Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

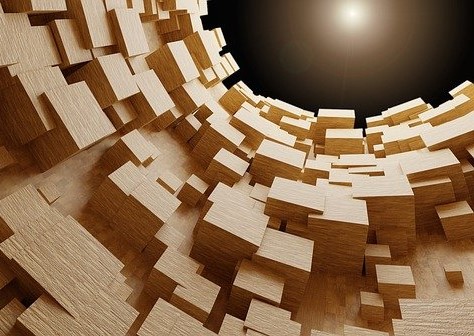

Researchers from the Department of Civil Engineering at the University of Alicante have developed a new system to build wooden constructions in a fast, resistant and efficient way without the need to use metallic elements (steel), adhesives or concrete, thus increasing the useful life of the wood.

This system is modular and therefore reduces the assembly time of the house. As it is a standardised and automatable process, it is also possible to reduce manufacturing time and costs.

The system, which is protected by a patent application, has been developed on a laboratory scale and would therefore require further development for its market introduction. Companies in the wood construction sector interested in a possible commercial exploitation of the technology are sought.

Currently, there is a growing tendency to replace classic materials such as concrete and steel with much more environmentally friendly construction materials, with wood standing out above the rest. In order to achieve this, a structural system must be created that promotes the use of wood as a structural element, as it is an agent that reduces environmental impact and is capable of storing one tonne of CO2 in its interior for every cubic metre of wood.

There are several known ways of making joints between pieces of wood:

• Inserting a metal part, nail or screw, which fixes both pieces. However, this type of part generates stress in the wood and can end up breaking it.

• Inserting two metal parts, which fit together so as not to affect the wooden parts.

• Using wooden studs that are inserted into holes in both parts.

• Fixing with adhesives.

• Generation of teeth on both parts that are attached to each other.

Each of these fixings offers its own advantages but does not achieve enough strength. Therefore, there is a need to develop a method to join pieces of wood in a simple, fast and strong way that avoids the disadvantages of the currently used systems, especially avoiding the use of metal reinforcement elements in order to increase the lifetime of the wood.

Researchers from the Department of Civil Engineering at the University of Alicante have developed a new, fast, resistant and efficient way of joining pieces of wood without using metallic elements (steel), adhesives or concrete.

The joint for wood fixes two pieces together, with the first piece being a box and the second piece an inlet. In addition, the box has a first part of greater width and a second part of decreasing width.

The shape of the recess is conjugated to the second part of the box, while the walls of the second part and the recess have complementary teeth which can be sinusoidal or trapezoidal. The first teeth can be made with a milling cutter. It comprises a central shank and a series of radial protrusions that create the valleys between the first teeth.

The weight of the parts themselves can hold the joint in the correct position, but it is preferable to have a dowel or stop in the first part of the housing to prevent the return movement of the boss.

If the contact surface is large enough, the strength can be increased by making each part have a box and a boss in opposite orientation. In this way, it is possible to insert both bosses into the respective housings in a single movement. The housing and the boss of each part can be aligned or not (coincident axis of symmetry).

In the mounting position, the two recesses are aligned to ensure that the forces are transmitted without moments. This is achieved by defining steps on the contact surface of the two pieces so that the box and the inlet of each piece are aligned.

In this way, any structure made of wood or similar material is perfectly joined and strong as, for example, a wooden structure for a building.

Finally, it is worth mentioning that tests have been carried out on this type of joint, using pieces in the form of an architectural portico, with a joint at each end of the horizontal bar. This system can replace the current timber and steel structural systems with a structural timber dry jointed system.

ADVANTAGES OF THE TECHNOLOGY

The main advantages resulting from the application of this wood joint are the following:

• The joint is produced without the use of metal reinforcing elements (nails, screws, etc.), thus achieving high strength without affecting the useful life of the wood.

• A fast joint is achieved, which also reduces manufacturing time and eliminates the use of steel in wooden constructions, achieving a dry assembly of parts.

• Fast production due to the fact that the parts are based on an automated system that is capable of reducing manufacturing time and costs.

• Standardisation of parts. Parts can be standardised and manufactured in just a few minutes using a special machining cutter, which means shorter production time and greater control of the process from the start.

• Ease of transport, due to standardised parts, which means that large quantities of material can be transported in a way that saves fuel and postage. The packaging is flat.

• Easy joining of parts due to the mechanised system. Complex assembly tools are avoided and the labour and resources required to assemble the system are optimised. Assembly without the need for metal fittings.

• Sustainable. Wood is a material adapted to the 21st century. It reduces the carbon footprint of construction and is also a highly energy-efficient material.

• The system is modular, which means that the work on site is reduced thanks to the study and manufacture of the houses/buildings in the workshop. Therefore, labour time is reduced and on-site resources are optimised.

MAIN INNOVATIVE ASPECTS OF THE TECHNOLOGY

The main innovative aspect of the present invention lies in the fact that no metal elements, concrete or adhesives are required to join wooden parts, which by means of a composition are made into an industrialised architectural module.

The other major innovative aspect is the curved machining.

The technology has been developed at laboratory scale, with several prototypes available for demonstration and compression values have been tested.

The present invention corresponds to a wood joint that allows two pieces to be joined together in a simple, resistant way and without requiring metallic elements such as nails or screws that affect the life of the joint.

It allows the joining of wooden parts, preferably wooden beams and pillars and wooden crosspieces or joists between beams.

Therefore, this invention is of particular interest for the construction of wooden structures or other structures that make use of wood.

Companies interested in acquiring this technology for its exploitation are sought. Possible type of agreements:

• Patent licensing agreements.

• R&D projects for customised developments.

• Proof of concept projects.

• R&D projects to adapt the technology to the needs of the company.

Type of company sought:

• Manufacturers of wooden building materials.

• Manufacturers of ecological building materials.

• Wooden house builders.

• Companies with wood machining capabilities.

This technology is protected under patent application.

• Patent title: “Wood joint”.

• Application number: P202131185

• Application date: December 21, 2021.

Wood and Furniture

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959