Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The University Institute of Materials of the University of Alicante has developed an ingenious electrochemical reactor that allows the regeneration of spent activated carbon from different industries with an efficiency between 90-100% quickly, selectively, very economically and in the same facilities where the spent activated carbon is located. Moreover, it is an environmentally friendly technology.

This new reactor has two possible configurations and is very versatile, since it allows the regeneration of more than 100 kg. of activated carbon saturated with pollutants from different industries, such as: wastewater treatment, water purification, gas and liquid purification, metal recovery, food and beverage production, chemical and pharmaceutical industry, etc.

It is looking for companies interested in acquiring this technology for its commercial exploitation through patent license agreements.

Activated carbon adsorption is a mature and advanced technology that allows remove organic and inorganic pollutants from different industries (water treatment, gas emissions, etc.).

Growing demand in the reuse of water along a more restrictive environmental protection legislation has caused the global production of activated carbon to increase annually about 10% -reaching a market share more than 6,100 million dollars in 2018, and with a forecast of more than 11,500 million dollars in 2025-.

Activated carbon technology presents several problems, the main ones being those related to the handling and management of activated carbon once it has reached its useful life, that is, when the adsorption capacity of the activated carbon is partially or totally exhausted, and therefore, from that moment on, it must be considered as a highly contaminating waste. Therefore, to use activated carbon at industrial level, a technical and economical viable reactivation or regeneration process is required. Moreover, it is necessary that initial porosity of the original carbonaceous material to be restored, as well as appropriate management to ensure the sustainability of the entire adsorption process.

Currently, there are four different technologies for regenerating spent activated carbon:

1) Thermal regeneration (in an inert atmosphere or in oxidizing conditions): it has a regeneration efficiency of 85-90%.

2) Chemical regeneration.

3) Microbiological regeneration.

4) Vacuum regeneration.

These technologies have the following disadvantages:

• They have a high energy consumption (0.53 kWh/kg in the case of thermal regeneration).

• The original porosity of the coal is modified due to undesired gasification reactions which causes a loss of raw material -between 10-20% per treatment-.

• Polluting gases are released to the environment.

• They have high transportation costs because it is a process that is carried out in specific independent facilities (ex-situ).

• The number of companies that have capacity to regenerate activated carbon is very limited.

The main method to regenerate spent activated carbon that exists currently is thermal process. It stands out for its high economic and energy cost, it is aggressive with the environment, and it requires the addition of new activated carbon after each treatment to achieve final porosity that is desired.

In order to reduce the problems mentioned above, other alternative methods have been developed, among which the electrochemical regeneration method stands out.

Electrochemical regeneration is characterized by its high performance in regeneration, by its lower energy consumption, by the low cost of treatment, by its environmental friendliness, and by its versatility to regenerate other adsorbent materials (zeolites, etc.).

In this sense, an industrial reactor has been developed for electrochemical regeneration of spent activated carbon, which comprises two possible configurations: with concentric cylindrical electrodes and with parallel plane electrodes, both electrodes separated through an ionic membrane. An electrode is placed in each compartment, which can act as an anode or cathode depending on the process requirements. The electrolyte needed to carry out the electrochemical regeneration has its input at the bottom, and the output at the top of each compartment.

At present, all the studies of electrochemical regeneration have been carried out at laboratory scale using commonly used electrochemical reactors, and the prototypes developed at pilot plant scale only allow to regenerate a maximum of 6 kg. of saturated activated carbon with a solution of two contaminants under very controlled conditions.

At an industrial level, only one technology has been developed that allows the adsorption of the contaminants in NyexTM and the electrochemical destruction within a single reactor.

The lack of studies carried out with spent activated carbons in real situations, the laboratory scale used in the design (from grams to 6 kg.), and the absence of industrial scaling processes, mean that at this time, any alternative recovery method to thermal regeneration lacks a viable industrial application.

In order to overcome the limitations described above, an industrial reactor has been developed that allows the electrochemical regeneration of activated carbon that is partially or totally saturated with organic and inorganic contaminants.

