Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Design in Engineering and Technological Development (DIDET) group from the ArtefactosLAB laboratory of the University of Alicante has developed a modular system of interchangeable sections to simulate vascular anatomical models of arterial networks customisable for a patient. This invention, manufactured by 3D printing, enables the preparation in greater detail of real interventions of different pathologies such as aneurysms or stenosis.

The group is looking for companies or institutions interested in continuing with this health innovation work by developing the system or in the design and manufacture of other new devices.

Endovascular techniques fall within the context of minimally invasive surgical procedures, which consist of introducing catheters and other elements inside the patient's blood vessels to improve the treatment of certain vascular lesions. They are currently a rapidly developing medical field, allowing for more precise and less invasive diagnostic and therapeutic solutions to complex pathologies. However, the acquisition of skills and technical training in this field is difficult. Simulation with animal models is increasingly outdated and additive design is a promising alternative.

So far, the already known vascular simulator models are two-dimensional, i.e. they lack depth ratio. This allows for simplification of catheter handling but at the same time means loss of reliable correlation with real practice. Therefore, they are based on idealised and simplified theoretical anatomical models, not on real models.

In fact, the major disadvantage of the known models is that they do not allow to represent all the irregularities of the arterial walls, the differences in the internal calibre of the vessels and the anatomical tortuosity that in real interventions condition the vascular accesses and the stability of the catheters.

Therefore, it is necessary to develop a modular system that offers a simple but efficient solution to simulate vascular anatomical models of arterial networks customised for a patient, which accurately represent specific deformations or conditions. In this way, the tactile sensations of real clinical practice can be generated and interventions for different pathologies such as aneurysms or stenosis can be adequately trained.

The present invention makes it possible to reliably reproduce an arterial network from a real anatomical model, as well as to manufacture interchangeable sections that represent pathologies by replicating the lesions as they are. This enables more detailed preparation of real interventions to decide with greater certainty on the appropriate material and the best approach for each individual case.

The system consists of two parts: the base, which supports the arteries and gives stability to the system as a whole, and the arterial network, which simulates the real vascular anatomy and is attached directly to the supports of the base by pressure.

The base consists of a laminar body with holes, preferably made of rigid, translucent material, which, when viewed in plan, partially or completely simulates the contours of the anatomy of the human body.

As for the arterial network, the interchangeable sections representing the arteries (healthy or with pathology) form a three-dimensional geometry that is completely faithful to the anatomical reality of the patient.

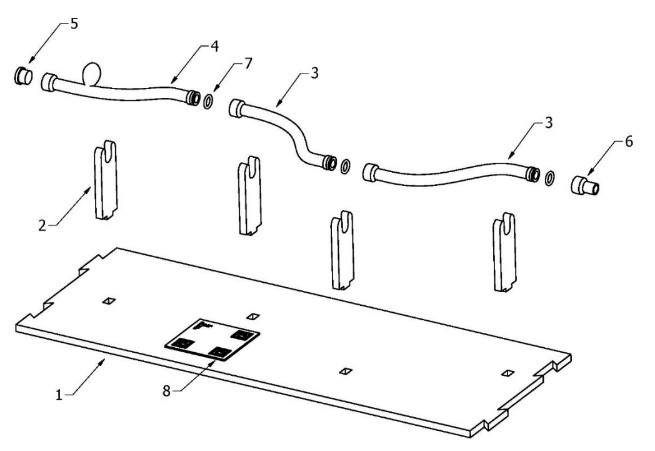

In more detail, the modular system consists of the following elements (see Figure 1):

The base comprises a laminar main body (1) and supports (2) that fit into holes located along the surface of the main body (1). On the other hand, at two of the ends of the laminate we find a joining system that allows the different modules (head, thorax, leg,..) to be joined together until a whole body can be constructed. Optionally, a QR code or similar (8) is attached to the surface of the main body (1) to act as a marker in an augmented reality system.

The arterial network is made up of sections of healthy arteries (3) made of rigid material and sections of arteries with pathologies (4) made of flexible material so that their surface shows deformations, joined together by means of quick and registrable joints.

