Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Carbon Materials and Environment research group in University of Alicante has developed a mixed oxide based catalyst for the effective elimination of chlorinated volatile organic compounds (specially 1,2-dichloroethane) in gaseous streams at low temperatures (250-500ºC).

This is a low cost, active and stable catalyst which is insignificantly deactivated in the presence of chlorine. The catalyst is totally developed at laboratory scale and protected by patent. The researchers are looking for industries licensing this technology.

Over the past few years, the environmental legislation has become stricter with the permitted limits of atmospheric emissions, particularly with the emission of volatile organic compounds (VOCs) because of their damaging effects for both environment and human health. Although there exists a wide variety of VOCs (depending on their chemical structure, emission sources, etc.), the 1,2-dichloroethane (DCE, C2H4Cl2) is the most stable, hazardous and frequently used VOC in the industry (e.g., in the production of polyvinyl chloride (PVC)).

Nowadays, the catalytic oxidation is the most currently employed method to remove VOCs due to its availability for breaking them down at low temperatures. Also, the formation of secondary pollutants (nitrogen oxides) is strongly reduced. Catalytic oxidation processes require heating up large gas flows and putting them in touch with a solid catalyst. To this end, two types of catalysts are employed:

• Catalysts containing noble metals as active phase: They show high oxidation efficiency, although their cost is also considerable. In addition, they gradually lose their activity in presence of chlorine in the reaction medium.

• Catalysts containing transition metals: They are cheaper, more stable and lasting than the former ones. However, their activity is lower.

Many of the catalysts devoted to the combustion of VOCs are deactivated when used to remove chlorinated VOCs because of poisoning from chlorine. Then, they stop working properly in a very short time. For that reason, a catalyst which allows the destruction of chlorinated VOCs without suffering a rapid deactivation (in time and use) is needed. Accordingly, a new catalyst for activating the combustion of chlorinated VOCs has been synthetized by a Spanish research group. Its general formula is the following:

Obviously, both chlorination reaction on the catalyst and their stability depend on the mixed oxide composition. These kinds of catalysts are prepared by dissolving the appropriate precursors in aqueous solution and precipitating/co-precipitating the adequate hydroxides. Subsequently, the obtained solution is filtered, dried and finally calcined.

This novel cerium–praseodymium mixed oxide based catalyst allows to efficiently manage the emissions of chlorinated VOCs, specially of DCE, due to its large proportion in gaseous streams of chemical plants, its high stability and toxicity.

The major advantages of this catalytic system relative to others commercially available in the market are:

• High efficiency.

• High stability and durability.

• Low production cost.

• Low amounts of catalyst are required for working properly.

• Secondary pollutants (nitrogen oxides) are not generated.

• Gaseous streams at low working temperatures (250-500ºC) can be treated.

INNOVATION ASPECTS

The main innovative aspect of the new Ce-Pr mixed oxides catalysts is their suitability for an efficient combustion of chlorinated VOCs (especially 1,2-dichloroethane).

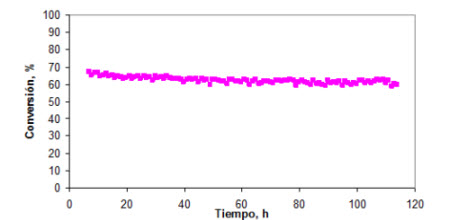

These novel catalytic systems are able to actively operate in gaseous streams at temperatures between 250-500ºC for a long time without undergoing deactivated significantly.

This stable catalytic system for the effective combustion of chlorinated VOCs has an important application in the emission control in the following industrial activities:

• PVC production.

• Cleaning of textile products.

• Cleaning of metallic pieces.

• Dispersion of plastics and elastomers.

• Paintings.

• Enamel and varnishes.

• Waste gases from chemical plants.

• Solvent evaporation.

• Water and soil decontamination.

This technology is protected by patent:

• Application number: P201130641.

• Application date: 20/04/2011.

Pollution and Environmental Impact

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959