Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Researchers of the University of Alicante have developed a new method to assess the durability of reinforced concrete. The parameter used is the diffusion coefficient of chloride ions, which is related to the transport speed of chloride ions through the concrete, and therefore the time it takes triggered embedded steel corrosion. This test requires saturated samples of concrete.

University researchers have developed a method to perform this test in a non-saturated medium, using conductive gels as chloride reservoirs.

The main advantage of this technology is the elimination of the liquid environments for testing, thus eliminating the medium saturation restriction. This allows determining the diffusion coefficient in partial water saturation states of the concrete.

One of the required parameters to calculate the estimated service life of the concrete, in relation to steel corrosion, is the chloride diffusion coefficient. There are several methods to determine this parameter, but have two major drawbacks: first pure diffusion assays require considerable time to execute and, on the other hand, shall be done in full saturated medium.

To accelerate this tests an electrical current can be applied to force penetration of ions into concrete. However it has been found an alternative to the saturated environment requirement.

Researchers of the Civil Engineering Department at the University of Alicante have developed a new method to overcome the restrictions of these techniques in terms of the requirements for concrete moisture.

The proposed method provides the use of two conductive gels in each side of the concrete specimen.

The first conductive gel is a gel consisting of a matrix with Cl- ions (NaCl for example) and a binder compound. This gel is in contact with one face of the concrete test specimen, and is connected through an electrode to the negative pole of a power source.

The second conductive gel is a gel similar to the above mentioned and with the same ionic conductivity, but formed by a free Cl- matrix ions (NaNO3 for example). This gel is placed on the opposite side of the specimen and is connected through a second electrode to the positive pole of the power source.

By connecting the power source, anions contained in the gel NaCl are forced to pass through the concrete being tested, obtaining an appropriate chloride profile to set the migration coefficient of concrete.

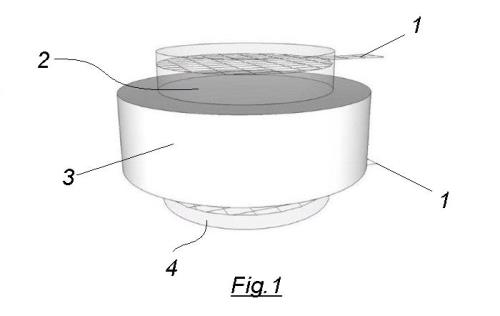

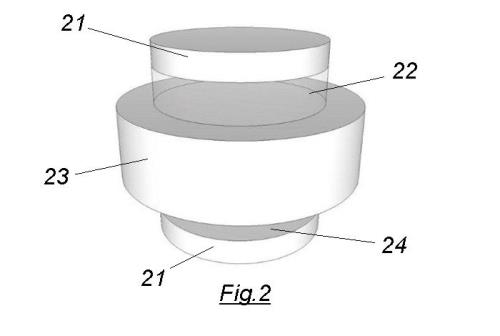

Two configurations of this technology can be seen in the pictures. The difference is that in Figure 1 the electrodes are metal mesh embedded in the conductive gel and in Figure 2 the electrodes are disks in contact with the gel.

1. Mesh electrode embedded in the conductive gel

2. Conductive gel with NaCl matrix

3. Concrete test specimen

4. Conductive gel with NaNO3 matrix

21. Disc-shaped electrodes in contact with the conductive gel

22. Conductive gel with NaCl matrix

23. Concrete test specimen

24. Conductive gel with NaNO3 matrix

KEY BENEFITS OF TECHNOLOGY

The main advantage of this technology is that it avoids the concrete saturation requirement for the concrete durability tests. Technology also provides other advantages such as:

• Prevention of sealing problems deriving from the use of liquid solutions.

• This method can work in a less restrictive and closer to reality medium.

• Ensures a better definition on the advancing front edge, ensuring good measurement accuracy.

• The use of conductive gels is not a significant additional cost.

• One of the electrodes can be replaced by one of the steel bars embedded in the concrete for the implementation of the method in real structures or samples.

INNOVATIVE ASPECTS

The main system innovation is the use of ion conductive gels as reservoirs of chlorides in migration assays.

Until now the techniques had to start with the full saturation of the specimen and keeping it in contact with a chloride ions solution during diffusion or migration tests. This guaranteed the absence of other transport mechanisms (such as capillary absorption) and avoided surface moisture changes. This new method is simple to implement and allows the elimination of these requirements.

Another innovative feature is that the system allows greater measuring accuracy of the advancing chloride front, because this advance occurs more homogeneously than in conventional tests in contact with liquid solutions.

Today this technology has been tested through different experiments that have validated the effectiveness of this method and optimum formulations have been obtained for conductive gels. The method is available for implementation in real tests.

This technology is of interest to various companies in the building industry as concrete manufacturers, material testing laboratories, construction, architecture, etc.

We are looking for companies interested in acquiring the technology for exploitation.

It is possible to use different forms of technology transfer (licensing agreement of the patent, transfer of rights of use, manufacture or sale to other companies, etc.).

The technology is protected by patent application.

Patent in Spain:

• Application Number: 201200768

• Date of application: 26/07/2012.

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959