Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Adhesion and Adhesives Laboratory of the University of Alicante has developed a new method (equipment and process) to determine the degree of self-repair and to monitor the kinetics of self-repair of polymeric materials. The new method also makes it possible to follow the self-repair process of composites, ceramic materials, materials based on cement, mortar or concrete, and textile materials.

This invention stands out for being a simple, fast and reproducible method, and allows several in situ measurements to be carried out on the same sample at different temperatures and with different geometry and size of the materials.

The group is looking for companies or institutions interested in acquiring this technology for commercial exploitation.

Inspired by living tissues, research on materials with the ability to self-repair has advanced significantly in recent years due to their potential in different fields of technology. This area of research could significantly extend the lifetime and safety of components of different materials in a wide range of applications. The emerging new class of "self-repairing materials" may allow the reconstruction of the molecular structure from fractured to intact form. However, most known self-repair processes require the application of external stimuli (heat, radiation or chemical reactions, among others), which is a limiting aspect in some applications.

So far, there is no method in the literature to quantify the degree of self-repair and/or to monitor the kinetics of self-repair in materials. Currently existing procedures are very laborious, are not reproducible and use an indirect measure of the material property, such as its mechanical tensile and/or breaking strength, viscoelastic properties or conductivity, in order to assess the self-healing efficiency.

Therefore, it is necessary to establish a simple, reproducible, repeatable, and efficient method to quantify and follow the kinetics of self-repair in materials.

This is a new method (equipment and process) that allows determining in situ the self-repair of materials, as well as quantifying the efficiency of the self-repair and monitoring the kinetics of the self-repair process.

This invention would be applicable to polymeric materials, composites, ceramic materials, materials based on cement, mortar or concrete, and textile materials.

The method consists of perforating the material by allowing a stream of inert gas to flow through the perforated hole, so that the decrease in gas flow through the perforation is directly related to the kinetics of the self-repair process. When the gas flow is interrupted, the self-healing process is complete.

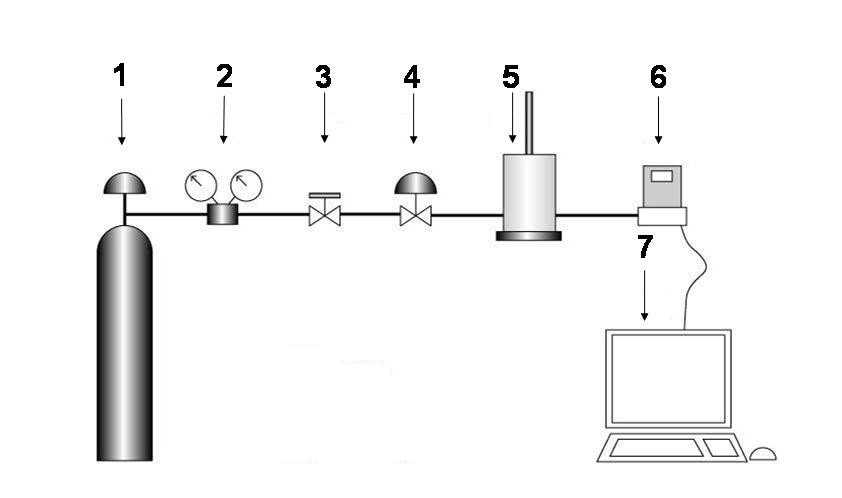

The system (see Figure 1) consists of an inert gas bullet, a pressure regulator, a gas flow shut-off and control valve, the self-repair measurement equipment, a flow meter and data acquisition equipment. In addition, the self-repair equipment contains a gas inlet and outlet and a stem with the piercing element.

Figure 1: Schematic of the material self-repair measurement equipment: 1- Gas bullet; 2- Pressure regulator; 3- Shut-off valve; 4- Gas flow control valve; 5- Main body; 6- Flow meter; 7-Data acquisition device.

As for the process followed to quantify the self-repair, this consists of placing a piece of material in the self-repair equipment, hermetically sealing it. A constant flow of inert gas is passed through for the duration of the measurement process. The sample is pierced with the shank oriented piercing tool (as many times as necessary). The stem is removed from the sample, the gas flow and the time it takes for the gas to stop passing through the sample is measured, at which point self-repair is considered to have occurred.

MAIN ADVANTAGES OF THE TECHNOLOGY

The main advantages of this technology are as follows:

• Simple method

• Fast method

• Efficient method

• Reproducible method

• It does not require the application of external stimuli (heat, radiation or chemical reactions).

• Several in situ measurements can be performed on the same sample.

• The sample can be of any geometry and with a very wide range of dimensions and thickness.

• The sample can be heated to temperatures above room temperature.

• The stem and piercing element allow 360° rotation.

• The gas flow output of the main body of the self-repair measuring equipment is continuously monitored by a flow sensor.

INNOVATIVE ASPECTS

This is the first method and measuring equipment that allows direct measurement of the degree of self-repair and/or monitoring of the kinetics of self-repair in materials. This invention represents a breakthrough in the development and implementation of this type of materials, with multiple applications, in society.

A prototype has now been successfully developed by the Adhesion and Adhesives Laboratory.

It can be used in all fields where self-healing materials are used, e.g. in the medical field, biomaterials, cosmetics, textiles, technology, coatings, adhesives, sealants or space.

Companies interested in acquiring this technology for commercial exploitation through patent licensing agreements are sought.

This technology is protected by patent application:

• Patent title: “Equipo de medida de la autorreparación in-situ de un material y método de medida”

• Application number: P202330118

• Application date: 16/02/2023

Construction and Architecture

Pharmacology, Cosmetics and Ophthalmology

Materials and Nanotechnology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959