Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

LICENSED

LICENSED

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Researchers at the University of Alicante, in collaboration with Corrientes del Sur SL, have developed a biocompatible device that controls the noise and vibrations of incubators and other equipment used to handle and/or process biological samples.

This device reduces the mechanical stress caused by noise and vibrations on cells, improving survival and increasing cell proliferation. It also improves sensitivity in cell and molecular dynamics assays, and by reducing the variability associated with laboratory equipment, the reliability and reproducibility of experiments are increased in a convenient, rapid, and safe manner.

Companies interested in acquiring this technology for commercial exploitation are being sought.

Noise is a constant presence in all aspects of modern life. Currently, there is a widespread consensus among the scientific community about the negative impact that continuous exposure to noise has on people's physical and mental health, since noise, due to its mechanical wave nature, exerts a direct influence on fundamental processes at the cellular level.

Mechanobiology is an emerging scientific discipline that studies cellular processes in response to various mechanical stimuli, including audible acoustic waves. In this sense, the processes promoted by acoustic waves play a crucial role in the regulation of cellular homeostasis, being crucial in aspects as relevant as wound healing, neurodegenerative diseases, and cancer. Several studies in this field demonstrate the influence of noise on cellular dynamics.

Cell culture incubators are essential pieces of equipment in biological laboratories that maintain optimal conditions for cell growth. These devices employ electromechanical actuators, ventilation systems, valves, and compressors that generate vibrations and audible acoustic noise that can interfere with the reliability of the results obtained.

Therefore, regulatory systems affect the samples, but they depend on the equipment used. This affects the reproducibility of results, as each laboratory has different equipment and even different ways of maintaining test conditions.

Currently, there is no device on the market that protects cell samples from the noise generated by incubators and other devices, leaving the cultures exposed to its effects.

In order to solve the problems described above, a biocompatible device has been developed that allows noise and vibration control in incubators and equipment for handling and/or processing biological samples.

The procedure consists of the usual steps of seeding, incubation, experimentation, and/or sample processing, and also includes a step of inserting a container with the samples into a biocompatible vibroacoustic monitoring device. Therefore, sample incubation is performed within the developed device .

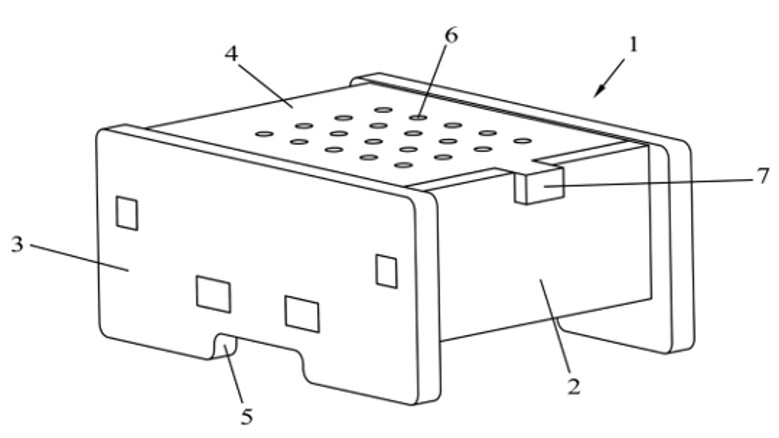

This device (see Figures 1 and 2) consists of:

• A container with an inner base for samples.

• A means of access to the interior of the container.

• Support means on the inner surface of the incubator.

• Some means of environmental regulation.

