Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Applied Petrology Group of the University of Alicante has developed an automatic device and a method to determine gas diffusion coefficients of single gases from a gas mixture under atmospheric conditions. The device works in a wide range of relative humidity and temperature and can be employed to test any permeable or porous material.

The procedure allows to calculate the gas diffusion coefficients for samples with different size and nature (soils, rocks, concretes, synthetic materials, etc.). It is a non-destructive test that can be used to calculate the gas diffusion coefficients of more than one gas at the same time. It is looking for companies that are interested in this technology for its commercial exploitation.

Diffusion is the movement of a molecule in a gas mixture as consequence of an existing concentration gradient. This mechanism constitutes the principal gas transport mechanism through porous materials.

Diffusion is quantified through the gas diffusion coefficient of the gas. In porous materials, this coefficient depends on the material type, its pore structure and its water content.

The estimation of the diffusion coefficient has a great interest from a scientific and technical point of view, although it has been mainly carried out by indirect methods.

Although there are some different methods for measuring gas diffusion coefficients (soil columns in which a concentration gradient is forced, employing a gaseous tracer; or plastic membranes via forced diffusion chambers), most of these methods run under constant conditions, which cannot be modified. Thus, for example, temperature conditions or the volumetric water content in the samples cannot be varied during the tests. Therefore, the influence of these parameters in the gas diffusion coefficient cannot be established, although they are a paramount importance.

This invention solves the above mentioned problems. It allows to determinate the gas diffusion coefficients of, at least, one gas present in a gas mixture (either, homogeneous or heterogeneous), when the gas moves through a porous or permeable material. The material can be tested under different conditions such as compacting degree (soils, rocks, concretes, synthetics materials, etc.), humidity degrees and a wide range of temperatures. This device reproduces, in a laboratory scale, real conditions.

The sample is placed in a sealed cell between two vertical differentiated chambers. An automated injection of the gas under study is performed in one of the cells, keeping constant the gas concentration in this chamber during the whole procedure. A probe measuring gas concentration is installed in each chamber, as well as temperature and relative humidity probes. The diffusion process is well guaranteed due to the concentration gradient between the two chambers.

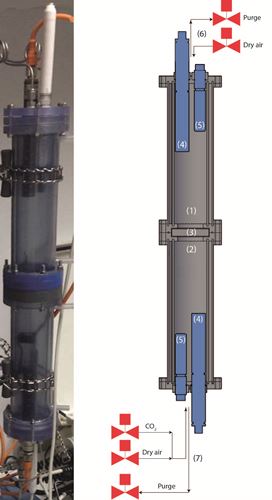

To determine the gas diffusion coefficient, the laboratory device works following the gradient method. This method assumes that gas flux across the soil achieves a steady-state even though the gas concentrations in the chambers change with time. The device has an automatic control system to guarantee the experimental conditions set up by the user and a valves system, which allows the entry and gas outlet (Figure 1).

Figure 1. Laboratory device designed to measure gaseous diffusion. (1) Top chamber. (2) Bottom chamber. (3) Chamber to allocate the sample. (4) Gaseous concentration probe in the bottom and top chamber. (5) Temperature and relative humidity probe in the top and bottom chamber. (6) Set of valves: gas entry, gas outlet and purge in the top chamber. (7) Set of valves: gas entry, gas outlet and purge in the bottom chamber.

The device works at atmospheric pressure for the whole experiment. The different steps are:

1. Allocate the sample in the correct chamber (3).

2. Start the gaseous injection in the bottom chamber (2), after establishing the humidity, temperature and gaseous concentration for the required test. The device runs under different procedures: by continuous gas recirculation, with a particular gaseous

composition; or by using the automatic valves system in order to control each of the gas components of the gas mixture.

3. Keep all the chambers (bottom, top and chamber to allocate the sample) at the same pressure (atmospheric pressure) for the whole experiment. The diffusion mechanism is well guaranteed when there is no change in the chamber pressure.

4. Determine the variation of gas concentration in the top chamber (1) from the beginning to the end of the test. The system will record the time taken for the top chamber to reach the equilibrium with the gas in the bottom chamber. The test finishes when the equilibrium between concentrations in both chambers is accomplished.

5. To determine gas diffusion coefficients, numerical treatment of the data obtained from the experiment is required.

The main advantages and the novelty of the presented device are:

• The device allows the calculation of the diffusion coefficient of a single o multiple gas components in a gas mixture, under different environmental conditions of humidity and temperature, reproducing real conditions. It determines the effect of the environmental parameters in the diffusion coefficient.

• The device works with samples with different size and composition.

• It is a non destructive test. The sample is not altered during the test.

• It is possible to test different gases simultaneously. For instance, water vapor (employed in the test to achieve the humidity required), and other gas as carbon dioxide (CO2), ozone (O3), methane (CH4), etc.

• It allows testing samples which cannot be tested in situ.

• The device works in different modes: short and repetitive cycles, long cycles, etc.

The technology has been developed at laboratory scale, and the method has been proved to be reliable and reproducible enough.

A physical prototype is available for demonstration (Figure 1).

This invention is appropriate to the field of Material Science. The device has been designed in order to determine gas diffusion coefficients in a wide range of environmental conditions and for multiple samples with different size and composition.

For instance:

• Soils.

• Rocks.

• Concretes.

• Synthetic materials.

The device would result useful in:

• Construction materials analysis.

• Geochemical gases prospection.

• Geochemical studies of the gaseous movement through soil and rocks.

It is looking for companies interested in this technology for its technological exploitation through:

• Licensing agreement of the patent.

• Hunt of funding opportunities to develop new applications, to adapt the device to some particular requirements, etc.

• Technology transfer agreement.

• Perform technical reports and scientific support to the companies.

The present invention is protected through granted patent:

• Title: “Equipo para la medición del coeficiente de difusión de gases a través de un material poroso en condiciones reales”.

• Application number: P201531678.

• Application date: 19th November 2015.

Pollution and Environmental Impact

Geological and Geophysical Studies

Stone and Marble

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959