Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group Carbon Materials and Environment which belongs to the Inorganic Chemistry Department and the University Materials Institute of the University of Alicante has developed a new procedure for the preparation of sensors in order to detect gaseous hydrogen in a simple, economical and efficient way. The main advantages of this technology are the robustness, simplicity and reliability of the prepared sensors and it can be used in the following industrial sectors: automotive, energy, gas separation, gas production and fine chemistry. The research group is looking for companies acquiring this invention for: commercial agreement or technical assistance or manufacturing agreement or technical cooperation or a combination of some of these services

Nowadays the use of H2 is one of the most promising alternatives to replace fossil fuels in the energy industry. The present energy perspectives focus on the production of H2 by the electrolysis of water through renewable energy sources and the reforming of hydrocarbons such as ethanol or other organic compounds. However, H2 is a colourless and odourless gas, with high diffusivity, highly flammable at concentrations above 4% vol., and explosive over a wide range of concentrations (15-59 %) at standard atmospheric pressure. Therefore, safety issues concerning its generation, transport, storage and use must always be considered. There is a wide variety of H2 sensors capable of measuring different kinds of signals usually based on materials such as optical fibers or semiconductors. Continuous efforts are being made in order to improve sensitivity, selectivity, response time and reliability, as well as diminishing production costs, size and power consumption of the devices, to meet the demands of a future H2 economy scenario. In this situation, CNTs can be presented as an alternative towards the development of devices designed for the detection of gases including H2. In this sense, the preparation of CNT-based gas sensors has been widely studied and reported in the literature.

For the development of gas sensors, a response of the device is required when in the presence of the analyte gas. Among the requirements that these devices must fulfil in order to find a practical application are delivering a stable signal towards the analyte gas under ambient conditions, showing a reversible behaviour, and performing with high sensitivity, selectivity and low response time for different gas concentrations. CNT-based gas sensors have been developed and proved to perform very well for the detection of several analyte gases, such as NH3, CH4, H2S, O2, NO2 and H2.

We report the preparation of H2 sensors based on Pd nanoparticle-doped CNMs by a very simple, low-cost procedure, using commercial Single Wall Carbon Nanotubes (SWCNTs), Multi Wall Carbon Nanotubes (MWCNTs) or carbon nanofibers (CNFs) as support. The procedure involves the preparation of the CNMs suspension and the metal nanoparticles suspension separately, and the consecutive deposition of the two suspensions onto a substrate to prepare the sensor. This preparation protocol allows perfect control over the different components in the sensor, including the amount of CNMs and the size, shape and amount of metal deposited on them.

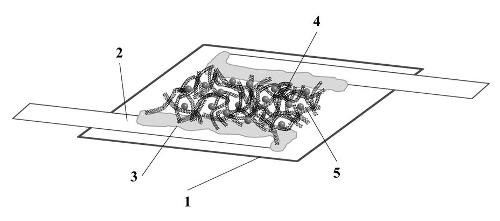

The procedure followed for the preparation of these devices involves:

- Preparation of the non-conductive support. Two adhesive metal strips are placed on each side of the non-conductive support to act as electrical contacts. Conducting paint is applied improve conductivity.

- Preparation of a suspension of carbon nanomaterials in a solvent. The carbon nanotubes may be single-walled (SWCNT), multi-walled (MWCNT), CNFs or any combination of them. The solvents may be organic or aqueous.

- Controlled deposit of the suspension of CNMs on the support and drying.

- Preparation of the nanoparticle suspension, avoiding sintering.

- Controlled deposition of the nanoparticles suspension on the support and drying.

Figure 1. Scheme of a device used for hydrogen detection. (1) Non-conductive support; (2) Adhesive metal tape; (3) Conducting paint; (4) CNM deposit; (5) Metal nanoparticles

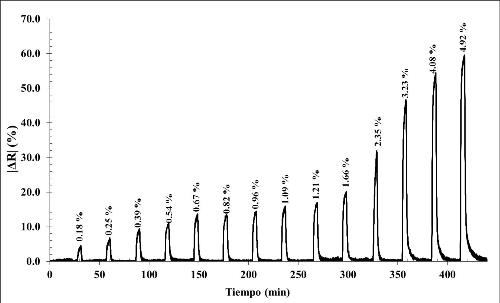

The hydrogen sensors obtained by this procedure have been characterized by standard hydrogen detection tests whose results have proven the efficiency in terms of sensitivity, linearity, reproducibility, and response and recovery times (see Figure 2).

Likewise, the CNM and nanoparticle suspensions are stable which eases their implementation at different levels, including industrial. This is mainly due to the simple nature of the sensor preparation procedure used, based on the use of two independent suspensions which may be stored over long periods of time.

Figure 2. Results on the sensitivity of the sensor towards different hydrogen concentration, as indicated for each pulse

The method employed to prepare this kind of sensors has proven to be very simple to give rise to highly sensitive sensors which perform with very high reproducibility under realistic conditions. The nature of the suspension of the CNMs has a paramount influence over the samples behaviour. As an example, the sensors prepared from the water suspension show an enhanced sensitivity with respect to DMF-based systems, due to the higher degree of dispersion of

the SWCNTs and the characteristics of the nanoparticles/polymer/SWCNT system.

This technology has been developed and tested successfully at laboratory scale. The results of the different tests on the sensors obtained have proven the efficiency of these devices in the detection of gaseous hydrogen in terms of robustness, sensitivity, proportionality between the signal measured and the response of the sensor, reproducibility and short response and recovery times.

The present invention deals with a novel, simple and efficient procedure for the synthesis of devices for the detection of gaseous hydrogen with special interest for the industry related to sensor fabrication and the detection of chemical substances, which moreover presents a low production cost per sensor.

Among other applications, the prepared sensors may be used as safety devices in any industry or application which uses, produces, or stores hydrogen, such as:

• Hydrogen-powered vehicles

• Hydrogen fuelling stations

• Hydrogen generation and storage stations

• Transportation and storage systems (deposits, low and high pressure cylinders, compressors, pipelines, etc.)

• Industrial vehicle battery charging zones

• Electrical power station transformers

• Systems for the analysis and measurement of gases

This technology is protected by patent:

• Title of the patent: "Procedimiento de preparación de dispositivos para la detección de hidrógeno a temperatura ambiente"

• Application number: 201300598

• Application date: 20/06/2013

Engineering, Robotics and Automation

Toys

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959