This reactor allows two possible configurations:

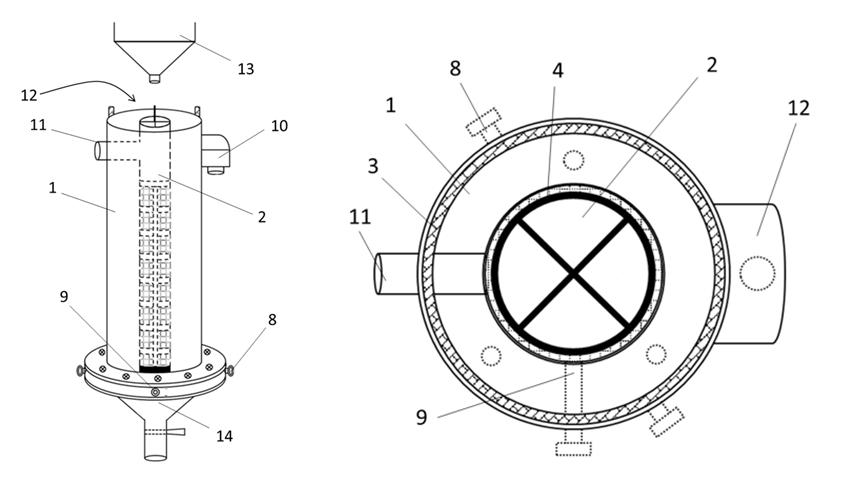

a) With cylindrical concentric electrodes (see Figure 1):

Figure 1: schematic view -front and top, respectively- of the electrochemical reactor in concentric cylindrical electrode configuration.

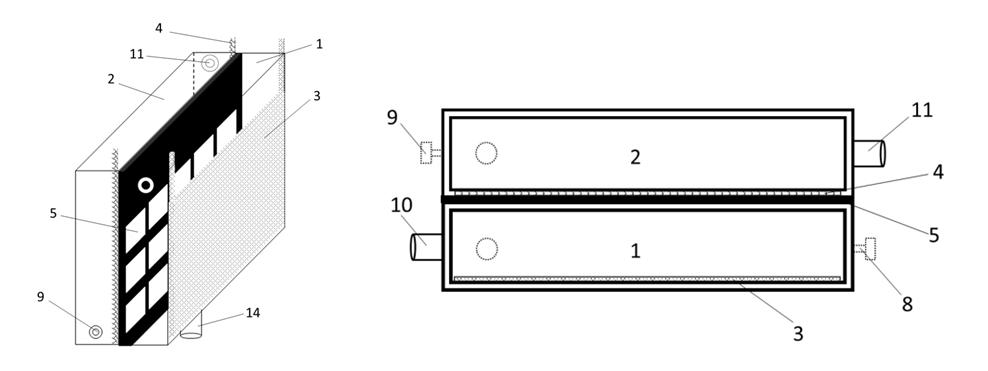

b) With parallel plane electrodes (see Figure 2):

Figure 2: schematic view - in perspective and above, respectively - of the electrochemical reactor in parallel plane electrode configuration.

The electrochemical reactor comprises two compartments (1,2) separated through an ion exchange membrane (5), each one with an electrode (3, 4) and connected to two independent electrolyte recirculation circuits from two electrolyte tanks (6,7), an upper inlet (12) of the activated carbon to be regenerated from a tank or hopper (13), and a lower outlet (14) of regenerated activated carbon.

Stainless steel, platinized titanium (Pt/Ti), ruthenium oxide (RuO2/Ti) and iridium oxide (IrO2/Ti), among others, can be used as electrodes (3,4). In general, stainless steel will be used when the electrode acts as a cathode.

In both cases (a and b), the electrochemical reactor is built by the same elements (only the structural configuration varies). The main difference is the shape of the compartments: in the parallel plane configuration (b), both compartments (1,2) are rectangular prisms, and the first electrode (3) is placed in the intermediate panel. The ion exchange membrane (5) can be in an intermediate sector that is not part of any of the compartments (1,2).

The following variables must be taken into account in the procedure for electrochemical regeneration of spent activated carbon:

• The type of electrolyte: acid, basic or neutral.

• The concentration of the electrolyte.

• The type of regeneration: anodic or cathodic.

• The flow of work.

• The current density.

• The time of residence.

• The treatment of activated carbon in the reactor.

ADVANTAGES OF THE TECHNOLOGY

The electrochemical regeneration of spent activated carbon is characterized by the following advantages over current methods:

1) One of the reagents used are electrons, so it can be easily supplied by a direct current source.

2) The process can be immediately interrupted.

3) It can be applied in the same facilities where the material to be regenerated is located (in-situ).

4) It has a high selectivity.

5) Less carbon dioxide (CO2) emissions are emitted.

6) It has a lower energy consumption than thermal regeneration.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

Unlike current methods of regeneration, this new electrochemical reactor allows recovery any type of spent activated carbon used in different industrial sectors -water and gas treatment, pharmaceutical and chemical, etc.- at pilot plant and industrial level in real conditions.

Therefore, currently, this novel electrochemical reactor is the only available on the market that allows in-situ regeneration of exhausted activated carbons in the 10-15 kg. scale, which it can be easily scaled to more than 100 kg.

Different treatment conditions have been tested in the electrochemical reactor -in both configurations and with different chemical nature electrodes- where the regeneration variables of exhausted granular activated carbon from water treatment plants have been optimized.

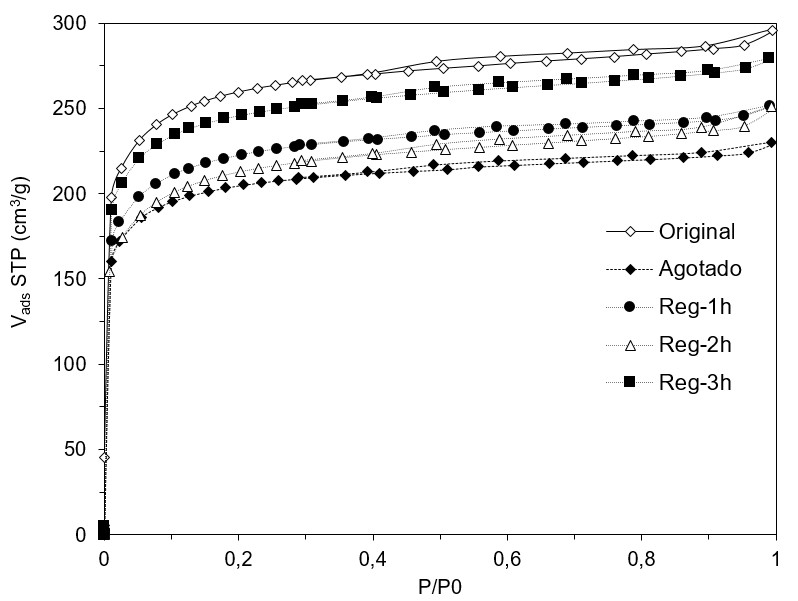

In all the cases, an efficiency in the electrochemical regeneration between 90-100% in less than 3 hours has been achieved (see Figure 3), with energy consumption of the process between 0.035-0.061 kWh/kg, 10-15 times less than current 0.53 kWh/kg of the thermal regeneration.

Figure 3: graphic of nitrogen adsorption-desorption isotherms at -196ºC from a depleted activated carbon electrochemical regeneration experiment. The symbols represent: (hollow rhombus with continuous line) is the original activated carbon, (rhombus filled with dotted line) is the exhausted activated carbon, (circle filled with dotted line) is the activated carbon taken in the first hour of treatment, (hollow triangle with dotted line) is the activated carbon taken in the second hour of treatment and (square filled with dotted line) is the activated carbon taken in the third hour of treatment.

This novel electrochemical reactor can be used in the same facility where the application of the activated carbon occurs (in-situ), or it can be transported to another location (ex-situ).

Two pilot plant scale prototypes (TRL=6) are available for demonstration (see Pictures 1 and 2).

Two industrial prototypes have also been built (TRL=7) that allow the electrochemical regeneration of spent activated carbon in 100 kg batches.

Picture 1: electrochemical reactor front view in parallel plane electrode configuration -15 kg. treatment capacity-

Picture 2: electrochemical reactor front view in concentric cylindrical electrode configuration -10 kg. treatment capacity-

This technology allows electrochemical regeneration of spent activated carbon from different industries, including, among others:

• Wastewater treatment and water purification plants.

• Treatment of combustion gases.

• Gas and liquid purification.

• Metals recovery.

• Food and beverage production.

• Pharmaceutical sector.

• Chemical industry.

• Synthesis of catalysts.

It is looking for companies interested in acquiring this technology for commercial exploitation through patent license agreements.

Company profile sought: Spent activated carbon regeneration.

The present invention is protected under patent application:

• Title of the patent: "Reactor electroquímico para la regeneración electroquímica de carbón activado".

• Application number: P202030510.

• Application date: 1st June, 2020.

Pollution and Environmental Impact

Pharmacology, Cosmetics and Ophthalmology

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959