Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Spanish and Italian researchers have developed a device to irradiate solid or liquid samples with microwaves (MW) and/or ultrasounds (US). The device allows the user to irradiate samples simultaneously, consecutively or alternatively, with both kinds of energy, but always directly over the sample. The system may be used for improve and reduce time consuming in the sample preparation step in an analytical process. The device has been successfully used for the rapid and efficient determination of the COD (Chemical Oxygen Demand). The researchers are interested in transfer the design and manufacturing know-how of this device to companies involved in analysis equipment; and design and manufacture this device particularly for any company/institution interested.

This system is constituted by a device capable of directly irradiate of a sample, with microwaves (MW) and ultrasounds (US). MW and US radiations can be simultaneous and/or alternatively used. With solid samples, the system is able to obtain a solution by digestion or extraction. With liquid samples it’s possible to carry out liquid-liquid extractions, with suitable solvents.

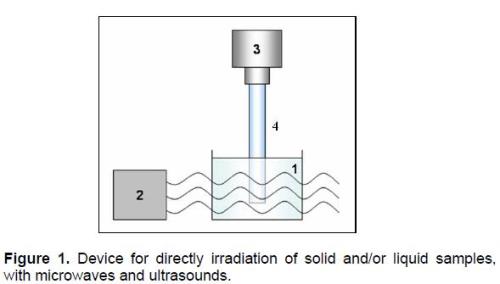

The system consists in three fundamental parts, which are shown in Figure 1:

1. The solid or liquid sample container (1).

2. Microwaves source. The radiation is guided to the sample (2).

3. Ultrasounds generator (3), with a glass sonotrode (4), transparent to microwaves.

The system allows to irradiate a solid or liquid sample with microwaves and ultrasounds, directly over the sample. The two kinds of radiation can be emitted simultaneously, alternatively or consecutively.

The reaction mixture contains the solid or liquid sample, and the needed reagents to carry out the desired chemical process (i.e., digestion, extraction, synthesis,…). The container with this reaction mixture is introduced in he microwaves cavity, where it will be irradiated during a fixed period of time. It’s possible to irradiate simultaneously with ultrasounds, introducing a glass cylinder (sonotrode) in a 4 cm hole performed in the microwaves cavity. This cylinder (sonotrode) is chemically and mechanically resistant and transparent to microwaves. It is introduced directly in the reaction mixture and the ultrasound generator is turned on. In this way, it is possible to irradiate the sample directly and simultaneously with both types of energy.

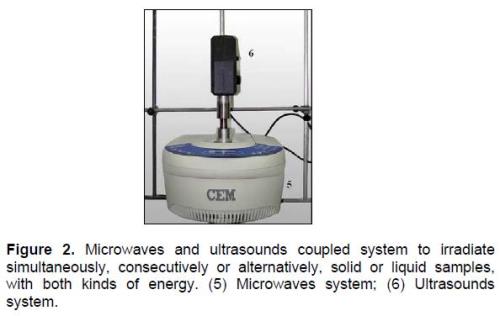

The microwaves and ultrasounds coupled system is shown in Figure 2.

To avoid microwaves leaks during the process through the sonotrode hole, it is important to put a metallic o-ring over the hole. This o-ring is a filter for microwaves and it’s a security for the worker. The o-ring must be 5 cm thickness, at least.

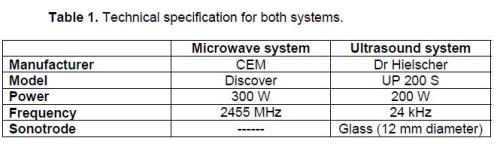

To assemble the coupled device, two commercial equipments have been used: a microwave system and an ultrasounds system. The technical characteristics of both devices are shown in Table 1.

MAIN ADVANTAGES

This device ensures the following properties:

• Easy management.

• Security.

• Effectiveness.

The system offers a novel configuration which allows the device to be used in a very wide range of applications. In addition, the system allows to reduce the time and sample consumption, and is easily to automate and handling.

INNOVATIVE ASPECTS

Presently, alternative products to this technology are available in the market. It is possible to irradiate samples with microwaves and ultrasounds, simultaneously, but not directly over the sample. On previously devices, while the sample is being irradiated directly with microwaves, is radiated indirectly with ultrasounds, using a liquid medium to transfer ultrasound energy.

