Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The technology is environmentally friendly and the method is rapid and selective with yields higher than 70%. These novel compounds can be customized for any industry application with potential interest. The group is looking for companies interested in acquiring this technology for commercial exploitation through licensing agreements of the patent, manufacturing agreements or research agreements to develop new applications.

Natural dyes and pigments have been used since antiquity as coloring agents. However, synthetic dyes show greater stability, allowing new applications and entering new markets in such varied fields as biology, chemistry, histology, cytology, medicine, microscopy, textils, optics, electronics, plastics, adhesives, storage devices, photographic equipment, etc.

In this sense, dyes derived from indolizines found interesting applications in recording devices and laser scanning, thermography, photothermography, electrochromic devices, optical filters and photoelectric converters (e.g., solar cells). The great interest about indolizine dyes was manifested through Intellectual Property Rights of Japanese companies such as Fuji Photo Film, TDK Corporation and Sony Corporation.

Indolizine dyes (T) are normally obtained through divergent multistep synthetic sequences (e.g., two steps: A + B → C, C + D → T), or through convergent synthesis using two different compounds (C and F), previously synthesized in one or more steps (A + B → C, D + E → F), which are then assembled to obtain desired product in one step (C + F → T).

In order to overcome limitations described above, it has been explored synthesis of novel indolizine dyes and succeeded in developing a novel efficient synthetic route.

This invention relates to a new family of indolizines with dye properties and its production involves the use of a single starting material. This is an indolizine which is transformed into another more substituted indolizine with dye properties, under mild reaction conditions (room temperature and atmospheric pressure)

The main innovation of this method of synthesis is that the new substituent that binds to the indolizine nucleus is derived from another molecule of the starting indolizine (A + A → T), and it is selectively incorporated into a specific position in the molecule.

Therefore, the present invention relates to a new indolizine with solvatochromic properties and a novel, selective and effective synthetic procedure of these dyes from simpler indolizines.

Alternatively, the indolizine dyes can be obtained through multicomponent synthesis (from commercially available materials) of the precursor indolizine of the dye in a single reaction vessel. In this case, the isolation and purification of the dye precursor indolizine is unnecessary, showing a similar yield but with a decrease in the cost and time of production.

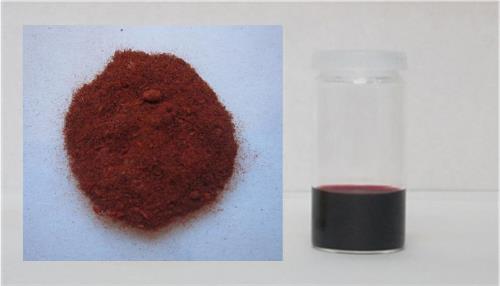

The synthetic process is very simple (it is produced in a single reaction vessel) and the dyes obtained are orange-red solids:

Figure 1: Dye in the solid state and in solution.

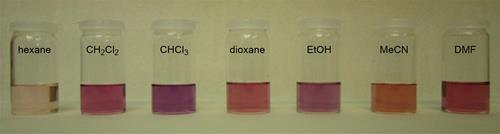

In addition, this new class of compounds has the interesting and advantageous property of being solvatochromic, that is, its color depends on the solvent used, with the potential applications that can appear. This feature is due to the chromophore group which is selectively inserted at the 7-position of the starting indolizine (which comes from another indolizine homologous), providing a high conjugation and, therefore, solvatochromic dye properties.

Thus, a different dye color can be obtained according to the solvent used for dissolving the solid indolizine (hexane, dichloromethane, chloroform, 1,4-dioxane, ethanol, acetonitrile and N,N-dimethylformamide):

• The indolizine dyes are obtained in one step from commercially available materials, unlike current procedures, which involve multiple steps. This is an advantage in the production process, as it reduces costs, increases the final yield and less waste is generated.

• The procedure is based on a very simple treatment which produces indolizine dyes in yields higher than 70%.

• The present invention does not require the use of inert atmosphere, dry solvents or physical activation (heat or radiation) to obtain the final product.

• Unlike other methodologies for preparing indolizine dyes (requiring temperatures around 100°C), this process is carried out at room temperature and atmospheric pressure, which simplifies the method and decreases production costs.

• This is an environmentally friendly technology because it does not use solvents such as dioxane, pyridine, chloroform or benzene, which are used in other methods and are characterized by their high toxicity and demonstrated carcinogenicity.

• The selectivity of the reaction is very high. The indolizine dye is obtained with absolute control, obtaining a single isomer of the ten possible.

In addition, the research group has a pilot plant that is certified to work under GMPs (Good Manufacturing Practices), where scaling is possible to provide multi-kilogram quantities.

Figure 3: Pilot plant

For example:

Or even may allow discovery new applications. It is also possible to introduce in the molecule different functional groups in order to adapt it to the industrial sector of interest to get a specific application: for chemicals and materials (plastic industry, homogeneous injections/extrusions, non-homogeneous injections/extrusions, polymer (plastics) materials), textile (synthetic and natural), leather tanning, paints, cosmetics, scanning related, alternative energy (solar energy and photovoltaic solar), and electronic chemicals.

Toys

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959