Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Laboratory of Adhesion and Adhesives of the University of Alicante and the company Dental Global Training, have developed a new procedure to incorporate efficiently graphene derivatives (nanofibers, nanosheets, nanoparticles) in chemically cured resins by using an in situ polymerization technique. The method is very simple and fast, it provides an excellent dispersion of the graphene derivatives in both the solid components of the resin and in the cured polymer matrix, and is entirely friendly with the environment. The novel method does not require the use of organic solvents nor water, ultrasounds, and high pressure/temperature.

The resulting resin composites show excellent mechanical properties, good wear resistance, easy manipulation and increase the insolubility in oral fluids, and therefor they have special interest in applications in odontology, traumatology and non-medical applications too (automobile, construction, civil engineering, aeronautics, space engineering, electronics and optics). It is looking for companies interested in acquiring this technology for its commercial exploitation.

The acrylic resins are commonly used for medical, odontological and several industrial applications because of their excellent optical and mechanical properties, adequate processability and good biocompatibility.

The acrylic resins polymerize in presence of free radical initiators. The initiator may be activated physically (temperature – thermal polymerizable resins -, irradiation with visible light - photopolymerizable resins) or chemically (tertiary amines, sulfinic acids - autopolymerizable resins).

The acrylic resins for dental applications consist usually in two components (one solid or polymer, and one liquid or monomer), that should be mixed for polymerization. The solid component consists of spheres of a polymer or a copolymer and an initiator, and may contain opacifying pigments, plasticizers, fibers and adhesion promoter. The liquid component contains commonly methyl methacrylate (in autopolymerizable resins) with one inhibitor and one activator, or urethane dimethacrylate (in photopolymerizable resins) with one inhibitor and one photoinitiator, and it may contain plasticizers and adhesion promoter. The acrylic resins are prepared by mixing both components (1:2 ratio of monomer to polymer), and the mixture has a certain gel time after which the chemical reaction of polymerization is produced.

The acrylic polymers have two main drawbacks, the limited mechanical properties leading to the appearance of cracks and its propagation, and the shrinkage caused during the polymerization. We have proposed the incorporation of graphene derivatives (nanoparticles, nanofibers, nanosheets) to the acrylic resins for reducing or avoiding those limitations. However, for being effective, an adequate and good dispersion of the nanoparticles in the solid acrylic polymer matrix is mandatory.

Several methods have been described in the scientific literature for achieving a good dispersion of the graphene derivatives into acrylic polymers, including the following ones:

1. Solution mixing: it is adequate but to achieve a good dispersion in a solvent the functionalization of the graphene derivatives is necessary, and furthermore, even though carry out numerous drying phases, the polymer contain residual solvent.

2. Melt mixing: it does not require the addition of solvents, but the extent of dispersion achieved by the graphene derivatives is limited, and therefore the use of aggressive methods of homogenization is necessary, thus promoting the deterioration of the nanoparticles.

3. In situ polymerization: it consists in dispersing the graphene derivatives in the liquid component of the acrylic resin, adding later the initiator and the solid polymer, followed by polymerization under heat or irradiation.

The process of incorporation of graphene derivatives in acrylic resins is not optimal. The current methods are complex and require the use of organic solvents or water, which give poor dispersion of the graphene derivatives in the polymeric matrix; furthermore, those methods require the use of ultrasounds, heat and/or forced evaporation of the solvent.

To overcome those limitations, the research group has developed a new procedure to prepare polymerizable resins with graphene derivatives (nanosheets, nanofibers) that it is fast and it does not require organic solvents, water, ultrasounds, high temperature nor long time.

The procedure consists of three following consecutive stages:

1. Mix the graphene derivatives (nanosheets, nanofibers) with the solid component of the acrylic resin and homogenize the mixture in double orbital centrifuge.

2. Add the liquid component to the mixture of graphene derivatives and the solid component of the acrylic resin.

3. Polymerize the mixture at room temperature and under atmospheric pressure, or by applying slight pressure and moderate temperature.

