Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

LICENSED

LICENSED

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The most innovative aspect of this technology is the fact that it uses a mechanical method, rather than a chemical dissolution, to facilitate access to the area between layers of the laminates. As the reactant accesses the interlayer, they eliminate the adhesive that joins these films, thus producing the separation of these. This process of separating layers is called delamination.

Companies interested in the commercial exploitation of this technology are sough.

Sometimes, a single type of plastic alone is not capable of reaching the characteristics demanded by the industry. Still, it is necessary to use a combination of plastics glued together to form a multilayer composite material (laminated plastic). Thus, for example, with the combination of two plastics with different barrier properties for oxygen and water, a composite plastic can be obtained that protects from oxygen and water.

Another use of laminates is as barrier for printing pigments. When someone is working with food packaging, it is essential to ensure that the ink does not come into contact with the food. In this case, printing is done first at one of the plastic sheets, and a layer of the same plastic is added over to protect the food from the ink.

Although laminated materials have many technical advantages, they suppose a significant problem when it comes to recycling due to the differences in melting points between the polymeric materials that make them up, restraining them from being reprocessed by extrusion. Therefore, before the extrusion step, it is necessary to delaminate and separate the different polymers that form the laminated material.

The traditional methods used for delamination are based on selective dissolution, in which each layer is solved using organic solvents. These solvents present environmental and safety problems since they are toxic and flammable. On the other hand, because of the price of the chemicals, these methods are not feasible for most laminated materials.

There is a need for a procedure to delaminate, which is efficient for most laminated plastics, so that allows the recycling of each of the plastic materials that compose them.

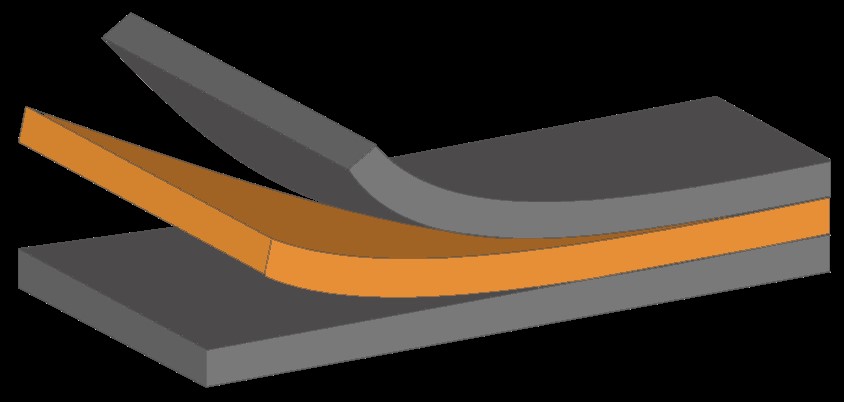

The research group, 'Engineering for Circular Economy (E4CE)' of the University of Alicante, has developed a procedure for removing the adhesive that holds the laminated plastic sheets (Figure 1) together, and the subsequent removal of the ink. This procedure facilitates the recycling of each of the plastic materials in the composite material.

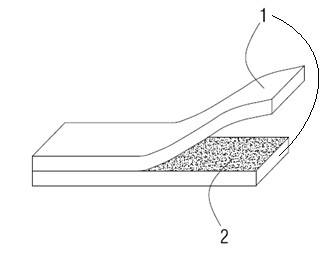

Figure 1. General diagram of a laminated plastic material, comprising at least two layers of plastic material (1), and an interlaminar zone (2) between the two layers of plastic material (1).

