Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group of Plant Pathology at the University of Alicante has developed a new process by using fungi to produce biofuel (bioethanol) and fungal biomass for agrobiotech use from shellfish waste. It is a sustainable alternative to agroforestry crops currently used.

The current technology stands out because it uses chitosan as the sole source of nutrients, and produces bioethanol in profitable, sustainable and environmentally friendly manner.

The research group is looking for companies or investors partners interested in acquiring this technology for commercial exploitation.

The decline in oil reserves is raising interest in biofuels as alternative to fossil fuels. Liquid or gas biofuels are obtained from biomass. Biodiesel and bioethanol are the only biofuels currently produced and used on a large scale worldwide. Bioethanol is the most widely used biofuel. In fact, data on Bioethanol production is increasing with a total production in the United States in 2011 of 52,617 million liters, a 4.5 % increase versus 2010.

Current biofuel production is mainly carried out by yeast fermentation (eg. Saccharomyces cerevisiae) of plant raw material with high sugar content. Yeasts have high growth potential under fermentative conditions since they tolerate high concentrations of substrate and they are highly resistant to the ethanol than they themselves produce. However , the use of plant raw materials for biofuels poses serious economic, social and environmental problems due to the necessary increase in the cultivated area for this purpose. In this sense, the high demand for agricultural biofuels would be a huge effort to produce sufficient raw material, which would in turn adversely affect food price and availability.

To solve these problems, it is advisable to use alternative substrates to crops that would allow high biofuel production at competitive costs. Agroforestry, industrial or fish waste are potential raw materials for biofuel production.

However, most of these residues require pre-treatments (for example, chemical or enzymatic pre-digestions) prior to yeast fermentation that complicate production and increasing costs.

In the other hand, chitin is one of the most abundant biopolymers on Earth. It is a key component of the exoskeleton of many invertebrates (insects, crustaceans, molluscs, nematodes), and of the cell wall of true fungi. Shellfish waste (especially marine crustaceans) is an abundant and readily available (a fishing industry by-product) source of chitin. Since it is nitrogen rich its disposal has a negative environmental impact, mainly due to ammonia toxicity.

Chitosan is a chitin derivative with high antimicrobial activity spectrum (bactericidal and fungicidal), useful both in medicine and agriculture. However, chitosan has not been used as biofuel raw material, since traditional fermenting organisms (eg. Saccharomyces cerevisiae), are sensitive to chitosan and therefore unable to use it. Consequently, new strategies to use chitin waste which would reduce its negative environmental impact are needed.

We have developed a novel process for producing biofuel (bioethanol) and fungal biomass for sustainable crop pest management as by-product. This novel process can use waste from the shellfish industry (or other sources of chitin or chitosan), as an alternative raw material to the use of crops or agroforestry residues.

Our process is a sustainable way to eliminate the pollution caused by shellfish waste. We use nematophagous and entomopathogenic fungi which are able to grow efficiently in anaerobiosis, producing ethanol from the reducing sugars obtained from chitosan, chitin or their derivatives (produced as a result of the degradation of the shellfish industry waste). These nematophagous and entomopathogenic fungi are:

Fungi (as conidia and chlamydospores) are at given concentrations that allow rapid and abundant growth without producing self-inhibition.

ADVANTAGES OF THE TECHNOLOGY

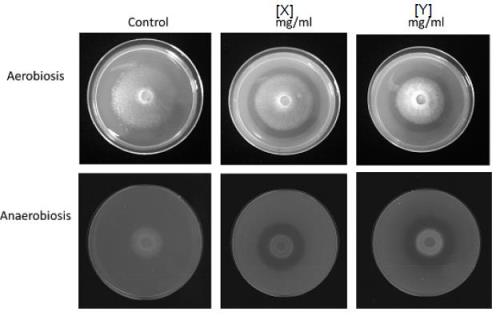

• Fungi can grow under high chitosan concentrations (more than 2 mg/ml), which are toxic to other microorganisms conditions, thus reducing culture contamination.

