Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

EXCLUSIVE LICENSED

EXCLUSIVE LICENSED

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Waste, Pyrolysis and Combustion Group from the University of Alicante has developed a process for the possible elimination of printed ink from plastic films used in flexible packaging. Using this process, we can obtain an ink-free plastic film which can be easily reconverted to plastic pellets. At present there are no industrial methods for eliminating printed ink from these waste materials, and they can only be recycled with a very meagre increase in value. The process developed is completely novel and respects the environment, because it doesn’t use any kind of organic solvent. The most important advantages of ink elimination are, firstly, the increase in value of the treated plastic, even equalling the quality of new pellets, and secondly the sale price of recycled plastic compared with new plastic.

The technology has been tested successfully in different printing materials, such as polythene, polypropylene, polyester and polyamide. The process is viable for both solvent and water based inks. We are looking for recycling companies that may be interested in applying this process for treating and improving printed plastic.

The printing of flexible packaging consists of applying a liquid ink to a plastic film. After drying, the printed film is ready to be used as packaging for various products. Some of the most common plastics used are PE, PP, and PET.

During the printing of flexible packaging it is normal to adjust the parameters of the printing machine, as well as the different colours used, to achieve a print of the required quality.

The plastic film moves through the printer at high speeds, so large amounts of plastic of inferior quality is also produced. Most of the waste is generated in this part of the process, incurring losses of between 5 and 10% of the total production.

At present, this kind of material is recycled without eliminating the ink. A coloured film of low quality and value is obtained, which is normally used in basic applications such as rubbish bags. What is more, existing industrial processes offer no global solution to the problem of removing ink from printed film. Given the increase in price of raw materials it is becoming urgent to find a way of effectively recycling plastic waste and reducing production costs.

The process developed by the Waste, Pyrolysis and Combustion Group offers a global solution for this problem by removing the ink from the plastic film using different physical and chemical treatments. We obtain a pure, high-quality ink-free product, for recycling in a wide variety of applications.

The process proposed by the research group consists of various steps. First, the material is prepared. Then it is milled to the correct size for cleaning. Next, the ink is removed in cleaning tanks. The milled material is transferred to the tank, where water and cleaning agents are added.

During the process the ink is extracted continuously by a current of water that contains the cleaning solution and the ink. From this point onwards, different parallel steps are followed: the film is washed and dried while the cleaning solution and the pigment are recovered.

In the fourth step, the milled and treated film is soaked in a washing tank to completely remove the final remains of the ink and cleaning solution. Then the ink and the cleaning solution are separated in two flows.

The latter can be reused in the process and the former can be treated for the recovery of pigment. In the sixth stage the pigment is recovered by heating the ink. Finally, the film is dried after the washing phase to obtain a high quality plastic that can be reused as a raw material.

One of the main advantages of the process is that it produces both pigment and reusable plastic economically, increasing their final value, and waste is reduced to a minimum.

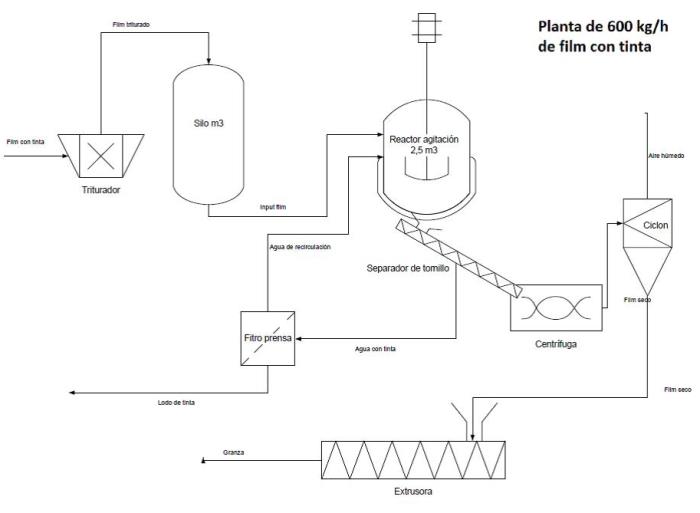

Figure 1: Diagram of a possible processing plant for 600 kg/h

The process doesn’t use organic solvents to remove the ink, so it is completely innovative and ecological.

Two products are obtained from the printed film: pigments, which can be reused after treatment, and recycled film, in the form of pellets, that can also be reused, because it has much higher quality than coloured film. The cleaning solution can also be reused, making it an attractive option both economically and ecologically.

The process can be applied to both printed products sold to an end user or waste from the printing process, so the film can take the form of reels of various widths and sizes, or irregular pieces.

The process has been tested successfully in a pilot plant on several plastic films (Polythene, Polypropylene, Polyester, and Polyamide). It has also been tested on both water and solvent based inks.

• At present printed film is only recycled for low quality applications, because the ink is not removed.

• The process obtains an ink-free plastic film which can easily be transformed into a new raw material for processing.

• The industrial process is economically viable because the value of the recovered material is increased.

• The process also recovers pigments that can be reused, so the waste generated is a minimum.

• The process for the removal of the ink is completely innovative and ecological, because it doesn’t use organic solvents.

• The technology has been successfully tested on different plastics, such as Polythene, Polypropylene, Polyester and Polyamide. It is viable for both water and solvent based inks.

• The plastic recycling industry

• The printing industry

• The packaging industry

We are looking for the following collaboration options:

• A license agreement for the implementation of the technology.• An R+D collaboration to complete the development of the technology or apply it to other sectors.

The Waste, Pyrolysis and Combustion Research Group is part of the Engineering Institute of Chemical Processes of the University of Alicante. This group includes teachers and researchers with more than 25 years of experience in the field of treatment and analysis of every kind of waste. The members of the group have published more than 100 articles in international scientific magazines and have presented more than 100 themes in national and international congresses. They have participated in more than 30 public projects and a similar number of private ones. The group therefore has a wide experience of the design, preparation and optimization of chemical processes, from laboratory to pilot plant scale.

Their main lines of research are the following:

Several members of the group are founders of the spin-off company Olax22 S.L. a technical company of the University of Alicante.

Engineering, Robotics and Automation

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959