Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group “Physics of condensed matter” of the University of Alicante has developed a new solid state laser (OSL) where the active compound comprises carbon-bridged oligo(p-phenylenevinylene) (COPV).

The main advantages of this technology are photostability, miscibility, processable in thin layers and effective for laser generation at different wavelengths. It can be used in the following industrial sectors: Spectroscopy, biosensors, chemical sensors and optical communications.

The research group is looking for companies interested in acquiring this invention or adapting it to their requirements.

COPVs are new organic dyes with which impediments like photostability, solubility, efficiency and processability in thin layers are largely eliminated, making them unique in many ways among known laser organic systems:

(i) a robust all-carbon skeleton is available here in a homologous series made of the repeating unit, which gives them high emission quantum yield close to unity over the broad range of visible light region (ca. 380–590 nm) as well as high stability against light irradiation and carrier injection,

(ii) a flat and rigid pi-system with strained bicyclo[3.3.0]octene substructure can be excited with low photoexcitation energy, and

(iii) substituents on the bridging carbon atoms and peripositions are available, which allow to equip them with miscibility and dispersibility in matrices.

The system developed comprises a laser device (solid body) containing carbon-bridged oligo(p-phenylenevinylene), COPV.

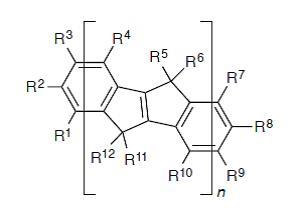

COPV refers to polymers, oligomers, homopolymer, homooligomer and mixed polymer or mixed oligomer (Fig.1).COPV comprise the general formula:

Figure 1. General formula of COPV

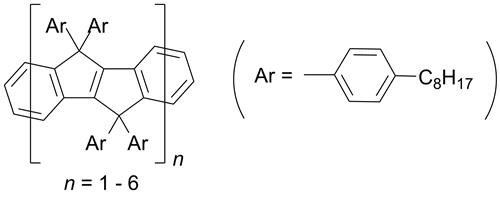

An example of these compounds are the COPVn oligomers (where n is a number between 1-6). See Figure 2.

The laser system developed consists of a device with distributed feedback (DFB), where a thin film, containing COPV is set over a substrate. This substrate is usually composed of glass, melt silica, SiO2 or a polymeric film.

Over this substrate, a solid film is deposited (it can be higher but typical range for thickness could be 0.5-1 µm). This layer is a thermoplastic polymeric material where the COPV has been previously dispersed. A layer of COPV without being dispersed on the thermoplastic polymeric material can also be used. Additionally, an active photosensible layer can also be added (photoresist material).

In the developed system, the relief grating is imprinted on top of the substrate layer, or on top of the additional layer of a photoresist material or on top of the film containing COPV. This can be imprinted by holographic lithography or thermal nano-printing lithography.