• Fungi use chitosan as a sole source of nutrients.

• Fungi produce a large amount of reducing sugars which are fermented into ethanol.

• Fungi can grow under anaerobic conditions.

• Fungi are able to tolerate the amount of ethanol that they themselves produce in the culture medium (no self-inhibition occurs).

• Fungi encode in their genomes zinc-dependent alcohol dehydrogenases and pyruvate decarboxylases that are required to produce ethanol.

• Fungi produce ethanol and fungal biomass from chitosan rich residues of the shellfish industry, thus reducing pollution they cause.

• The process is sustainable and environmentally friendly.

• It is profitable process.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

We have developed a new procedure for producing biofuel (ethanol) using shellfish industry waste and nematophagous or entomopathogenic fungi. It is a sustainable non-food alternative to crops or agroforestry waste processed, instead of the traditional fermentation processes.

We have obtained under laboratory conditions up to 2% ethanol by growing aerobic and anaerobically nematophagous and entomopathogenic fungi (Pochonia chlamydosporia, Beauveria bassiana, Metarhizium anisopliae) with chitosan as only nutrient source.

The research group has the know-how to scale-up and improve their results to pre-industrial level to show their full potential and profitability.

This technology is part of the field of Biotechnology . It is a novel process for ethanol and fungal biomass production as by-product using entomopathogenic and nematophagous fungi and a source of chitosan.

Applications:

• Biofuel production (bioethanol) as an alternative to ethanol produced by fermentation processes (using yeast) from plant as raw material.

• Production of fungal biomass for sustainable crop protection.

• Biodegradation and decontamination of shellfish industry waste (the high nitrogen content of this waste leads eutrophication, so that its uncontrolled disposal has serious environmental problems).

Companies or investors partners interested in acquiring this technology for commercial exploitation through:

• License agreement of the patents.

• Search for funding opportunities to develop new applications adapted to the specific needs of the company.

• Technology and knowledge transfer agreements.

• Technical reports and scientific advice services.

• Standardization, calibration, development of national and international technical standards.

• Provide technical support in those techniques that require highly skilled personnel or sophisticated instruments that are not available for the applicant.

• Staff exchange for defined time periods (eg. for learning a technique).

• Rental own equipment to customers who wish to conduct their own tests (through own infrastructure of the Department of Marine Sciences and Applied Biology or Common Research Facilities (SSTTI) at the University of Alicante).

The present invention is protected through 3 granted patents:

Patent 1:

Patent 2:

Patent 3:

The research group of Plant Pathology at the University of Alicante was created in 1990 (http://www.fungalinteractions.org/). Research in the group aims at understanding the mode of action (at molecular, cell and ecological levels) and practical development of biocontrol fungi. The group also works on the endophytic behaviour of nematophagous (especially the nematode egg-parasite Pochonia chlamydosporia) and entomopathogenic fungi (mainly Beauveria bassiana), and their implications in biocontrol and plant growth promotion. The research group also worked on the role of fungal root endophytes in natural vegetation under stress and their applications. The group is currently researching about chitosan (a seafood waste product) as a fungicide for human pathogenic fungi and yeast, and its compatibility with biocontrol fungi. After the genome sequencing of Pochonia chlamydosporia the lab is currently developing the fungus as a cell factory for antimicrobial, enzyme and biofuel applications (as this technological offer). These results have been published in more than 100 papers (and book chapters), most of them with high impact in the scientific and technological communities. The laboratory has requested more than 10 patents about the development of fungi (production, formulation) for biotechnological applications. The research group has also developed and patented the interactions of fungi with chitosan applicable to control fungal pathogens or to enhace biocontrol fungi. It has been also patented the application of biocontrol fungi in plant growth/development promotion. The plant pathology group actively collaborates with Spanish and international research groups (Germany, Central America, Australia, Brasil, Canada, Finland, Holland, Italy, United Kingdom, Russia and the USA), as well as with prestigious companies.

Biology

Molecular Biology and Biotechnology

Pollution and Environmental Impact

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959