Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The "Advanced Materials" research group at the University of Alicante has developed a foamed material comprising three phases: a structural matrix, at least one host phase, and a fluid. This material is characterized by the fact that the structural matrix comprises a plurality of interconnected porous cavities, the host phase(s) is/are housed within at least one porous cavity of the structural matrix and the fluid is housed within the porous cavities. The host phase(s) can be housed within the porous cavities of the structural matrix without maintaining any union or maintaining discrete unions with the latter.

The structural matrix may consist of a material of a metallic, polymeric, ceramic nature or mixtures thereof. Meanwhile, the host phase(s) is/are a functional material, the fluid being a liquid or a gas.

These materials have many potential uses, among which ones is as an implant material, with the additional possibility of exerting a controlled release of drugs.

Companies interested in commercial exploitation of this material through a patent license agreement are sought.

Interconnected pore foamed materials have been known for a long time. In this sense, many methods have been developed for the manufacture of foamed materials from metals, ceramics and polymers.

Of all the methods developed, the one that allows the best control of the obtained material is the method of infiltration of martyr preforms or also known as replication method. This method offers materials with multiple advantages, since the pores of the foamed material have the characteristics of size, size distribution and shape of the particles or fibers of the original preform constituted by the sacrificial material.

Foams manufactured by replication have a wide spectrum of applications, given the fact that they can be designed according to specific needs, recently postulated for use in medical applications of implantology, since it is potentially possible to grow living tissue inside the cavities and thus reduce the risk of entrapment that can occur when using a mass implant. However, the properties of conventional foams manufactured by replication are exclusively a function of the material they are made of and their porous characteristics. There is therefore a need to develop new foamed materials of simple manufacture and with improved properties whose functionality is not limited by the material of which the foamed material is made, as well as by the size, shape and size distribution of their pores.

The research group "Advanced Materials" of the University of Alicante has developed a foamed material with application in implantology that comprises a structural matrix, at least one host phase and a fluid.

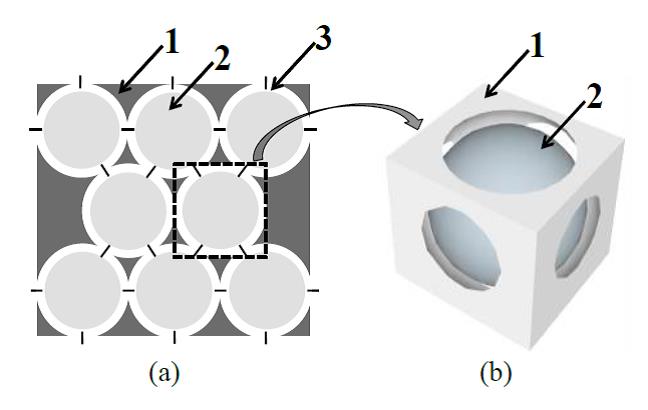

This foamed material is characterized because the structural matrix comprises a plurality of interconnected porous cavities, the host phase is housed inside at least one porous cavity of the structural matrix and the fluid is housed inside the porous cavity (Figure 1).

The host phase, in finely divided particle or fibre form, is housed within the porous cavity of the structural matrix, and can be:

• without maintaining any bond with it: between the walls of the porous cavity of the foamed material and the surface of the host phase there is a gauge of space that is occupied by the fluid.

• maintaining union with this structural matrix: between the walls of the porous cavity of the foamed material and most of the surface of the host phase there is a space gauge that is occupied by the fluid.

The structural matrix of the foamed material may consist of a material of a metallic, ceramic or polymer nature or mixtures thereof.

The host phase of the foamed material, preferably in a finely divided state (particles or fibres), is a functional material, i.e. any material that confers a certain function, such as, for example, an adsorbent function. These include: carbon, active carbon, organo-metallic skeleton materials (MOFs), etc. The foamed material can be made up of several host phases of a different nature, so that each of them provides a different functionality to the final foamed material.

