Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Design in Engineering and Technological Development (DIDET) group from the ArtefactosLAB laboratory of the University of Alicante has developed a device that allows to comfortably pick up a crutch when it falls to the ground without the user releasing the other crutch or bending down in order to avoid falls.

The aim is to improve the autonomy and quality of life of people with functional diversity thanks to the great opportunities offered by 3D printing and three-dimensional modelling.

The group is looking for companies or institutions interested in continuing this work of social innovation by developing the device or in the design and manufacture of new ones.

Currently, there is no similar device in the assistive technology sector. When a user using two crutches with functional diversity drops one of them to the ground in any daily activity, a dangerous situation arises for the user, since immediate recovery is necessary to avoid loss of balance and/or falls. In many cases the user does not have the functional flexing capacity and/or freedom of movement to recover it, so he/she needs the external help of another person to do so.

3D printing or additive manufacturing has become an alternative manufacturing process to the conventional one, a technique usually used in engineering for the generation of prototypes but which has now been introduced in many sectors for short series due to the low cost of required materials and equipment, its great flexibility and capacity for customisation. The use of other manufacturing processes would increase costs (due to the low number of manufacturing units required), making the possibility of manufacturing any device unfeasible. For people with functional diversity, additive manufacturing is a great advance as it offers viable products at a productive level, accessible to many of those who need them and customised for each user.

Therefore, the need arises to develop a discreet and inclusive device, easy to handle autonomously and affordable, to provide greater autonomy and safety for users using two crutches.

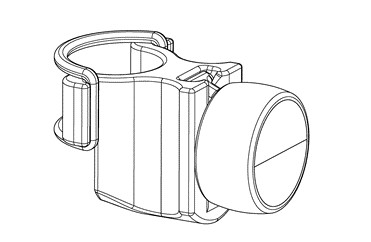

The device consists of two parts; on the one hand, the base which allows it to be attached to the crutch and, on the other hand, the magnetic box, which acts as a support for the magnetic magnet, which is perfectly coupled to the base by means of a guide and which in turn is attached to the base by means of a coiled cord (see Figure 1).

The base comprises a flexible body with a cylindrical finish on the back to allow it to be attached to the crutch, where it has a hook on each side to hold an elastic ring that allows it to be attached to the crutch. In the middle area, on each side, the base has a concave channel, which allows the cord to be held and wound around the perimeter of the base, thus achieving a more intuitive and ergonomic collection of the magnetic box. On its front side there is a T-shaped rail (female) that allows the magnetic box to be attached to the magnetic box.

The magnetic box comprises a flexible ring that encloses two symmetrical pieces that share a hollow cavity, preferably cylindrical, which allows the magnet to be housed inside. Each of these pieces, at the rear, has a T-shaped (male) rail, preferably curved, for coupling to the base, and two holes for holding the cord.

Figure 1: Perspective view of the device.

MAIN ADVANTAGES OF THE TECHNOLOGY

This device has a number of outstanding advantages:

• Very easy installation on any crutch. All you have to do is manually open the elastic ring on the base, position the base at the top of the metal tube of the crutch and stretch the ring while wrapping it around the crutch tube until it reaches the hooks that act as a lock. A pair of devices, one on each of the crutches, must be installed for the collection system to work properly.

• The magnetic box also allows the user to reach other metal personal assistance accessories to further prevent the user from bending over and avoid the risk of falling.

• Very intuitive use. When one of the crutches falls, the user must disassemble the magnetic box from the base, to do so, the user must lift this piece following the guide that joins them and unwind the cord that connects them. Once the magnetic box has been released, the box is dropped, holding the cord until it reaches the other device installed on the other crutch. When the magnetic connection with the even device is made, the fallen crutch is lifted until it can be reached with the other hand for recovery. Once the whole process has been completed, for safety reasons it is necessary to bring the device back to the starting point. To do this, the cord must be wrapped around the base through the channel provided for this purpose, and the magnetic box must be attached to the base through the corresponding rail.

• The material of the base is flexible and non-slippy, allowing it to adapt to crutch tubes of different sizes (between 17 and 21 mm) and, therefore, to create a correct mechanical connection between the device and the crutch. As for the magnetic box, it is made of two materials, a more rigid and stable one that allows the magnet to be housed with consistency; and another flexible material that surrounds the box and allows to absorb impacts that may occur during the use of the device.

• Its geometry allows the customization of the device, as there is a flat circular space on the front of the magnetic box in which any bas-relief text can be incorporated.

INNOVATIVE ASPECTS

3D printing, together with the use of three-dimensional models, has become an alternative manufacturing process to the conventional one. Its application within assistive technologies opens up endless possibilities to improve the quality of life of people with functional diversity, mainly due to the following factors:

• Low cost of required materials and equipment.

• Freedom of design that allows to approach personal needs.

• Manufacturing speed.

• Manufacturing anywhere in the world, giving the user or rehabilitation professional the possibility of self-manufacturing and customising the device, which also means savings in logistics and distribution.

A prototype has been developed based on the participation of different people with functional diversity with whom the dimensions and performance of the device have been tested and adjusted (see Figure 2). It is therefore a device that perfectly meets the intended objectives.

Figure 2: Prototype device

It is primarily aimed at the assistive technology sector and improving people's quality of life. 3D printing is a technique that can be applied to satisfy any need, in any field, that a person may have. It is especially useful for people with functional diversity with very personal problems in fields such as medicine, education, employment or mobility.

From ArtefactosLAB, the DIDET group is looking for companies or institutions interested in supporting the development of crutches or in the design and manufacture of other new devices for social purposes.

This technology is protected by patent application:

• Patent title: “Dispositivo recoge muletas”.

• Application number: P202130249

• Application date: 22/03/2021

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959