So the main novelty of this device is to irradiate simultaneously or alternatively a solid or liquid, but always directly over the sample. With this device, it’s possible to improve the efficiency of the chemical processes (liquid-liquid, solid-liquid or gas-liquid extractions, sample digestions, synthesis,…).

A laboratory prototype is currently available for testing.There is a prototype in operation and different tests have been carried out.

There are a large number of analytical applications where the sample

preparation is the most critical step. It is a time consuming step and takes place

the major errors in the process.

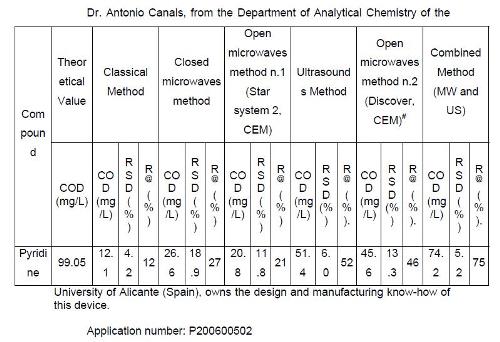

The COD (Chemical Oxygen Demand) determination is one of these

applications. The conventional method is tedious and has some problems. It’s

difficult to oxidize quantitatively some difficult compounds, like pyridine. With

direct and simultaneous irradiation with microwaves and ultrasounds, it’s

possible to reduce the oxidation time and to improve the oxidation efficiency of

difficult compounds (Table 2).

Table 2. Comparison of COD values and relative standard deviation (%)

obtained with different methods.*

* Number of replicates: 5.

This system may be applied to COD determination or any extraction, digestion

or chemical synthesis process. It could be useful in such areas as

biotechnology, food, chemistry, wastewaters, pharmacy and cosmetics.

An agreement on the know-how licence and/or of the patent in order to transfer the rights regarding its use, manufacture or the commercialisation is sought.

Two types of cooperation are sought by the Department of Analytical Chemistry of the University of Alicante:

• Transfer the design and manufacturing know-how of this device to companies involved in analysis equipment that may be interested in its marketing.

• Design and manufacture this device particularly for any company/institution interested.

Application number: P200600502

This technology has been developed by researchers from the Analytical Chemistry Department, in the University of Alicante. One of the main scientific interests of the research team that has developed the device is to suggest new analytical methods or instrumentation prototypes based on microwave radiation and ultrasound energy. In this sense, the team has published six articles on using microwave radiation and ultrasound radiation as a way to reduce time of reaction in sewage COD measurement:

1. Cuesta, A; Todolí, J.L. and Canals, A. “Flow Injection Method for the Rapid Determination of Chemical Oxygen Demand based on Microwave Digestion and Chromium Speciation in Flame Atomic Absorption Spectrometry”. Spectrochimica Acta, 51B, 1791-1800 (1996).

2. Cuesta, A.; Todolí, J.L.; Mora, J. and Canals, A., “Rapid Determination of Chemical Oxygen Demand by a Semi Automated Method Based on Microwave Sample Digestion, Chromium(VI) Organic Solvent Extraction and Flame Atomic Absorption Spectrometry”. Analytica Chimica Acta, 372, 399-409 (1998).

3. Beltra, A.P.; Iniesta, J.; Gras, L.; Gallud, F.; Montiel, V.; Aldaz, A. and Canals, A., “Development of a fully automatic microwave assisted chemical oxygen demand (COD) measurement device”, Instrumentation Science & Technology, 31, 249-259 (2003).

4. Canals, A. and Hernández, M.R., “Ultrasound-assisted method for determination of chemical demand”, Analytical and Bioanalytical Chemistry, 374, 1132-1140 (2002).

5. Canals, A.; Cuesta, A.; Gras, L. and Hernández, M.R., “New ultrasound assisted chemical oxygen demand determination”, Ultrasonics Sonochemistry, 9, 143-149 (2002).

6. Domini, C.E.; Hidalgo, M.; Marken, F. and Canals, A., “Comparison of three optimised digestion methods for rapid determination of chemical oxygen demand: closed microwaves, open microwaves and ultrasound irradiation”, Analytica Chimica Acta, 561, 210-217 (2006).

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959