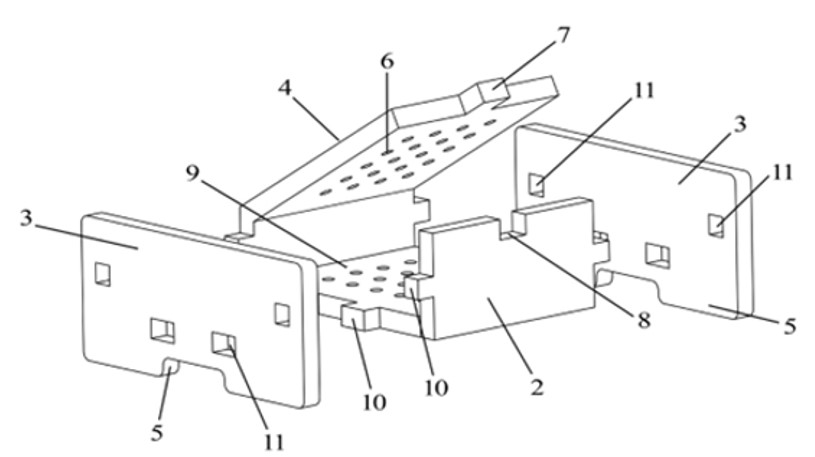

The container preferably consists of a rectangular base to optimize space in the equipment, a main body with a general U-shape, and two side plates, leaving an opening at the top where a lid or top access device can be placed. The main body and side plates can be assembled using tabs that fit into slots.

The upper access means has a handle that fits into a locking groove that retains it by friction. The interior of the container has a base for placing the samples. The lid and base have perforations to communicate the contents of the device with the outside environment, which promotes both thermodynamic equilibrium and gas exchange between the device object of the invention and the incubator. The base is separated from the support surface by legs or support means that decouple the base from the vibration of the support surface. This decoupling can be achieved by reducing the contact surface between the incubator and the floor of the hood, but elastic layers can also be provided in contact with the support surface to improve insulation.

The main body is made of a material that has optimal acoustic performance, especially in the audible spectrum, although other frequency ranges may be advantageous, i.e., a sound absorption coefficient between 0.5 - 0.99.

The material must be biocompatible to ensure that sterile conditions are maintained at all times, even with accidental contact. This means that the material must have a low release of volatile organic compounds and must be antifungal.

Figure 1: Perspective view of the vibroacoustic control device.

The support means are integrated with the main body and allow the device to be vibroacoustically decoupled from the incubator structure.

The environmental regulation means consist of perforations or through holes arranged in the base and in the access means (they could also be in the side walls) that promote thermodynamic equilibrium and gas exchange between the device and the incubator.

The thickness of the walls can vary between 0.5 – 20 cm, so that the greater the thickness of the main body, the greater the absorption coefficient and the lower the biological stress inside.

The main body can adopt any geometric configuration that can rest stably on the interior surface of the equipment.

Access means can have an area ranging from 5% to 100% of the base surface. They can be single-piece or multi-piece, allowing access to different parts of the container. They can be partially (hinged) or completely (removable) independent of the main body, and can be closed using tongue and groove, adhesive, interlocking, screws, nuts, welding, slots, tabs, Velcro, clips, or other types of fasteners.

The surface area of the support media in contact with the incubator can range from 1% to 100% of the device footprint (the smaller this surface area, the lower the vibration transmission between the device and the incubator structure, and therefore, the lower the mechanical stress on the biological sample).

The perforations cover between 1% and 40% of the surface area of the base and access means and can take on various configurations in terms of number, location, and shape. These perforations can be distributed across any surface of the device, and their shape can adopt any known geometry. The ratio of the perforations to the total surface area of the device determines the total absorption area, influencing the mechanical stress on the biological sample. Ideally, the perforations are labyrinthine, with curves and/or breaks to limit sound entry.

The main body, the means of access, the means of support and the side walls may be independent elements and assembled by tongue and groove, adhesive, with nails, screws, nuts, welding, slots, tabs, Velcro, clips or other type of fastening, or they may be manufactured in an indivisible piece.

The device may also incorporate an active control system using electroacoustic transducers to selectively attenuate a specific band of the spectrum within the device, with the band being able to be selected by configuring or adjusting the transducers.

The biocompatible vibroacoustic monitoring device allows biological samples to be stored on plates or in appropriate containers, isolated from noise and vibrations, for the study of cellular dynamics.