The arterial network is press-fitted to the supports (2) of the base. Once the arterial network is attached, the device has two types of endings, plugs (5) and plugs with inlet (6), which are joined, like the arteries, by means of an O-ring to guarantee watertightness. These plugs allow the filling and emptying of the arterial network fluid together with a pump that generates the circulation.

Figure 1: Components of the modular system of interchangeable sections.

The steps involved in the development and production of a modular system of interchangeable sections for vascular simulation are described below:

• Analysis of the clinical case and definition of the simulation project.

• Acquisition of the patient's own biomodels.

• Design and 3D modelling of the system.

• Production of the modular system of interchangeable sections for vascular simulation using 3D printing.

• Post-processing of the interchangeable sections that create the arterial network.

• Assembly and validation.

MAIN ADVANTAGES OF THE TECHNOLOGY

The present invention has great advantages:

• The modular system can partially configure a part of the anatomy (head, leg, arm, etc.) or the entire human body by joining the different modules together. This versatility makes it possible to cover different medical specialities.

• Quick assembly and disassembly of both the modules and the interchangeable sections allows, on the one hand, didactics in training workshops, and on the other hand, customisation of the device with real patient pathologies (aneurysms, stenosis, etc.). This increases the quality of medical training, promotes surgical planning and improves patient care, all of which leads to a reduction in operating theatre and hospitalisation times, with a consequent reduction in hospital costs.

• In terms of surgical planning, it provides significant value in the neuroradiology field, as it allows complex clinical cases to be analysed to create 3D biomodels based on medical imaging techniques of the patient.

• The interchangeable sections are made of transparent material, allowing the interventional physician to locate the position of the lesion or pathology and manoeuvre with the corresponding instruments along the arterial network in a visually direct manner. In addition, the material of the interchangeable sections is radiolucent, which allows them to be viewed by radiology equipment in the hospital environment.

INNOVATIVE ASPECTS

3D printing, together with the use of three-dimensional models, has become a productive alternative in the traditional industry. At present, they are offering solutions to technical problems in industry, healthcare and even those that affect people's quality of life. Particularly useful for short series as they offer great flexibility and the possibility of customisation. This is the case of the present invention which, within 3D printing, uses stereolithography (SL) technology to manufacture parts using high-performance resins that are stable, resistant, durable and with good precision.

After manufacturing, it is essential to carry out an exhaustive chemical washing of the interchangeable sections, inside and out, until the resin remains are completely eliminated from the sections, prior to curing by UV radiation. This guarantees the quality of the interchangeable sections produced.

Optionally, the modular system of interchangeable sections can form part of an augmented (or mixed) reality system that allows the patient's body to be virtually visualised together with all the digital information necessary for the clinical practice of the intervention. To this end, the base incorporates an identification code (QR or other) on its surface that allows it to act as a marker in the augmented reality system.

Therefore, it is a manufacturing process that is characterised by the low cost of the materials and equipment required, as well as the possibility of being produced quickly anywhere in the world with the consequent savings in logistics and distribution.

A prototype has been developed with the participation of different medical specialists who have tested and adjusted the dimensions and performance of the simulator (see Figure 2). Therefore, a device that perfectly meets the objectives sought has been achieved.

Figure 2: Detail view of the arterial network of the prototype

It is primarily aimed at the healthcare technology and innovation sector for the improvement of medical training and surgical planning.

3D printing or additive manufacturing is a technique that can be applied to satisfy any need, in any field, that a person may have. It is especially useful for people with functional diversity with very personal problems in fields such as medicine, education, work or mobility.

From ArtefactosLAB, the DIDET group is looking for companies or institutions interested in supporting the development of the system or in the design and manufacture of other new devices for social or health purposes.

This technology is protected by patent application:

• Patent title: “Sistema modular de tramos intercambiables para simulación vascular y procedimiento de fabricación de los tramos intercambiables”

• Application number: P202131127

• Application date: 03/12/2021

Engineering, Robotics and Automation

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959