Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Analytical and Circular (bio)Chemistry Research Group (bioCir) at the University of Alicante has developed an efficient and sustainable method for extracting lignin from agro-food waste, such as coconut husk. This innovative method combines ultrasound and deep eutectic solvents (DES), achieving lignin extraction of at least 80% of the waste in a reduced time.

The combination of the chemical action of DES and the effect of ultrasound enables efficient dissolution and extraction of lignin. This sustainable and scalable method represents an innovative alternative to valorize agricultural waste within a circular economy model.

The technology, protected by a patent application, has been developed at laboratory scale. The solid lignin obtained through this method could be used as a raw material for various industrial applications, including the chemical, pharmaceutical, cosmetic, and advanced materials sectors. Companies interested in commercial exploitation are sought.

Every year, 1.3 million tons of food are wasted globally. In Spain, fruits and vegetables are the most commonly discarded foods. Additionally, each Spaniard generates around 460 kg of urban waste per year. To reduce this impact, a more sustainable system is essential—one that better utilizes resources and reuses waste.

Among this waste, lignin stands out. It is present in structural parts of plants such as peels, leaves, and stems. Its extraction is relatively simple and does not require costly processes. Lignin is found in hard fruit skins, stalks and trunks of corn and sugarcane, fruit pits, nutshells, and cereal residues.

One agro-food waste of great interest is coconut husk, due to its high concentration of lignin—a valuable compound with industrial applications. The coconut, fruit of the palm tree Cocos nucifera, consists of three layers: the exocarp (the outermost and hardest layer, often discarded), the mesocarp (the fibrous intermediate layer), and the endocarp (the inner layer that surrounds the pulp).

The coconut husk, corresponding to the exocarp, is distinguished by its high lignin content, giving it significant utility. Although its chemical composition varies, it generally has a high percentage of lignin and cellulose. Despite its potential for producing natural fibers, biofuels, and sustainable construction materials, large quantities of coconut husks are discarded annually. Extracting lignin from coconut husk represents a strategy to valorize this waste and transform it into a high-value-added product, contributing to sustainability.

Lignin extraction using sodium hydroxide (NaOH) is a common method that requires preparation of the plant material and treatment with NaOH to dissolve the lignin. Although functional, it presents issues and limitations. The processes vary in conditions such as NaOH concentration, temperature, and reaction time, and may include ultrasound. Main drawbacks include the use of chemicals, the need for high temperatures and pressures in some cases, and the optimization of conditions to improve yield.

In recent years, deep eutectic solvents (DES) have attracted interest due to their unique properties, low volatility, reduced toxicity, and biocompatibility, making them attractive for sustainable applications. DES are obtained by combining and heating solids in specific proportions, resulting in a phase change to liquid. Their use has been explored for processing biomass and extracting lignin.

There are procedures for extracting lignin with DES using both conventional heating and microwave methods. However, microwave-based methods have limitations, such as the need for high temperatures, variable yields, limited biomass compatibility, scalability challenges, and the risk of DES degradation.

General limitations of lignin extraction methods, including DES, are low yields, long processing times, and lack of methods to isolate lignin from the extractant. These methods are limited due to interactions of various factors during the process. Uneven heating and limited ultrasound penetration are key constraints, along with pH and temperature.

Therefore, there is a need to develop a sustainable, fast, and efficient method for extracting lignin from agro-food waste. For the process to be attractive, waste materials must have lignin content above 10%, hemicellulose content below 50%, and cellulose content below 55%. In response to these limitations, a methodology is proposed that combines the use of DES with ultrasound, aiming to achieve lignin extraction yields of at least 80% while significantly reducing extraction time.

The Analytical and Circular (bio)Chemistry Research Group (bioCir) at the University of Alicante has developed a new method to obtain lignin, a valuable component, from agro-food waste. This method is not only environmentally friendly but also transforms waste—often discarded—into a useful resource for industry.

This new method uses a combination of sound waves (ultrasound) and special, safe liquids (deep eutectic solvents or DES) to extract lignin. By carefully adjusting the process, a faster extraction is achieved with higher lignin yield than with traditional methods. Moreover, the method ensures that lignin is effectively separated and purified, ready for use.

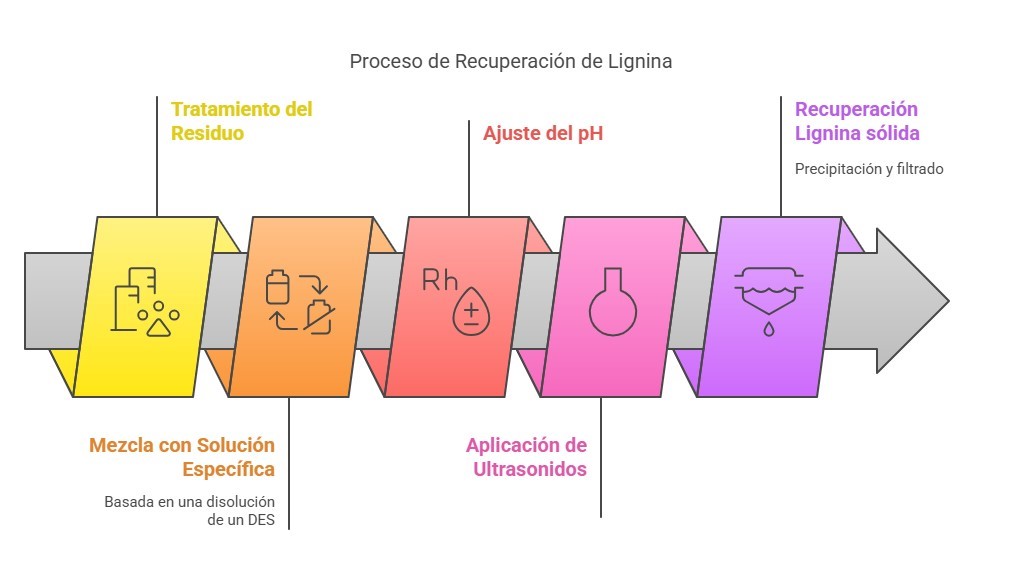

The proposed procedure for lignin extraction from agro-food waste involves several steps, including waste preparation, mixing with a specific solution (including DES), pH adjustment, ultrasound application, and final lignin recovery (Figure 1).