ADVANTAGES OF TECHNOLOGY

The main advantages of this innovative device are listed below:

1) Mechanical stress is reduced at the cellular level by attenuating airborne and impact noise on the culture plate.

2) Vibration transmissions are reduced by decoupling the culture plate from the incubator structure.

3) Homogeneity in environmental conditions is improved by reducing fluctuations and vibroacoustic variations in the cellular environment. Therefore, the results obtained are independent of the equipment used and its configuration, thereby reducing variability.

4) Reliability and reproducibility in cell dynamics experiments are increased by minimizing masking phenomena caused by ambient vibroacoustic energy.

5) Sensitivity is improved in cell and molecular dynamics assays by reducing the mechanical stress that background noise from the incubator exerts on the biological sample.

6) The available space is optimized by allowing stacking. This stacking of different devices, in turn, increases the equivalent sound absorption area and results in a greater reduction in overall cellular stress.

7) The acoustic energy incident on the culture plate inside the device is reduced, which decreases mechanical stress on the biological samples.

INNOVATIVE ASPECTS OF TECHNOLOGY

There is no device on the market that protects cell samples from the noise generated by incubators and other devices, leaving biological cultures exposed to their effects on cell dynamics.

The design of this innovative biocompatible device has been specifically conceived for optimal vibroacoustic control of incubators and other devices related to the processing and/or handling of biological samples, significantly increasing cell survival and proliferation.

The object of the present invention is to comfortably, quickly and safely reduce mechanical stress in biological samples , thus improving the reliability and reproducibility of cell dynamics assays.

This innovative biocompatible vibroacoustic monitoring device for reducing mechanical stress in biological samples is at a TRL = 4 (Technological Readiness Level) maturity stage. In fact, an experimental prototype on a laboratory scale has been successfully built. (see Image 1).

Image 1: Experimental prototype built at laboratory scale.

Various tests have been carried out to verify the effectiveness of the device object of the invention, and it has been possible to reduce the acoustic energy incident on the culture plate inside the device by 20 dB at 500 Hz, 31 dB at 1 KHz and 48 dB at 5 KHz for a standard airborne noise signal measurement.

On the other hand, in cell dynamics tests, significant differences were obtained for the same cell line and seeding/incubation conditions, with an average of 0.735±0.100 and 0.644±0.183 for a culture plate placed inside the device and on the incubator tray, respectively.

Cell proliferation experiments were also carried out on the 661W transgenic murine retinal cell line, and cell proliferation was assessed using the crystal violet assay. The study was conducted under two experimental conditions: (i) "control", where the biological samples were exposed to the noise generated by the electromechanical systems and actuators within the incubator; (ii) "box", where the biological samples were placed inside the device object of this invention. The absorbance at 620 nm was quantified, and the following results were obtained for "control" and "box", respectively: 0.571±0.174 and 0.690±0.153. The results obtained reveal a statistically significant increase in cell proliferation in the "box" condition compared to the "control".

The present invention falls within the biological sector, specifically in the field of cell culture and the manipulation and/or processing of cultures.

This technology can be applied in a variety of contexts, such as incubators, biological safety hoods (especially laminar flow hoods), or anywhere where the sample is in a noisy or vibrating environment.

This is a particularly interesting device for carrying out studies in experimental biology and neuroscience.

They are looking for companies interested in acquiring this technology for commercial exploitation. through:

• Patent license agreements.

• Agreements on technology and knowledge transfer.

• Development of new applications.

Company profile sought:

• Manufacturers of insulating materials.

• Incubator manufacturers.

• Manufacturers of equipment for the processing and/or handling of biological samples.

The present invention is protected by patent application:

• Patent title: “Sample incubation or processing procedure, biocompatible vibroacoustic control device and use.”

• Application number: P202430552.

• Application date: July 2, 2024.

Pollution and Environmental Impact

Pharmacology, Cosmetics and Ophthalmology

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959