Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

In Gas-Assisted Injection Moulding (GAIM), gas is injected into a mould that has been partially filled with polymer. The gas drives the molten polymer core further into the mould, until it is filled completely. The penetrating gas leaves behind a polymer layer at the mould walls, yielding a product with a polymer skin and an inner gas channel. GAIM offers a number of advantages over conventional injection moulding. They mainly originate from the negligible pressure drop in the gas core: reduced clamp force, reduced sink marks, reduced residual stresses and shorter cycle times. The Chemical Engineering Department of the University of Alicante has applied successfully a complete CAE software package in order to give mould design guidelines and select the optimum process conditions. We are seeking companies to provide us our high experience, expertise and know-how to produce parts that demands the best quality.

In the plastics processing area, gas-assisted injection moulding is a relatively new process that is experiencing rapid growth. Sometimes it is incorrectly positioned as a quick-fix for a problem application. Although GAIM is a variation of injection moulding, it is sometimes confused with blow moulding. This is because both processes feature parts with hollow sections. One major difference between the processes is in the hollow section content of the part. Gas-assist moulded parts have a much thicker wall surrounding a relatively small amount of hollow core. In general, gas-assist moulded parts have less than 10% weight reduction in the hollow sections. Blow moulding, on the other hand, can result in 80% or more hollow sections.

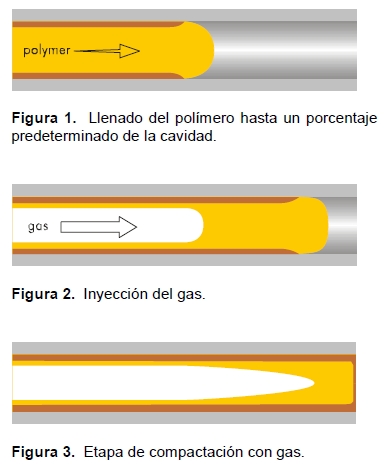

The typical gas assisted injection moulding (short shot process) can be described by a simple three-step process (Figures 1 to 3). A short shot of molten polymer initially fills 75-98% of the mold cavity under the ram speed control of the injection molding machine (Fig. 1). After a short delay period, compressed nitrogen gas cores out the molten polymer, filling the remainder of the mold (Fig. 2). The third step (Fig. 3), or the gas packing stage, occurs as a result of the volumetric shrinkage of the polymer melt. As the plastic solidifies, the gas expands into the volume created by shrinkage, locally packing out the part.

CAE

The use of computer aided flow analysis in the case of gas assisted injection moulding can be of great help to the part designer, mould maker and processor in the determination of parameter such as:

- Gas channel design.

- Percentage of polymer to be injected and its optimal injection point.

- Gas injection locations.

- Preset pressure for gas injection.

- Filling patterns and operating conditions for optimal polymer thickness.

- Best quality surface and minimal shrinkage and warpage.

Computer Aided Engineering (CAE) require three basic inputs: material data (such as viscosity, thermal properties, thermodynamic relationships, and mechanical properties), a finite element model of the part and mould geometry (including gates, runners, and cooling lines), and processing information (such as filling time, gas injection time, and gas pressure). Gas-assist simulation predictions depend on accurate representation of variables of the plastic system.

KNOW-HOW

Due to the sensitivity of gas flow to the design and process variables, computer-aided engineering technique is adopted in the design phase to evaluate the key parameters that may affect the process dynamics.

The department of Chemical Engineering has acquired a complete set of commercial packages to simulate this technology. In CAE topic, the most laborious step is the preprocess. This stage consists in prepare the CAD model to be analysed by a finite element method. For this reason, our department has brought a commercial package called GiD which has been developed by CIMNE (Internacional Centre for Numerical Methods in Engineering). We are costumers of the leader in plastics process simulation, Moldflow ltd. The University of Alicante is working with the last release of the software Moldflow Plastics Insight. Furthermore, we executed structural analysis of the mould injected parts using a finite element software called ANSYS.

ADVANTAGES

Some of the potential benefits of gas-assist injection moulding are:

- Use of lower tonnage machines

- Lower injection pressures

- Improved part quality

- Reduced cycle time vs solid sections

- High strength to weight ratio

- Reduced/eliminated sink

- Less warpage

- Low moulded-in stress provides excellent dimensional stability

- Design flexibility

- Reduced tooling costs as a result of replacing hot runner systems with gas channels.

INNOVATION ASPECTS

Nowadays, commercial packages of Computer Simulation of Gas-Assisted Injection Moulding are available only for thin-walled moulded parts, which are simulated using a midplane model (2½D Hele-Shaw approach). Consequently, it is necessary to create a midplane representation of the complex thick mould cavity. However, for thick parts a midplane representation involves a considerable geometric simplification. Moreover, in some areas of the part it does not exist a unique midplane representation.

A methodology to choose the midplane representation which best fit with the results provided by a three-dimensional computer analysis of the filling stage (conventional moulding) performed with a 3D CAD model of the complex part has been developed and tested.

The simulation results, which have been achieved following the procedure mentioned above, are being confirmed by experiments conducted in Gas-Assisted Injection Moulding trials to manufacture complex geometry thick wall parts (i.e., the fork of a toy bike, in order to replace the traditional metal-made part).

Initial applications in gas-assist injection moulding were primarily closed channel parts such as automobile grab handles and lawn and garden furniture handles. As the technology has sophisticated, design techniques were applied to gas-assist injection moulding, the variety and complexity of applications increased. Next table list examples of these products

Table 1. Gas-Assist Injection Moulding

· Appliance handles

· Toy industry

· Automotive

- accelerator pedal arms

- air filter housings

- door handles

- mirror housings

- oil filler duct

· Business machine chassis / housings

· Furniture: chairs, tables

· Television housings

· Golf club shafts

· Basketball backboards

· CD-ROM trays

· Bottle crates

· Copier panels

· Shower heads

· Washing machine agitators

· Window frames

Two types of cooperation are sought by the Department of Chemical Engineering of the University of Alicante:

· Consulting services for companies which are working or expect to work with GAIM.

· Instruct people interested in perform the tasks involved in gas assisted injection moulding.

The Department of Chemical Engineering owns the know-how to carry out the simulation of Gas-Assisted Injection Moulding. Protection by patent is not applicable.

The research team responsible for this new technology are all members of the Department of Chemical Engineering in the University of Alicante, consisting of: 5 senior professors, 9 full-time professors, 10 part-time professors, 4 assistants, 12 grant-holders and 6 members of the administrative staff. Our main research fields are:

- Pyrolysis, Gasification and Incineration.

- Environmental Water Management.

- Environmental Managemente of Industrial Waste.

- Synthesis and Optimization of Chemical Processes.

- Rectification and Extraction of Multicomponent Mixtures.

- Activated Carbon.

- Balance between Solid-Liquid-Liquid-Solid Phases.

- Holographic Interferometry.

- Polymer Processing.

- Food Technology.

- Time of Stay Distribution in Electrochemical Reactors.

- PCDD/PCDF Detection and Analysis.

Toys

Wood and Furniture

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959