The fluid inside the porous cavity of the foamed material can be a gas or a liquid. This fluid is found surrounding all or a large part of the host phase(s) in the porous cavity, in such a way that the fluid can circulate through the interior of the foamed material, as it has interconnected porosity, and renew itself if a pressure gradient is imposed at its ends.

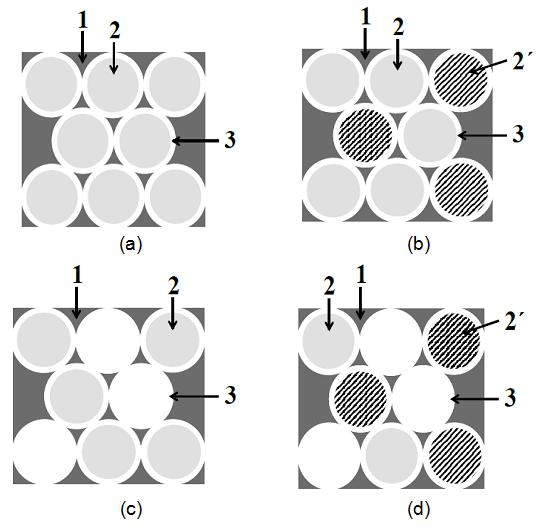

The host phase(s) of the foamed material can be housed in all or part of the porous cavities, leaving the host phase free and the rest of the cavities completely occupied by the fluid (Figure 2).

• If the structural matrix and the host phase(s) are not joined, both fulfil their functionality independently.

• The matrix phase can be of a material that has good mechanical properties, so that it can withstand mechanical stresses derived from implantology use.

• The host phase(s) can be a material with varied mechanical properties and with a high specific surface area (functional material), so that the material as a whole has a higher surface area and can serve as an adsorbent of chemical substances.

• Low density (great reduction in the weight of the prosthesis compared to mass titanium prostheses).

• Absence of toxic metal elements.

• Bioabsorbable material (the material of the matrix phase is pure magnesium, which can be slowly dissolved in the organism by means of its special surface treatment).

• Controlled local drug release (the host phase has the ability to adsorb drugs that can be slowly released locally into the body to prevent infection or perform hormonal treatments).

The present invention falls within the field of foamed materials and in particular refers to an interconnected pore foamed material containing within its porous cavities at least one host phase, which gives specific functionalities to the foamed material.

This material is especially useful as an implant material. The material acts as an implant allowing the growth of living tissue in its interior with the adsorbent host(s), in such a way that it retains at least one substance with pharmacological activity in a living organism, so that this substance is released in a controlled way by desorption from the host phase in the living organism.

In addition to this use, foamed material may also be used:

• For the controlled release of chemicals or pharmaceuticals.

• For the adsorption of gases, liquids or dissolved solids.

• As a catalyst.

• As a filter for inorganic or biological substances.

• As a magnetic material.

• As impact absorbing material in passive safety parts of land, air and sea transport vehicles.

• As an electrode material, particularly as an electrode for electrochemical conversion in chemical synthesis or decontamination processes of water and/or air.

• As an absorber of electromagnetic radiation for its transformation into heat or electrical energy.

• As radar wave resonator material, applied in radar invisibility technologies.

• As a template material for crystalline growth in the gap between the structural matrix and the host phase(s).

The research group is looking for companies in the field of implantology interested in acquiring this technology for commercial exploitation through:

• Patent licensing agreements to transfer the rights of use, manufacture or marketing of the technology to third parties.

• R&D project agreements (technical cooperation) for the development of new applications, adapting the technology to the specific needs of the company, etc.

• Subcontracting agreements for technical assistance, training, etc.

This technology is protected by patent.

- Title of the patent: "Foamed materials of pore interconnected with host phases, procedure for the preparation of such materials and uses thereof".

- Application number: P201730890

- Application date: 05 - 07 - 2017

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959