Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The University of Alicante has developed an innovative polyurethane pressure sensitive adhesive (PSA), that presents a controllable degree of stickiness ("tack") with respect to the current adhesives. The tack of the adhesive is changed abruptly in specific short ranges of temperature.

The adhesive is potentially biocompatible and has excellent properties for use in medical applications (dressings, bandages, ...). It can also be used in other applications such as labeling for the transport of goods or refrigerated food.

Applying a slight temperature variation, the adhesive can be easily removed, without generating waste or causing discomfort to the patient.

Pressure sensitive adhesives (PSA) have a wide presence in the market, being widely used in different applications such as adhesive tapes, labels or repositionable adhesives in the food, pharmaceutical, security packaging and automotive industries. They are also commonly applied for medical purposes as they are ideal for their ease of application and adhesion to the skin.

There are different types of PSA adhesives depending on their composition and manufacturing process, such as polyurethane based PSAs, acrylic PSAs, polysiloxane based PSAs, polysiloxane based PSAs, polysobutylene based PSAs, etc.

Polyurethane based PSAs are more hydrophilic than the rest of PSAs and are biocompatible with the skin so they are preferable for medical applications. However, they present an important disadvantage as they have an inherent low tack and low peel adhesion.

The invention developed includes both a new family of PSA adhesives based on thermoplastic polyurethanes and the process for their production.

The adhesive is synthesized by the reaction of isocyanates and polyols, and by controlling the synthesis a good balance between tack, adhesion and cohesion can be achieved. The main characteristic of these adhesives is that by slightly varying the composition and synthesis conditions, specific adhesives are obtained with specific tack ratings that operate in short temperature ranges.

As an example, several formulations have been optimized for specific applications in the following temperature ranges:

• Between 10ºC and 39ºC, focusing on an optimal point of adhesion at 37ºC. At temperatures below 25º its adhesion capacity drops considerably. This adhesive is ideal for use in medical and skin contact applications.

• Between 5ºC and 20ºC. This adhesive is ideal for special applications such as labelling for the transport of goods at room temperature (fresh food, beverages, etc.).

• Between -10ºC and 5ºC. This adhesive also focuses on specific applications such as labelling for the transport of refrigerated goods.

The adhesive developed by the researchers of the university is a pressure sensitive adhesive (PSA) based on polyurethane without the need of adding tackifier, so it has the usual advantages of these adhesives that provide them with excellent conditions for medical use.

In addition, polyurethane PSA incorporates a series of advantages that provide unique features such as the following:

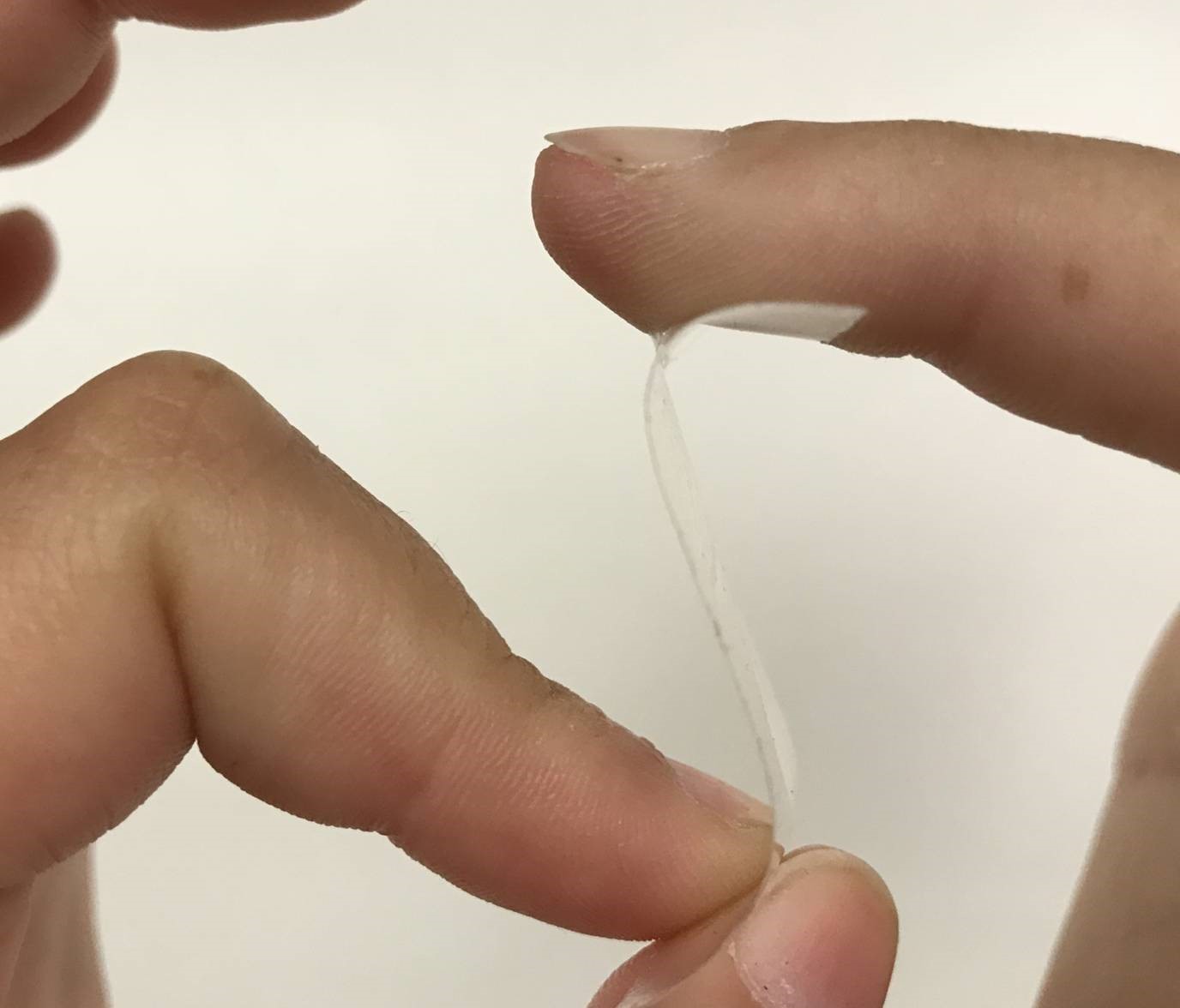

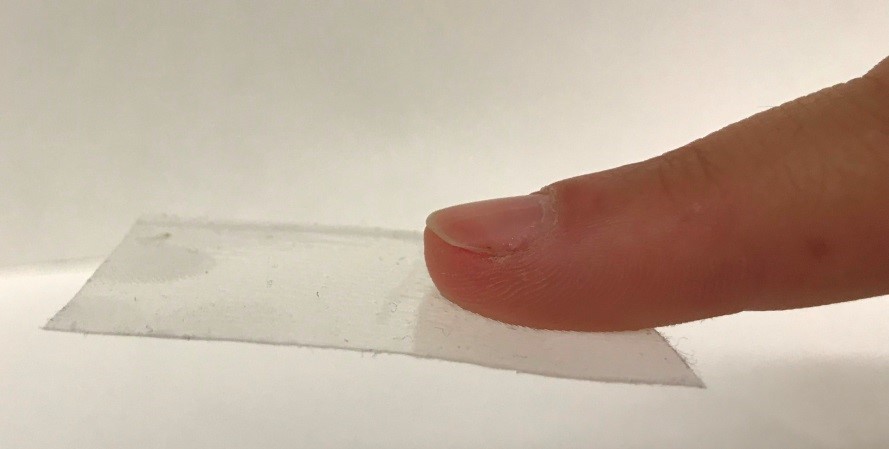

- It presents a permanent stickiness when applying a light pressure with the fingers. It does not require activation for its application, it maintains the joint to the substrate in time and leaves no residue upon removal.

- Polyurethane PSA adhesives are more hydrophilic and biocompatible than other PSA adhesives.

- The developed adhesive shows a good skin tolerance.

- The new formulation has managed to solve the main drawbacks of the polyurethane PSA, i.e., its low tack at room temperature, obtaining optimum adhesion properties, without sacrificing its cohesion.

- The adhesion of the new polyurethane PSA adhesives can be modified in a wide range of values by changing their segmented structure, and the adhesives are completely transparent.

- By varying the synthesis process, the tack can be controlled on demand by customizing the temperature ranges in which the adhesive is active.

- Adhesion can be easily removed by slight variation of the temperature.

Thermoplastic polyurethane PSA adhesives have many advantages for application in industry or the biomedical sector, but their main disadvantage is their low tack and limited peel adhesion.