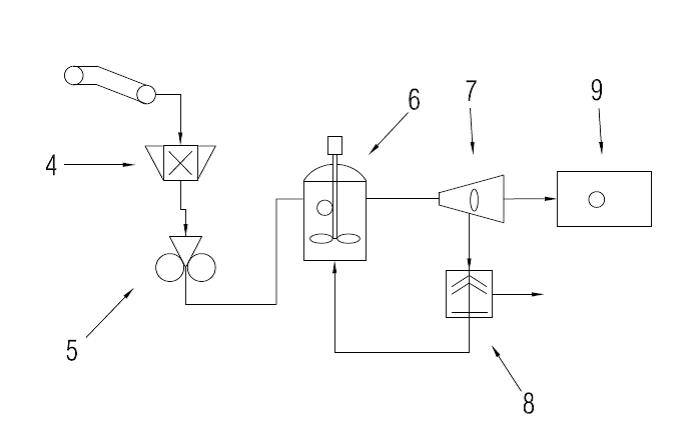

This procedure consists of the following steps (Figure 2):

1. Conditioning and crushing of the laminated plastic material previous treatment (optional).

2. Micro-perforation of the laminated plastic material.

3. Removal of any ink or adhesive.

4. Separation of water from the plastic material.

5. Removing of any ink or adhesive from water.

6. Separation of plastic materials.

Figure 2. General diagram of the stages for the elimination of adhesives and/or interlaminar inks in laminated plastic. 4. mill; 5. microperforation device; 6. stirring reactor; 7. centrifuge; 8. clarifying centrifuge; and, 9. decanter.

The laminated plastic material can be presented in different forms: leftover rolls from the packaging industry or used packs form the yellow container or the mixed bin. All this material will be selected, removing large impurities and place on a conveyor belt. The laminated plastic material could be ground in a specific mill for the plastic film to pieces between 5 and 20 cm to improve the procedure.

In step 2, the micro-perforation of the laminated plastic material will be carried out using micro-needles in a micro-perforation device. The device comprising at least a pair of double rollers configured, so they rotate in opposite directions. The crushed laminated plastic material coming from the mill falls into the hopper and, due to its weight, is forced to pass between the rollers, where the micro-needles produce perforations in the material that allows the reagent to access the interlaminar area.

The micro-perforated laminated plastic material is introduced into a reactor so that chemical agents can access the interlaminar zone of the laminated plastic material and remove the ink and adhesive.

After the washing stage, the plastic material with the washing solution is introduced into a centrifuge to separate the plastic material from the aqueous solution, which contains the water together with the ink and adhesive residues. Besides, to separating plastics which form multilayer, the high shear forces produced in the centrifuge promote the separation of the films and thus the removal of adhesive.

For complete recycling of all the materials, the water treatment stage is carried out in a clarifying centrifuge, adding flocculants and coagulants before the centrifugation to help clean the water. In this way, the adhesive particles are separated as sludge and, the water is recycled to the main reactor.

Finally, the last step is necessary to finish delaminated plastic material recycling. In the case that the initial laminated plastic material is made with sheets of different plastics, it must be separated before processing by extrusion. This separation could be done by wet-phase decantation based on the difference in density between the various plastics, through the use of hydrocyclons or any other separation technique available on the market.

This technology has the following advantages:

• It allows the vast majority of multilayer plastics to be recycled.

• It allows eliminating the printed ink present in the interlayer.

• The technology is simple and easy to implement.

• Environmentally friendly procedure.

• No need to use organic solvents.

• It is not necessary to cut material below 5x5 cm2.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

The removal of any ink and adhesives from laminated materials is very complex, as the plastic itself prevents access to the reagent. The principal innovative aspect of this technology is the fact that micro-perforations are made in the laminated plastic material, which allows the access of reagents to the interlaminate area. In this way, ink and adhesive can be removed at later stages

For its commercialization, it would be necessary to build a demonstration plant that processes 500 kg/h, which will allow validating the technology, as well as the products obtained.

This procedure could be useful in the packaging and plastic recycling sectors

• Patent license agreements.

• Technical cooperation agreements (R&D projects) for the use of the technology or application in other waste or sectors.

• Partners for establishing a technology-based company for multi-layer plastic recycling through this technology.

Company profiles sought:

• Recycling of plastic waste.

• Manufacturers of plastic containers.

• Producers of virgin raw material.

This technology is protected by patent application:

• Title of the patent: "Procedure for the removal of adhesives and/or interlaminar inks from the laminated plastic material."

• Application number: P201930975.

• Application date: November 7, 2019.

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959