Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Engineering Design and Technological Development (DIDET in Spanish) group from the ArtefactosLAB laboratory of the University of Alicante has developed a soprano recorder designed so that children with motor disabilities in any of their upper limbs can learn to play it with only one hand.

The aim is the inclusion of these groups as part of society and the improvement of their autonomy, self-esteem and quality of life.

The group is looking for companies or institutions interested in continuing to develop the device or in the design and manufacture of new ones.

Currently, there are several adapted soprano recorders, but they are designed with a very generic approach and aimed more at the professional than the school environment. These recorders are made of high-quality materials such as wood and metal, using industrial or artisanal manufacturing processes, so their cost is high, in addition, these models are quite heavy and comprise small metal keys, with a cylindrical and flat shape, which makes them difficult to use.

On the other hand, 3D printing or additive manufacturing has become a productive alternative to traditional industry, a technique usually used in engineering for the generation of prototypes but which has now been introduced in many sectors for short series due to the low cost of the materials and equipment required, its great flexibility and capacity for customisation. The use of other manufacturing processes would increase costs (due to the low number of manufacturing units required), making it unfeasible to manufacture any object or device.

For people with functional diversity, additive manufacturing is a great advance as it offers viable products at a productive level, accessible to many of those who need them and personalised for each user.

Until now, children with motor functional diversity have found themselves in a situation of exclusion in music classes in schools. Either because they are obliged to change instruments because they cannot play with both hands, or because they are assigned tasks other than those of the subject, such as painting or reading, while the rest learn to play the flute. This prevents them from continuing with the same practice as the rest of the class, which slows down their pace of learning.

For all of the above reasons, it is necessary to design a soprano recorder that is easy and inexpensive to manufacture.

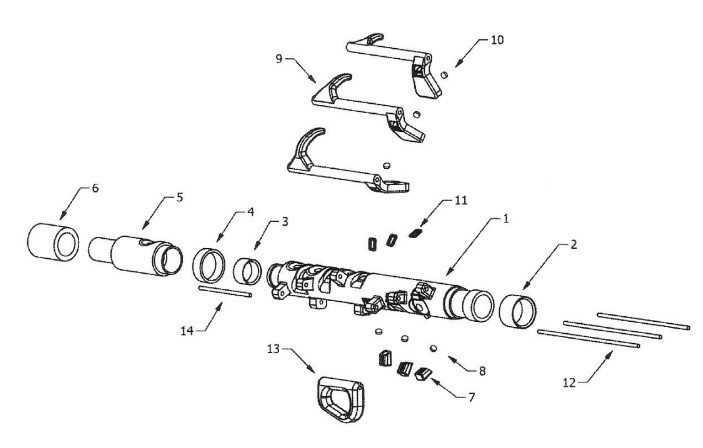

The present invention consists mainly of (see Figure 1):

• Flute base.

• Key mechanism.

• Thumb grip ring

• Flute foot

Figure 1: Perspective view of the adapted body of the flute showing the different parts that make up the design. Base (1), adjustable strap (2 and 3), trim (4), foot (5), anti-slip protector (6), magnet covers (7), magnets (8 and 10), keys (9), rubbers (11), metal rod (12 and 14) and grip ring (13).

On the base of the recorder is mounted the key mechanism, the thumb grip ring and the foot of the recorder, all of which allow the recorder to be used with one hand independently and without the need for any other support.

A conventional soprano recorder mouthpiece (commercially available, not included in the design) is inserted at the upper end. Both the upper and lower ends are cylindrical in shape and are surrounded by an adjustable element to prevent air loss during use. In the central area, there are three holes at the front for closing and opening directly with the fingers, and three more at the back for closing and opening by means of the keys.

The key mechanism, on the other hand, consists of different parts. The set of three keys, together with the three upper holes in the base of the flute, allow the creation of three musical notes (B, A and G), the rods serve as the axis of articulation, the shoes allow the closing of the holes, the rubber bands keep the keys in closed position while offering a smoother and more controlled movement of the key during the keystroke, the magnets are the attraction elements to increase the pressure on the keys and ensure that the holes are closed, and finally, the sleeves house the magnets that are attached to the body and allow to dampen the metallic click that the magnets generate when they are joined together, favouring the optimum sound quality of the instrument.

The sleeves, like the base, are made of rigid resin, while the pads are made of Evatex foam, the rubbers of natural rubber, the magnets of Neodymium metal and the sticks of stainless steel.

The grip ring is mounted on the base of the flute by means of a rod, allowing the user to hold the flute with just the thumb, leaving the other four fingers free to create the musical notes.

The foot of the flute, which contains the last hole (corresponding to the note C), is mounted on the base of the flute at the end of the instrument's main tube and includes, at one end, a trim and, at the other end, a non-slip protector to prevent breakage due to impacts or falls and to improve the grip when the instrument is placed on surfaces.

MAIN ADVANTAGES OF THE TECHNOLOGY

This soprano recorder has a number of outstanding advantages:

• Adapted for playing using only the five fingers of one hand (left or right-handed), four fingers for opening and closing the holes and the other finger for holding the recorder.

• Smooth but resilient finish.

• