Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Researchers from the University of Alicante have developed an innovative sample holder designed for use with scanning tunneling microscopes (STM). Thanks to a rail system, the sample holder allows for a quick sample exchange without the need to disassemble the equipment or recalibrate its critical components. Additionally, it enables seamless switching between different techniques.

Its versatile design accommodates various sample sizes and types, including electrochemical samples, ensuring mechanical stability and atomic precision. Furthermore, this sample holder allows for scanning a larger surface area.

This technology is ideal for laboratories that frequently use this type of microscope.

A scanning tunneling microscope (STM) provides high-resolution images of surfaces at the atomic level and enables the study of the electronic properties of materials.

Operating an STM microscope is highly complex due to the need to completely disassemble the equipment and remove multiple components to change samples. Once the new sample is inserted, all components must be reassembled and recalibrated. This process can lead to errors that affect the quality of the obtained images.

As a result, sample replacement is a time-consuming and labor-intensive process that requires skilled technicians to handle all these tasks, as errors can damage the sample or lead to incorrect system calibration.

Traditional STM microscopes lack versatility, as they are not designed for continuous sample swapping. Changing a sample involves tedious and inefficient disassembly.

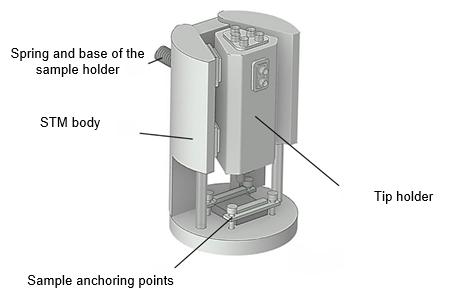

Fig 1. PAM-type STM Scanning Tunneling Microscope sample holder from a front and rear perspective

The sample holder developed by researchers optimizes sample handling in scanning tunneling microscopes (STM) through an innovative rail system that allows for quick sample insertion and removal without disassembling the equipment or recalibrating displaced components. This design reduces operational time and complexity while ensuring high mechanical and electrical stability for high-quality imaging with atomic resolution.

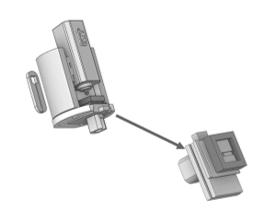

The invention replaces the STM microscope’s sample stage with a system consisting of a base that is directly fixed to the microscope body and a rail mechanism that enables the sliding of the removable stage for quick insertion and removal. This stage includes several elements to hold and secure the sample. As a result, samples can be replaced without dismantling the STM microscope or modifying the spring configuration.

The sample holder is made of PLA, a 3D-printable material with high mechanical stability, very low cost, biodegradability, and a plant-based origin. However, other materials can also be used.

The invention has proven effective under various conditions, including ambient and low-temperature environments, and is compatible with metallic and electrochemically prepared samples. Its design eliminates vibrations and facilitates the analysis of larger surfaces through a rotation system, ensuring reproducible, reliable results with atomic precision.

Fig 2. Proposed sample holder

MAIN ADVANTAGES OF THE TECHNOLOGY

The key advantages of this technology include:

• Fast Sample Exchange: The rail system enables sample insertion and removal in seconds, significantly reducing the time required for sample changes.

• Ease of Use: Simplifies sample handling and assembly, eliminating the need for disassembly and reassembly of the microscope, and removing the requirement for specialized technicians to recalibrate the system afterward.

• Preservation of Microscope Calibration: The design maintains the system’s spring position, eliminating the need for recalibration after each sample change.

• High Image Resolution: The system enables atomic-resolution imaging, as samples remain clean and free from electronic or mechanical interference.

• Vibration Reduction: The device’s design, particularly the pressing frame and rails, minimizes vibrations, improving image quality.

• Mechanical and Electrical Stability: The system allows for high-resolution imaging of metallic surfaces and electrochemically prepared samples, even in ambient conditions.

• Larger Surface Scanning: The manual rotation option expands the system’s capabilities, allowing for the scanning of larger sample areas.

In summary, this technology optimizes performance, reduces operational complexity, and enhances the user experience in scanning tunneling microscopy.

INNOVATIVE ASPECTS

The most notable innovation of this technology is the ability to insert and remove the sample holder in seconds, thanks to the rail system, eliminating the need to disassemble the microscope or manipulate critical components.

The proposed design enables easy handling and maintains the microscope’s calibration between samples. This ensures stability, high image resolution, and minimal vibrations.

Overall, the usability and functionality of scanning tunneling microscopes (STM) are improved, making the technology more accessible, versatile, and efficient.

The research team has explored various designs and conducted multiple experimental tests. The current configuration has been optimized for maximum precision.

A laboratory-scale prototype made of PLA has been developed, and laboratory tests have been conducted to verify its functionality and effectiveness. The system is ready for industrial scaling and subsequent market introduction.

This technology is designed to optimize the use of scanning tunneling microscopes (STM), making it valuable for companies and research centers that utilize these analytical techniques.

It is particularly relevant for companies manufacturing STM microscopes or their components.

Companies interested in acquiring this technology for commercial exploitation are sought through:

• Knowledge licensing agreements.

• R+D (technical cooperation) project agreement for developing projects related to this technology.

This technology is protected by a patent application.

• Patent Title: “Portamuestras de microscopio de efecto túnel”

• Application Number: P202430886

• Application Date: 30/10/2024

Medicine and Health

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959