Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Carbonaceous Materials and Environment research group at the University of Alicante has developed an innovative active packaging that makes use of waste from the food industry. These containers are made from activated carbon obtained from waste and have an excellent capacity to adsorb ethylene. Therefore, it is an ideal solution to delay the ripening of fruit and vegetables, making use of agri-food waste.

This technology is very interesting for agri-food companies that want to reuse their waste and generate products with high added value.

Companies interested in acquiring this technology for commercial exploitation are sought.

Currently, a third of the world's food for human consumption is wasted. In Spain, fruit is the product that is most wasted along with vegetables. The development of conservation technologies is essential to reduce this waste.

Fresh food products have characteristics of conservation and maturation specific to the specific product, but limited in time. In addition to being stored in optimal environmental conditions to preserve its preservation, packaging is a fundamental element in maintaining the shelf life of food.

There are different strategies to promote their conservation in packaging, from the addition of preservatives to the use of special containers. This is the case of active packaging, which has special properties that promote the stability and preservation of the food contained inside.

One of the factors that accelerate the ripening of fruits and vegetables is ethylene, a compound that they generate naturally during their metabolic process. The adsorption of this compound would increase the shelf life of the food.

In recent years, the research group has generated advanced knowledge in the use of activated carbons for use in food packaging.

In particular, work has been done on the generation of activated carbons that are incorporated into the packaging and that have high ethylene adsorption performance. The adsorption of this compound delays the ripening process of food.

To generate these activated carbons, the group has worked with agri-food waste. This biomass waste is transformed into activated carbons through a procedure designed by the researchers.

This process incorporates a series of improvements with respect to the techniques used so far since it allows a more efficient synthesis which results in lower costs, higher yield, shorter processing time and a lower amount of activating agent. The material obtained is more stable, harmless and integrated into the packaging itself.

In this way, food processing waste can be reused to make the containers in which the same processed food will be stored, providing them with a greater conservation capacity.

All this achieves a high degree of reuse of waste, giving it a new added value and generating a circular economy solution.

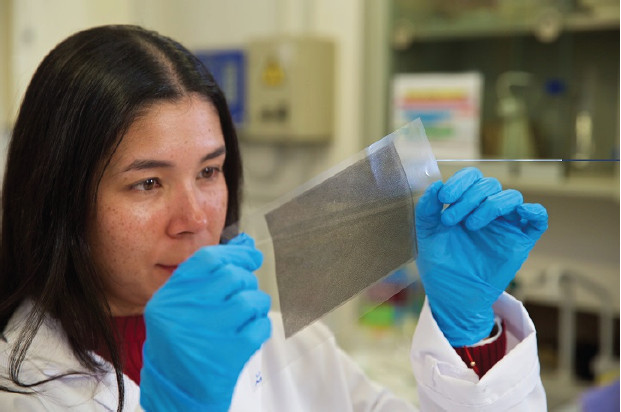

Fig 1. Film developed incorporating activated carbon

MAIN ADVANTAGES OF THE TECHNOLOGY

This technology has multiple advantages:

• Possibility of reusing waste that has no value and that generates an economic and environmental cost.

• The active packaging can adsorb the ethylene gas generated by food and which causes the acceleration of the degradation process.

• Increases the shelf life of food.

• Contributes to the overall reduction of food waste.

• The new process has a series of technical advantages over its predecessors, such as:

o More efficient method in which moisture content is not a drawback.

o Higher yields

o Shorter processing times

o Lower temperatures required for processing.

o More stable material

o Lower packaging saturation speed

o System integrated into the packaging itself

o Use of more sustainable chemical reagents.

o Possibility of being reused in successive processes.

o Lower replacement frequency due to high porosity

• Around 40% of the waste can be transformed into activated carbon and incorporated into the active packaging

INNOVATIVE ASPECTS

The most innovative aspect of this technology is the possibility of taking advantage of a waste that generates an economic and environmental cost, and turning it into an element of high added value that can be used by the food industry itself to produce food packaging. In addition, this packaging allows the shelf life of food to be increased, thus providing a new competitive element to the company and its products.

All this is achieved with a more efficient process that is easier to implement in the company's own facility.

Fig 2. Packaging generated with new technology

The technology is currently in the validation phase and tests are being carried out with fruits and different agri-food industries to assess the impact on the shelf life of food.

This technology arises from a research project called ENCARBIO financed by the Valencian Innovation Agency (AVI) within the program for the valorization and transfer of R&D&I results.

This technology is particularly interesting for the agri-food sector and, in particular, for fruit and vegetable companies.

• Knowledge licensing agreements.

• R+D (technical cooperation) project agreement to undertake technology-related projects.

Biodiversity and Landscape

Biology

Molecular Biology and Biotechnology

Pollution and Environmental Impact

Pharmacology, Cosmetics and Ophthalmology

Engineering, Robotics and Automation

Materials and Nanotechnology

Medicine and Health

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959