Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Engineering Design and Technological Development (DIDET in Spanish) group of the University of Alicante has developed a clamping device for drawstring backpacks obtained by 3D printing. The aim is to prevent the backpack's strings from slipping down from the shoulders of people with functional diversity and thus improve their autonomy and quality of life. The group is looking for companies or institutions interested in continuing to develop the device or in designing and manufacturing new ones.

Today, within the assistive technology sector (orthopaedics), there is no device for ergonomically carrying a drawstring backpack. The usual joining techniques do not solve either this problem, since they hamper the handling and procedure for placing the backpack for a user with functional diversity, requiring external help of another person.

3D printing has traditionally been a technique used in engineering for the generation of prototypes. Nowadays, it has been introduced in many sectors for short series due to the low cost of materials and required equipment, its great flexibility and capacity of customization. The use of other manufacturing processes would increase costs (due to the low number of manufacturing units required), making the possibility of manufacturing any object or device unfeasible.

With all this, it is necessary to develop a device to ergonomically carry a drawstring backpack without the strings slipping off the shoulder, with an inclusive design, affordable and allowing autonomous handling, even with difficulty in the mobility of the upper limbs or the absence of one of them.

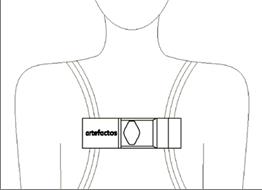

The device is composed of a single solid or flexible and resistant body, where from its central part two surfaces emerge folded on themselves, one of them includes a snap-in mechanical locking system and the other one a free opening (see Figure 1).

The locking system may be a light pressure female-male socket system, a dovetail system or an equivalent locking system, which combined with the mechanical characteristics of the flexible material in which it is manufactured allows easy opening and closing, while resisting traction and movements by the user without opening.

On the front of the central part, the device has a housing that corresponds to a universal 90º clamping system for interchanging the user's personal assistance accessories.

Figure 1: Perspective view of the device where you can see the different parts that make it up (central body, closing side, free opening side and housing for personal aid accessories).

Regarding its operation, the end of the snap-in lock is opened and slightly raised to introduce the drawstring backpack strings over one of the shoulders and by making a slight pressure on the female-male clamp, it is closed again. The other end is where the user introduces and removes the other strings from the backpack (from the opposite shoulder), with an open movement, very simple and versatile. This action can be repeated as many times as you wish to put on and take off the drawstring backpack.

The clamping device has a number of important advantages:

- It is soft, flexible and pleasant.

- It does not generate pressure on the chest.

- It allows a better and more even distribution of the weight contained in the drawstring backpack.

- The device has a good durability of its main and secondary functions, it is resistant to traction and friction, even to treading on it.

- The design of the device pursues a friendly, integrative and inclusive appearance.

- It can be operated with only one hand, so no external assistance is required.

- The universal attachment of the device allows the use of other personal aid accessories (see Figure 2).

3D printing, together with the use of three-dimensional models, has become an alternative manufacturing process to the conventional one. Its application within assistive technologies opens up endless possibilities for improving the quality of life of people with functional diversity due mainly to two factors:

- Low cost of materials and required equipment.

- Freedom of design that allows to approach the personal needs.

The current device is the result of the participation of different people with functional diversity with whom the dimensions and performance of the device have been tested and adjusted. Therefore, it is a device that perfectly meets the objectives set and is already used on a regular basis by a large number of people of all ages.

3D printing is a technique that can be applied to meet any need, in any field, that a person may have. It is especially useful for those people with functional diversity with very personal problems in fields such as medicine, education, work or mobility.

The DIDET group is looking for companies or institutions interested in supporting the development of the device or in the design and manufacture of new ones.

This technology is protected by a utility model application.

• Title of the utility model: "Clamping device for drawstring backpack obtained by additive manufacturing".

• Application number: U201931890

• Date of application: 15/11/2019

Social Studies

Engineering, Robotics and Automation

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959