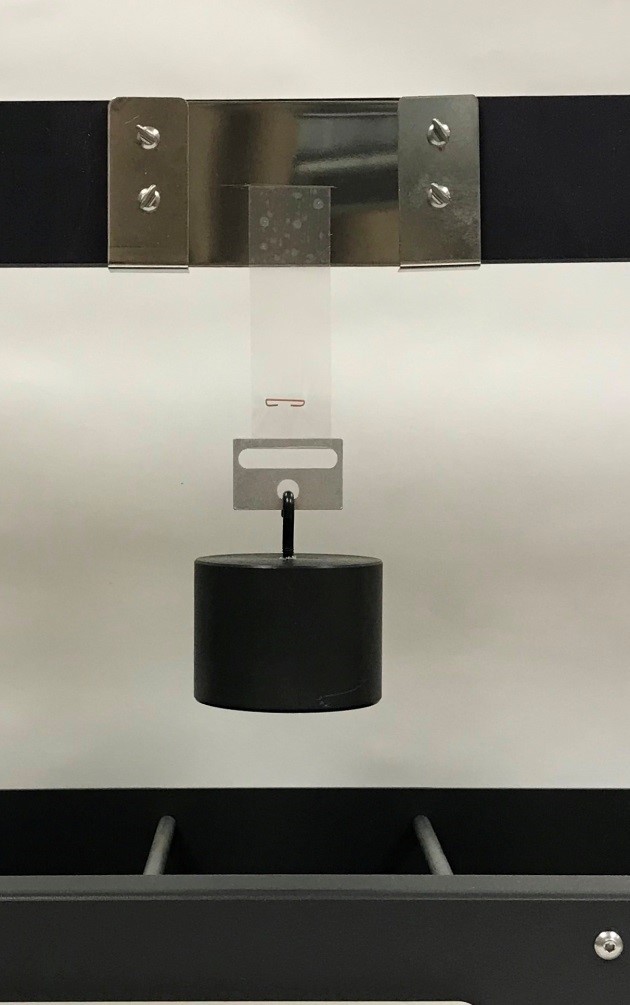

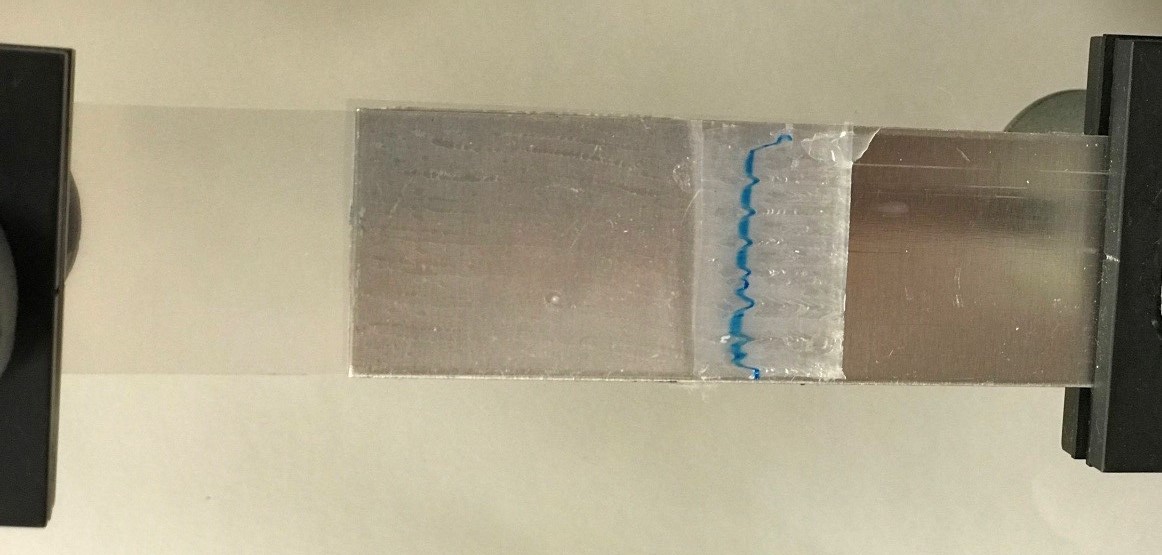

The work of the university's researchers has made possible to overcome these weaknesses and to develop a procedure to obtain a family of adhesives with high tack and good peel strength in specific temperature ranges only, decreasing considerably when these limits are exceeded.

This allows to obtain a smart adhesive that can be adapted to the needs of the client's application, customizing the degree of stickiness and the temperature ranges in which it is active.

The new polyurethanes do not contain solvents and they can be applied on the carrier at moderate temperatures (lower than 120 ºC).

The production process has been carried out satisfactorily at laboratory level where the combination of its components and the synthesis processes have been optimised.

Different adhesives have been developed that operate satisfactorily in various temperature ranges. These adhesives have been characterized and their applicability has been validated in different uses such as biomedical or low temperature conditions.

The following sectors of interest have been identified:

Biomedical Sector

Body temperature conditions are very stable. A number of polyurethane pressure sensitive adhesives have been developed that operate only in these temperature ranges. This has a great applicability for example in the fixation of bandages on the skin. In addition, by slightly varying the temperature, the tack can be eliminated, avoiding patients the usual discomfort of removing the bandages.

Labelling sector

This technology also has great potential in the labelling sector. There are containers and packages in all types of industries and these must be labeled and wrapped for proper treatment.

Sometimes these packages must operate in very specific temperature conditions. This technology makes it possible to define optimum tack in very specific short temperature range, outside of which adhesive tack is considerably reduced. Good label condition can be a good indicator that the package has maintained the preset temperature conditions over time.

It can also be useful for removing labels from products once they have fulfilled their function. By slightly varying the temperature of the label, they are easily detached.

Researchers are looking for partners to negotiate patent licensing agreements, as well as to develop R&D projects to look for new applications for adhesives.

This technology is protected by patent:

• Application number: P201731444

• Application date: 20/12/2017

Molecular Biology and Biotechnology

Footwear and Textile

Construction and Architecture

Pharmacology, Cosmetics and Ophthalmology

Engineering, Robotics and Automation

Toys

Wood and Furniture

Materials and Nanotechnology

Medicine and Health

Stone and Marble

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959