The polymerizable resins are two- one-component systems conatining a liquid or semi solid consistency. Some examples of those resins are acrylic resins, epoxy, unsaturated polyester, vinyl ester, polyurethane, polyimide, cyanoacrylate, polybenzimidazole, polyarylsulfone, polyphenylene quinoxide and siloxane derivatives.

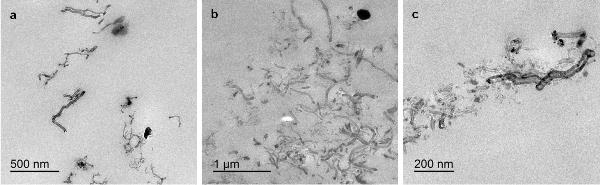

The addition of up to 1wt% of graphene nanofibers allows to obtain a good dispersion in the acrylic matrix.

Transmission Electron Microscopy (TEM) micrographs of an acrylic resin containing different amounts of graphene nanofibres: a) 0.1wt%; b) 0.5wt%, and c) 1wt%.

The addition of a small amount of graphene derivatives produce a considerable increase in the mechanical properties of the polymern (increased elastic modulus and toughness).

Furthermore, the polymerizable resins prepared following this procedure show good homogenity, absense of bubbles, and contain reduced amounts of residual monomer.

MAIN ADVANTAGES OF THE TECHNOLOGY

The efficient incorporation of the graphene derivatives into acrylic resins is not optimized yet, and the actual methods are complex and present some limitations. The new method proposed allows an effective dispersion of the graphene derivatives into polymer matrices by using a modified in situ polymerization process that:

• Does not require organic solvents or water (only solids are involved).

• Does not require the dispersions with ultrasounds.

• It can be carried out under mild conditions (room temperature and atmospheric pressure), or under high pressure (up to 2 bars) and temperature (up to 65ºC).

• The procedure is quick (it requires less than 1 hour).

INNOVATIVE ASPECTS

A new in situ polymerization procedure very simple and quick that allows obtain, under mild reaction conditions and without using solvent, a good dispersion of graphene derivatives in chemically cured polymer matrices.

The technology has been developed at laboratory scale. The experiments and tests made confirm reliability, robustness, and reproducibility of the new procedure.

The present invention can be applied to materials science and chemistry fields. The graphene filled acrylic resins can be used in the following main fields:

1. Odontology: in the manufacturing of a great variety of dental prosthesis (denture base, provisional prosthesis, prosthesis supporting over implants, etc) due to their insolubility in oral fluids, easy manipulation, low wear resistance, and low cost. The graphene filled acrylic resins also inhibit the polymerization shrinkage, imparts toughness and minimizes the appearance of cracks.

2. Medicine: bone cement for Traumatology.

3. Thermoset adhesives and sealants used in the following fields:

• Automobile.

• Construction.

• Civil engineering.

• Space engineering.

• Aeronautics.

• Electronics.

• Optics.

• Others…

It is looking for companies interested in acquiring this invention for their commercial exploitation through:

• License agreement of the patent.

• In search for financial opportunities to develop new applications, adapt them to specific needs of the company, etc.

• Agreements for technology and knowledge transference.

• Technical reports and scientific assessment.

• Specific training depending on the companies needs.

• Standardization services, calibration, national and international technical rules, etc.

• Technological support on those technologies that require high preparation or sophisticated instruments that are not in the companies grasp.

• Staff exchange for specific periods of time (to learn specific techniques).

• Renting of the internal equipment to clients that wish to continue their own tests (the infrastructure of the Department of Inorganic Chemistry – Adhesion and Adhesives Laboratory - or the Technical Services of Research of the University of Alicante (SSTTI)).

The present invention is protected by granted patent:

• Title: “Procedimiento para la preparación de resinas polimerizables con derivados de grafeno”.

• Application number: P201530933.

• Application date: 29th June 2015.

Toys

Materials and Nanotechnology

Medicine and Health

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959