Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

With specular surfaces, vision problems present a high difficulty due to the reflectance characteristics of these surfaces, where the modulation of the surroundings conditions to the motif is more remarkable. That is to say, two different motifs can get confused under different surrounding conditions.

The problem to solve is to determine if a product is diverted form the manufacture specifications. That is to say, the task to do is to determine if a pattern is diverted from the variables established in the design phase. In other words, a pattern will be defined by a set of variables (shape, colour, reflectivity, topography, etc.). Any deviation from the established magnitudes in the object will determine another faulty pattern. According the variable or variables that are diverted we will be talking about a specific kind of faulty: morphologic, chromatic, topographic, etc. For example, if the colour variable that describes the object changes with regard to the established one, we will say that we are in view of a chromatic faulty.

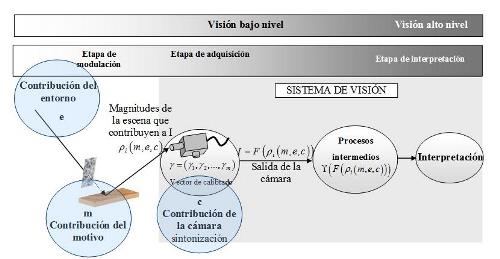

Figure 1. The process of visual perception

As regards the model process matters, the system proposal is the comparison of inspection images or simple characteristics taken from them that allow evaluating the motif variables that are deviated from the specification established in the design phase. The comparison can be done on images of the motifs without defects that will be stored in data bases. This give us general solutions in the face of the use of heuristics related with shapes, kind and the rest of characteristics of the objects. In the development of the model are always considered efficiency and speed.

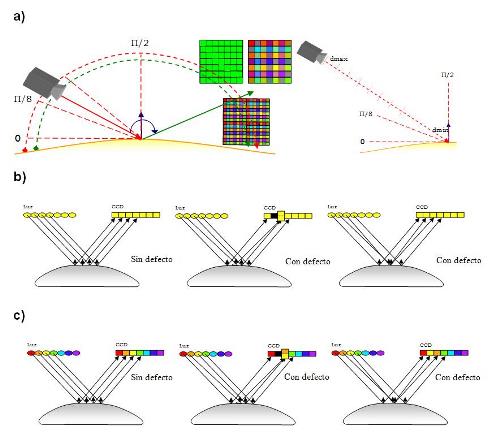

Figure 2. Study of parameters to amplify defects . a) Configuration of angles and distances of perception. b ) Configuration homogeneous light. c ) lights configuration with different wavelengths

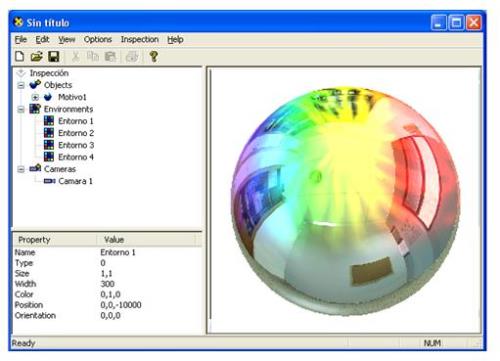

The prototyping tool for inspection of reflective surfaces systems must simulate all the inspection process phases. Therefore, it must give realistic images from particular surroundings, motif and calibration conditions. Moreover, it must implement the inspection defined in the model. Once simulated it must extract several conclusions about the perception scale of the objects, angles, illumination conditions, etc. that will allow to define the prototype.

Figure 3. Graphic Simulator for realistic image synthesis

MAIN ADVANTAGES

When the surfaces show predominance of the specular reflection and not of the diffuse, as occurs with metal-faced products, enamelled, plastic-coated, etc. the discrimination between reflexes and defects is complex even for experts. In general, the inspection done in companies is not very safe due to the variable capacity and experience of the workers, as well as the weariness and the monotony of the work. The automatic inspection vision systems allow a supervision of the products that does not need human assistance and therefore improve the chain value of the companies. These systems improve the productivity and the quality management and give also a competitive advantage to the industries that use this technology. When the inspection is on specular surfaces is even more interesting the automatization.

In particular, the system has the following advantages:

- An important reduction of time cost when analyzing the system and on its development in the assembly line.

- Reduction of economical costs of technological material thanks to the reduction of very expensive physic prototypes needs.

- It allows keeping the knowledge bases about inspection systems (its technology, its processing modules and in general, the designed architecture that can be used to do similar systems).

- It allows reducing defects derived from the analysis phase of the system, design and implementation of real inspection systems and that can be detected at the beginning, before expending too much. Once finished the virtual prototype of the inspection system, the conclusions can be used directly for its physic manufacture or to present feasibility studies.

INNOVATIVE ASPECTS

Even when the prototyping tool is not new in the field of tools to do prototypes, it is new as regards visual inspection systems for specular surfaces. This tool presents a novelty because it allows facilitating the design of inspection systems for specular surfaces: feasibility studies or design of the system. In the tool, the proposed model presents novelties about the way of inspection through the use of a general sketch that can be applied in any area without using heuristics as kind, shape, size, defects, etc. It uses knowledge bases for all the process parts.

The prototyping tool for reflective surfaces inspection systems is currently under development. There is a prototype of the tool that is used to develop inspection systems of chrome-plated surfaces.

The interest is in the development and implantation of quality control systems for industries with problems in the inspection of reflective surfaces.

- Type of partner sought: the group looks for companies or entities interested in adapting the technology to their specific applications.

- Specific area of activity of the partner: companies or entities related to navigation systems or to tourist or guidance activities.

- Task to be performed: the companies that are interested in this particular area of activity should be willing to adapt the technology to their specific needs as well as to finish the parts of the technology that need a further development.

The software is protected by copyright.

The research team of this project belongs to the research group of “Industrial Computing and Computer Networks” of the Computer Technology and Computing Sciences Department from the University of Alicante. The research fields of the group are artificial intelligence, control, vision and networks. They have carried out several contributions that are applicable in industrial contexts (artificial vision systems, mobile robots control, design and computer-assisted manufacture) and in images and systems modelling with biomedical origin (diagnostic and classification).

The team is formed up by four doctors and three computer engineers that are now finishing their doctorate thesis in issues related to the image treatment and computer vision. The team members have a high experience in managing and participation in research projects with funding both public and private.

The former projects and the current ones in which the researchers have participated have been financed by public organizations as the Ministry of Education and Science, the Ministry of Science and Technology or the Presidency and the Culture, Education and Sport Department of the Valencian Government. At present, the group has four projects: “Vision by outer intelligent robot for autonomous mobile systems” financed by the Ministry of Science and Technology, “Computing Palaeontology: data management and computing applications development in palaeontology”, “Architecture model specialized in computing geometry processing” and “Quality control of glossy and reflective surfaces by artificial vision” financed by the Culture, Education and Sport Department of the Valencian Government.

Engineering, Robotics and Automation

Toys

Wood and Furniture

Materials and Nanotechnology

Stone and Marble

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959