Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group Polymer processing and pyrolysis of the University of Alicante has developed a novel photobioreactor in order to grow massively different species of microalgae, even on industrial scale and with automation.

The main advantages of this technology are: high productivity, better CO2 consumption, better light transfer to the culture, more effective shaking and less cleaning and maintenance time. It can be used in the following industrial sectors: biofuels, aquaculture, food, pharmaceutical, cosmetics, etc.

The research group is looking for companies acquiring this technology for licensing agreement and technical cooperation.

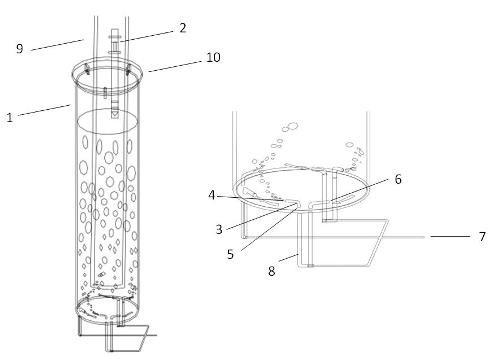

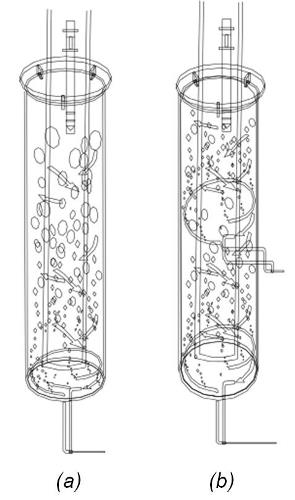

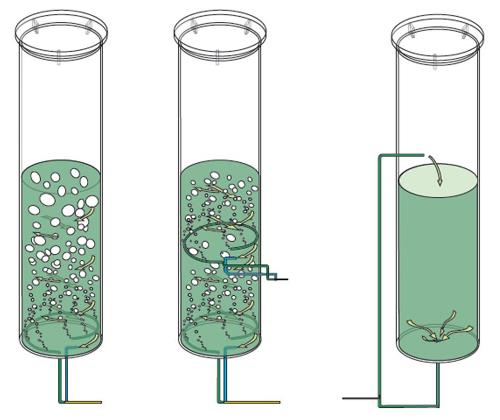

-Air-lift type with internal recirculation concentric tubes (the main drawback is that the swirl formed by the bubbles is smaller than the diameter of the photobioreactor, so that the walls thereof are coated with adhered microalgae, preventing thus an optimal light transfer).

-Submersible reactor, enabling economic control of the culture temperature (the main problem is the structure cost and complexity of use. In addition, it must be controlled gases as oxygen, which is accumulated because the container is leakproof).

Technology Description

Figure 2:

Moreover, the main advantages of this technology are:

• High productivity.

• The stirring is more effective because the effects of both types of reactor (bubble column and air-lift type) are added, which allows a faster microalgae exchange between areas of light and dark.

• Better light transfer to the culture because the bubbles generated directly mix the culture resulting in an expansion thereof.

• Maintenance of the uniformity in the distribution of gas in the system.

• Improves nutrient solution: the way in which is injected CO2 to maintain the pH of the culture allows that the residence time of CO2 in the medium increases, thus making better use of it (the whole culture must be crossed to reach the surface).

• Better control of the culture conditions (pH, temperature, etc.).

• There is a lower adhesion of microalgae on the photobioreactor walls, which achieves a greater use of light when the culture reaches high concentrations, and it barely requires cleaning and maintenance.

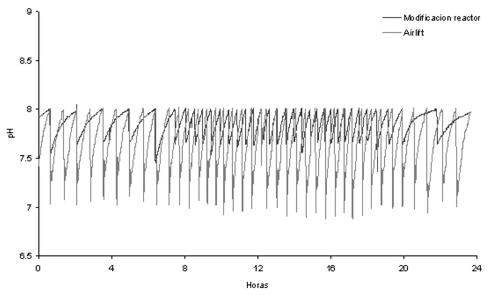

• CO2 consumption to reach a suitable microalgae growth is significantly reduced compared with other systems. The best use of this nutrient compared to the conventional air-lift reactor is due to the higher residence time of CO2 it is in the culture: there is a higher concentration dissolved and therefore higher availability for microalgae. Figure 3 shows how the number of CO2 injections performed in a culture of Nannochloropsis oculata in a given time interval is reduced with respect to a reactor of conventional air-lift type:

• Due to its configuration, it allows easy scaling on industrial level.

• It is robust and easy to install and operate (technical experience is not required for its management).

• The better use of sunlight minimizes energy consumption and cost.

• It is able to be automated (it has aeration, circulation, feeding and harvesting circuits).

• It is thermostated for optimum growth of microalgae.

• It has an automatic pH probe for CO2 injection.

• It allows to cultivate some microalgae species, such as: Chlorella, Nannochloropsis oculata, Nannochloropsis gaditana, Isochrysis aff. Galbana, Spirulina platensis, Dunaliella salina, Odontella aurita, Phaedactylum tricornutum, Porphyridium cruentum, etc.

• The culture conditions have been optimized for Nannochloropsis oculata, a kind of microalgae particularly resistant to pollution (fungi, yeasts, bacteria, viruses, etc.).

The research group has developed a prototype that is available for experimental demonstration. The photobioreactor has a work volume of 30 litres and its average productivity is 6 g/day.

Furthermore, the research group has a pilot plant for carrying out the pre-industrial scaling with reactors of 500 litres (with a production capacity of 100 g/day). There are also available sea water tanks, decantation tanks, filtration, lyophilization and molecular characterization equipment, and culture conditions can be optimized for some microalgae species.

Microalgae have high photosynthetic efficiency, so their growth is faster than plants. In this sense, microalgae are a very interesting material for the generation of biofuels.

Addition of biomass to produce biofuels, microalgae can be used to obtain other valuable substances on different industry sectors: food, pharmaceuticals, cosmetics, nutraceuticals, etc.

Depending on the species cultured, it can be obtained:

Antibiotics

Enzymes

Proteins

Peptides

Pigments

Vitamins

Biopolymers

Polysaccharides

Polyunsaturated fatty acids

Triglycerides

Essential lipids

Oxylipins

Antioxidants

Etc.

• Licensing agreement.

• Technical cooperation to test new applications (biofuels, cosmetics, pharmaceuticals, nutraceuticals, food, etc.) and to adapt it to microalgae species, such as: Chlorella, Nannochloropsis oculata, Nannochloropsis gaditana, Isochrysis aff. Galbana, Spirulina platensis, Dunaliella salina, Odontella aurita, Phaedactylum tricornutum, Porphyridium cruentum, etc.

• Application number: P201200903.

• Application date: 19th September 2012.

Biology

Molecular Biology and Biotechnology

Pharmacology, Cosmetics and Ophthalmology

Engineering, Robotics and Automation

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959