Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

There exist numerous catalysts for decomposing N2O. Unfortunately, most of them have been studied at laboratory scale employing a N2O stream diluted in an inert gas. Although, the most common situation is finding N2O with a mixture of gases (N2O, O2, NOx, H2O, etc) which inhibit importantly the catalyst, avoiding its implementation at industrial scale.

Nitrous oxide (N2O) is an environmentally harmful gaseous compound. N2O is a greenhouse gas with tremendous global warming potential. It also causes ozone depletion. N2O emissions mainly come from:

• Nitric and adipic acid manufacturing plants

• Biomass combustion

• Fossil fuels

• Agricultural soil management

• Exhaust gases from vehicles

N2O concentration in the atmosphere is increasing by an average of 0,2% per year. Accordingly, the development of adequate methods for their removal and/or their controlled emission have become global imperatives. The currently used methods consist of the decomposition of N2O to molecular oxygen (O2) and nitrogen (N2). The main drawback of this procedure is the high temperatures needed (more than 625ºC) so that a spontaneous decomposition takes place. However, a molecule could be decomposed at lower temperatures by using an appropriate catalyst.

This catalytic system is composed of:

a) An active phase: rhodium (Rh) supported on a cerium-other(s) metal(s) mixed oxide. The amount of Rh depends on the application of the catalytic system.

b) A physical support: inorganic materials such as pellets, silica or aluminium particles, cordierite honeycomb monoliths, etc.

The procedure for the preparation of this novel catalytic system comprises the following phases:

1) The selected support is impregnated with a solution containing a cerium and other(s) metallic(s) salts.

2) Drying.

3) Calcination.

4) The mixed oxide previously supported is then impregnated with an aqueous solution of a Rh salt.

5) Drying.

6) Calcination.

It is worth mentioning that the reduction of the noble metal is not necessary when preparing this catalytic system.

The main advantages of this technology are:

• New, active, effective and stable catalytic system in real operating conditions at industrial scale.

• Their activity remained constant over time irrespective of the working conditions employed.

• Apart from the catalytic activity, other physical-chemical properties (crystalline structure of the mixed oxide, catalyst surface area, Rh particles size and Rh oxidation state) also kept nearly constant after more than 40 non-consecutive hours of catalytic assays in real operating conditions in a nitric acid manufacturing plant.

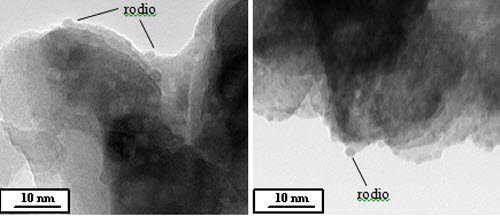

Images taken using transmission electron microscopy. Left: Fresh catalyst; Right: Catalyst used during 40 non-consecutive hours in a N2O decomposition assay in a nitric acid manufacturing plant. As it can be observed, the rhodium particles size (approximately 1-2 nm) is not modified during the assay.

The main innovative aspect of this invention in comparison with the commonly used for these purposes is its ability for working at oxidant atmosphere in presence of inhibiting gases (such us O2, NOx y H2O) at 300ºC or higher temperatures.

This invention refers to a novel, effective, active and stable catalytic system able to remove N2O by direct decomposition to O2 and N2 in complex waste gases such us:

• Chemicals manufacturing plants (Nitric acid, adipic acid, caprolactam, acrylonitrile, glyoxal, etc.).

• Processes in which nitric acid or ammonia are used as oxidant agent.

• Combustion processes of fossil fuels (carbon, biomass, wastes, etc).

• Vehicles emissions (petrol engines, diesel engines, etc.)

• Others.

These kinds of effluents are characterized by containing a low N2O concentration (between 500-500 mg/L) at temperatures less than 525ºC and in the presence of inhibiting gases (O2, NOx, H2O…).

This technology is protected by patent:

• Application number: P200901897.

• Application date: 23/09/2009.

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959