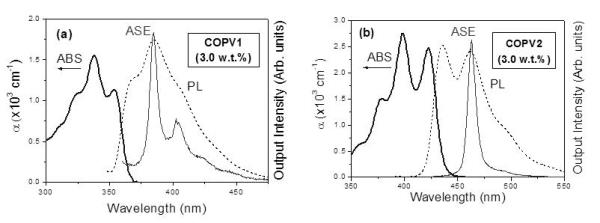

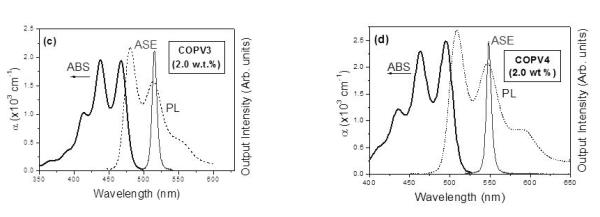

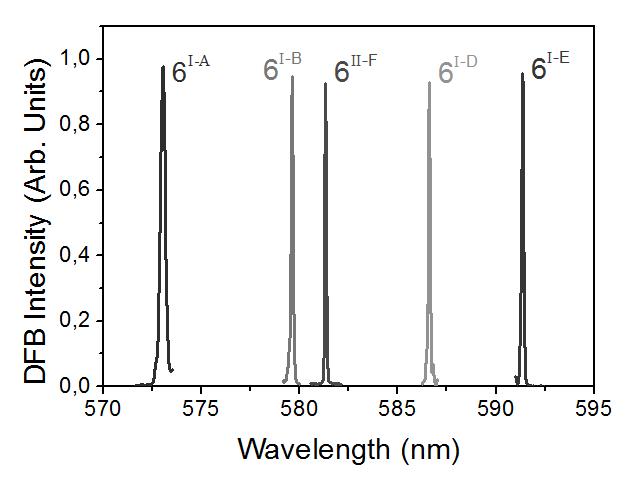

Figure 3. Following figures, from a) to f), show the absorbance (ABS, thick solid line, left axis), photoluminescence and ASE (PL, dashed line and thin solid line, respectively; right axis) spectra for PS films containing a COPVn derivative, for n = 1 to 6, respectively (doping rate indicated in the legend) deposited over bare fused silica substrates (without gratings);

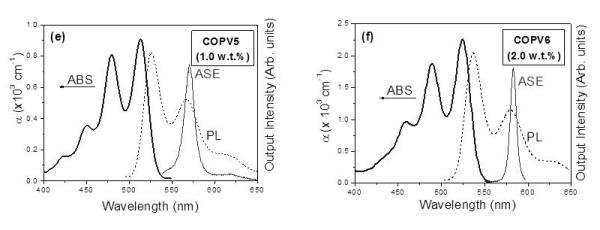

Figure 4. Following figure shows the emission spectra of DFB lasers in which the active film is made of PS and a COPVn compound, for n = 1 to 6.

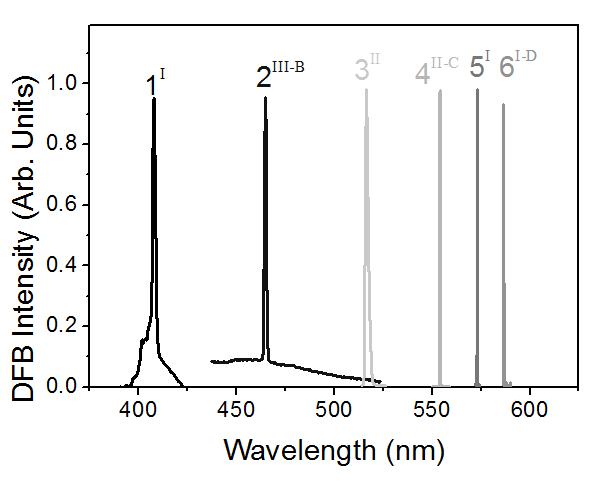

Figura 5. This figure shows the emission spectra of various DFB lasers based on PS films containing COPV6, aiming to illustrate the capability of tuning the emission wavelength for a given COPV derivative, by changing the device active film thickness or the grating period.

MAIN ADVANTAGES OF THE TECHNOLOGY

The laser developed material shows the following advantages :

• Suficientemente soluble y miscible para facilitar la fabricación de películas delgadas. Soluble and miscible in order to allow thin layer processing.

• Cheap.

• Photostable.

• Efficient for laser light generation.

• Ability for emission at different wavelengths.

INNOVATIVE ASPECTS

Same laser development combines:

• Efficiency

• Stability

• Wavelength tuning.

• Liquid solution procesable.

Lab scale.

• Spectroscopy

• Biosensors

• Chemical Sensors

• Optical Communications

Companies looking for technologies in order to commercially introduce or develop this product are sought. Cooperation sought:

• Licensing agreements.

• Joint R&D projects in order to adapt the developed technology to company needs.

This technology is protected by the following granted patent:

• Application number:. P201530954

• Application date:. 02/07/2015

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959