Figure 1. Schematic diagram for obtaining solid lignin from agro-food waste.

It is worth mentioning that the chemical interaction between the components of DES and the functional groups of lignin, along with ultrasonic cavitation, enables efficient release of lignin from agro-food waste—even in complex lignocellulosic matrices.

As a result, the proposed extraction method allows for high yields (at least 80%), ensuring its industrial applicability. Therefore, it lays the groundwork for technology transfer and commercialization of the process, promoting its positive impact both environmentally—by reducing waste accumulation—and economically—by generating a high-value product for various industries.

TECHNOLOGY ADVANTAGES

The main advantages of the technology in terms of sustainability, efficiency, and competitiveness are:

• Higher yield and efficiency: The combination of deep eutectic solvents (DES) and ultrasound allows for lignin extraction above 80%, outperforming conventional methods.

• Faster processing and lower energy consumption: Process optimization significantly reduces extraction times, saving energy and resources.

• High selectivity and product purity: The obtained lignin has lower contamination from other biomass components, making it more suitable for advanced industrial applications.

• Industrial scalability: The method is adaptable to larger-scale processes without requiring costly investments in specialized equipment.

• Reduction of agro-food waste: The technology enables the use of lignin-rich waste, such as coconut husk, avoiding landfill accumulation or uncontrolled burning.

• Substitution of aggressive solvents: Unlike traditional processes with sodium hydroxide (NaOH) or other polluting chemicals, the use of DES minimizes hazardous waste generation.

• Lower ecological impact: The methodology reduces the carbon footprint of the extraction process by lowering energy consumption and avoiding aggressive chemicals.

• Contribution to the circular economy: Transforms waste into high-value raw material, fostering sustainability in sectors like chemicals, cosmetics, and advanced materials.

• Replacement of fossil-derived compounds: The lignin obtained has the potential to replace petroleum-derived polymers and additives in multiple applications, supporting the transition toward a more sustainable industry.

• Sustainability differentiation: Companies in the chemical, pharmaceutical, or advanced materials sectors can enhance their environmental reputation by incorporating sustainably extracted lignin.

• Opportunities in green markets: The demand for sustainable and bio-based products is growing, offering competitive advantages to early adopters of this technology.

• Feedstock flexibility: The methodology is adaptable to different types of lignocellulosic waste, allowing implementation across various regions and supply chains.

INNOVATIVE FEATURES OF THE TECHNOLOGY

The main innovative aspects of this technology are twofold: the combined use of DES and ultrasound for lignin extraction and the achievement of high-purity lignin with fewer impurities.

The integration of DES with ultrasound in a single process represents a significant innovation in lignin extraction. While DES offer a sustainable and highly efficient alternative to conventional solvents, ultrasound accelerates disruption of the lignocellulosic matrix and enhances mass transfer, optimizing extraction. This synergistic combination not only improves recovery yield but also reduces energy consumption and minimizes chemical waste generation, setting it apart from traditional methods based on aggressive reagents like sodium hydroxide or volatile organic solvents.

Unlike other extraction technologies, this method isolates lignin with a more preserved chemical structure and lower polysaccharide and contaminant content. The higher purity of the final product broadens its applicability in advanced industrial sectors without requiring additional purification steps. This is a key competitive advantage, reducing processing costs and enhancing the versatility of the extracted lignin.

These innovative aspects position this technology as an efficient, sustainable, and highly adaptable alternative for agro-industrial waste valorization, opening new opportunities in the development of bio-based materials and products.

The results obtained demonstrate lignin extraction above 80% from analyzed agro-food waste: coconut peel and pineapple crown and shell.

The lignin obtained could be used as a raw material in industrial applications, including the chemical, pharmaceutical, cosmetic, and advanced materials sectors.

Lignin extracted through this technology presents characteristics that make it suitable for diverse industrial applications in both established and emerging markets. The main application areas include:

• Chemical industry

• Advanced materials

• Cosmetic and pharmaceutical sector

Beyond these current sectors, the purity and versatility of the obtained lignin open opportunities for developing new materials and products within the circular bioeconomy, contributing to the replacement of fossil-derived products in various industrial applications.

Companies are sought to acquire this technology for commercial exploitation through:

• Patent licensing agreements.

• R&D collaboration agreements to tailor the technology to company needs.

• Proof-of-concept projects.

• Scientific-technical advisory services.

• Etc.

Target companies:

• Companies producing biopolymers and/or sustainable materials.

• Chemical industry specializing in lignin derivatives.

• Manufacturers of natural cosmetics and pharmaceuticals.

This technology is protected by a patent application.

• Patent title: “Method for extracting lignin from agro-food waste with lignin content above 10%, hemicellulose content below 50%, and cellulose content below 55%.”

• Application number: P202530213.

• Application date: March 12, 2025.

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959