Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group "Atomic-mass spectroscopy and analytical chemistry under extreme conditions" of the University of Alicante has developed a new pneumatic multicapillary nebulizer that it allows the simultaneous nebulization of two or more liquids -miscible or immiscible between them- through different independent liquid input capillaries, and provided with a single exit orifice for the aerosol generated. The device offers the possibility of simplifying the analysis process and reducing the consumption of resources (i.e., time, sample and reagents). In addition, a high mixing efficiency is achieved, with stable emulsions and excellent aerosol characteristics. Moreover, it can be connected to any commercial spray chamber. A laboratory-constructed prototype is available for any demonstration. This device can be used as a sample preparation and liquid sample introduction system in spectrometric techniques within the field of chemical analysis. The research group is looking for companies interested in transferring this technology for commercial exploitation.

Currently, three different multiple nebulizer-based system types are known:

1) Systems that incorporate several spray chambers, each one being equipped with a conventional nebulizer. These systems are complex to handle and a low mixing efficiency is achieved.

2) Systems that incorporate several conventional nebulizers in a modified spray chamber. These systems are easier to handle in comparison with the preceding ones. However, the mixing efficiency critically depends on the nebulizer position in the spray chamber.

3) Systems that incorporate one nebulizer with several aerosol outlet orifices and several independent liquid input capillaries (multinebulizers). In these systems, the greater proximity between the aerosol outlet orifices could increase the mixing efficiency.

In order to overcome the limitations described above, a novel multicapillary pneumatic nebulizer has been developed which allows the simultaneous nebulization of different liquids, miscible or immiscible between them, by means of several independent liquid input capillaries with a single aerosol outlet orifice.

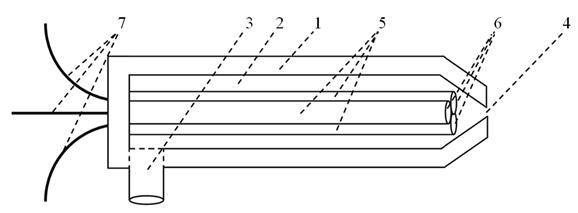

As shown in Figure 1, the nebulizer outer body (1) comprises a pressure chamber (2) for the flow of a nebulizing gas and an inlet tube (3) of said gas and an outlet orifice (4) thereof, open to the outside. Within the pressure chamber a plurality of liquid input capillaries (5) is housed, said capillaries preferably arranged in parallel, whose outputs (6) are commonly positioned in the area of the aerosol outlet orifice and whose inputs are connected to liquid feeding tubes (7), so that each liquid input capillary is connected to a separate liquid feeding tube. Liquid flows to be nebulized are aspirated or pumped through the various feeding tubes and through the liquid input capillaries of the nebulizer, located within the pressure chamber. At the exit of the liquid input capillaries, the liquid flows interact with the gas flow at high or low speed, and at high or low pressure in the pressure chamber; liquid and gas flows mix together, forming the aerosol which is pushed towards the outlet orifice of nebulizer expelling the nebulized product to the outside.

Figure 1. The multicapillary nebulizer comprises: (1) nebulizer outer body; (2) pressure chamber; (3) gas inlet; (4) output orifice of the aerosol; (5) liquid input capillaries (sample, calibration standards, reagents, solvents, etc.); (6) exit orifices of the liquid input capillaries; (7) liquid feeding tubes.

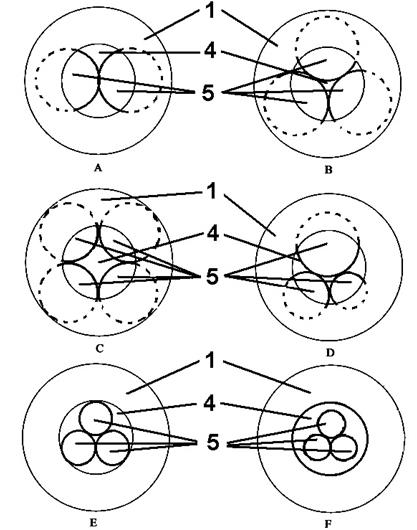

The developed device can adopt several embodiments, providing a high versatility to adapt to different applications. For example, Figure 2 shows several embodiments, without limiting them, using different quantities and geometries of the liquid input capillaries.

Figure 2. Some of the possible embodiments of the multicapillary nebulizer (front view) showing a different quantity (2, 3 or 4) and/or a different geometry (symmetry and diameter) of the liquid input capillaries and their location and dimension relative to the exit orifice of the aerosol, wherein: (1) nebulizer outer body (4) exit orifice of the aerosol and (5) liquid input capillaries.

