizes the nanopigments coloring power, applied on a polymer matrix.

• It maximizes the UV-Vis colour fastness using nanoclays as host in the hybrid pigments.

• It minimizes or avoids the dye migration effects on their application, both wet or dry conditions.

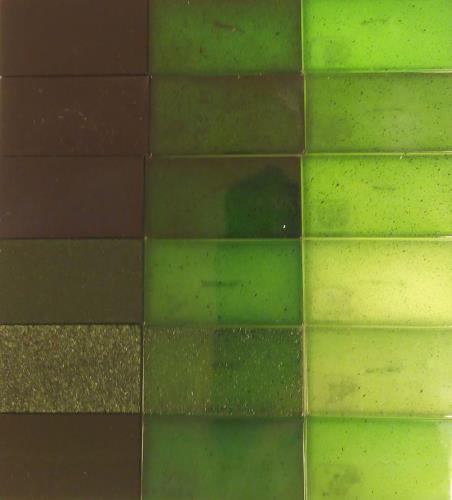

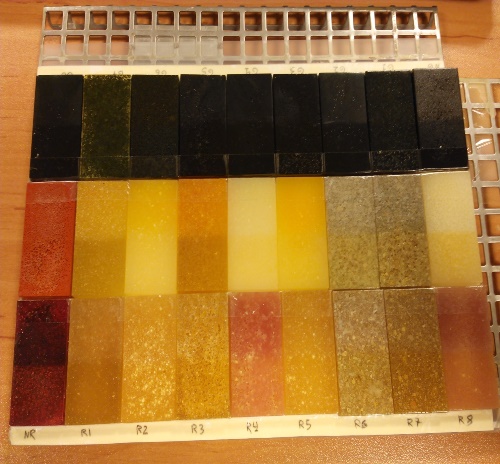

Another advantages, is that it can be obtained a wide color gamut from the same dye molecule, changing the synthesis process conditions. It also can be obtained different texture properties, depending on the nanopigment synthesis factors (Figure 3, Figure 4 and Figure 5).

Figure 5. Epoxy bioresin nanocomposites, with chlorophyll nanopigments, from different synthesis process.

It has been developed a novel method for synthesizing nanostructured hybrid nanopigments. Furthermore, it has been optimized the conditions of the synthesis in order to achieve the best optical, thermal and mechanical properties in materials in which these nanopigment could be applied on.

The method allows:

• It reduces the additives incorporated in the composite generation.

• It reduces the manufacturing composite cost.

• It maximizes the adsorbed organic dye (natural or synthetic) by nanoclays.

• It increases the degradation temperature of the organic dyes.

• It increases the polymer matrix degradation temperature.

• It improves the final material mechanical properties.

• It adjusts the transparency and colouring power of the synthetized material.

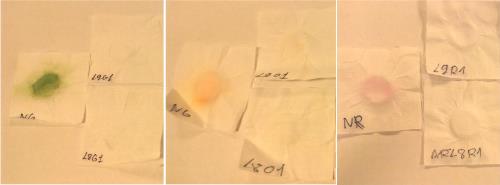

• It increases the degradation by UV-Vis light fastness of the coloured materials (Figure 6).

• It avoids the migration dye from the composites materials, by wet or dye friction (Figure 7).

The technology has been developed on a pilot scale.

It has been done different characterization tests in order to evaluate the process of the

synthesis performance, the reinforcement produced by the dye-clay interactions, the mechanical, optical and thermal properties of the materials in which they were applied the nanopigments. It has been used natural components in the nanopigment synthesis, and in the matrix materials, or binders (Figure 8, Figure 9 and Figure 10).

It has been tried their technical and economic viability.

This technology is focusing on the Material Science, in particular, on the nanostructured hybrid pigments synthesis.

These nanopigments are able to provide the best optical, thermal, and mechanical properties of the materials in which it could be applied on. The materials in which this nanopigments could being applied are:

It is looking for companies interested in acquiring this technology for commercial exploitation through:

• License agreement.

• Searching for funding opportunities to new application developments, depending on the specific company requirements.

• Agreements on technology transfer and adaptation.

• To make technical repots and scientific assessment to the company.

• To provide specific customized training to the company requirements.

• To standardize services, calibration, national or international technical standard reports, etc.

• To provide technological support for those techniques that require highly skilled or sophisticated instruments, that are not available to the company.

• Staff exchange for defined periods of time (techniques learning, etc).

• To rent internal equipment to customers who want to carry out their own tests (Department of Optics, Pharmacology and Anatomy infrastructure, or Research Technical Services of the University of Alicante).

This technology is protected through Spanish granted patent:

• Title: “Procedimiento para la optimización de la síntesis de nanopigmentos híbridos”.

• Application number: P201531534.

• Application date: 27th October, 2015.

Construction and Architecture

Pharmacology, Cosmetics and Ophthalmology

Toys

Wood and Furniture

Materials and Nanotechnology

Medicine and Health

Stone and Marble

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959