MAIN ADVANTAGES OF THE TECHNOLOGY

This multicapillary nebulizer has the following advantages over current multiple nebulizer devices of the state of the art:

• A high mixing efficiency between different nebulized liquids in the aerosol droplets is achieved because the mixing takes place under turbulent conditions of high pressure and speed.

• Even if liquids are not miscible, the device obtains stable emulsions during the time in which the droplet is transported to the plasma.

• It can work either in a conventional way (by nebulizing a single liquid: sample or calibration standard), or by combining the sample preparation and sample introduction by simultaneous nebulization of different liquids.

• The work performed manually is reduced and simplified.

• Uncertainty is reduced and accidental errors in the analysis process are eliminated.

• Significant time saving.

• The amount of samples and reagents are reduced.

• Some processes are intensified due to the high pressure and speed of liquid flows in the mixing zone.

• The nebulizing gas flow is not divided between different exit orifices, so the working conditions are equal to the optimum working conditions of the spectrometer. In this way, the quantity of liquid input capillaries can be adjusted to the specific application of the nebulizer.

• It can be constructed using adequate dimensions to allow the connection to any commercial spray chamber (for all manufacturers and models of spectrometers based on plasma).

• Depending on the geometry of the exit orifice of the aerosol, an aerosol with excellent characteristics can be achieved over a wide range of liquid flow leading to different nebulization mechanisms.

INNOVATIVE ASPECTS

This multicapillary nebulizer allows simultaneous mixing and nebulization of two or more liquids, miscible or not.

This device differs from other conventional nebulizers or multiple nebulizers, by the large number of independent liquid input capillaries with a single exit orifice of the aerosol.

Experiments and tests have been performed to confirm its reliability, reproducibility, robustness and that it is easy to handle.

Figure 3. Photograph of the laboratory-constructed prototype

The present invention falls within the field of liquid nebulization technologies. Specifically, this device allows mixing and nebulizing two or more liquids, which makes it particularly suitable for sample preparation and liquid sample introduction in spectrometric techniques in the field of chemical analysis.

The multicapillary nebulizer can be used for the following:

• Sample dilution (allowing the automatization of the dilution process).

• Internal standard calibration (allowing interference corrections).

• Standard addition calibration (allowing the automatization and simplification of the process).

• Isotopic dilution analysis.

• Derivatization and chemical vapour generation of analytes (allowing chemical reactions to take place in aerosol phase between the analytes of the sample and calibration standards, and one or more reagents).

• Organic sample analysis (allowing the organic sample analysis in the plasma by emulsifying with aqueous solutions. A high mixing efficiency is achieved and the formation of carbon deposits on the exit orifice of the injector tube is removed).

• Liquid-liquid extraction (reducing the experimental time, analyte losses and sample contamination. In addition, large sample amounts, expensive organic reagents and/or toxic ones are not required).

• Discrete samples/standards introduction (directly introducing the analyte in a discrete way in aerosol phase into the spray chamber, removing diffusion problems).

• Medical and Health related:

o Diagnostic: Forensic science.

o Therapeutic: Drug delivery and other equipment.

o Clinical medicine:

- Pulmonary medicine.

- Ophthalmology, ear, nose and throat diseases.

• Other electronics related: analytical and scientific instrumentation (other analytical and scientific instrumentation).

Companies interested in acquiring this invention for commercial exploitation by:

• Patent license agreement.

• Searching for financial support in order to develop new applications, adapt to specific requirements of the company, etc.

• Technology and knowledge transfer agreements.

• Preparing technical reports and providing scientific advice to companies.

• Providing specific training adapted to company requirements.

• Services of standardization, calibration, development of national and international technical standards, etc.

• Providing technical support in those techniques that require highly skilled researchers or sophisticated instruments that are not available to the company.

• Personal exchange for a defined period of time (for learning a technique, etc.).

• Equipment rental to customers who wish to carry out their own tests (at the Department of Analytical Chemistry or Technical Services Research (SSTTI) of the University of Alicante).

The present invention is protected by patent rights:

• Title: “Nebulizador multiconducto, uso de dicho nebulizador y método para la nebulización de dos o más líquidos”.

• Application number: P201431797

• Application date: 4th December 2014

• Professional, scientific and technical activities: scientific research and development (research and experimental development on natural sciences and engineering).

• Education: higher education.

Pollution and Environmental Impact

Medicine and Health

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959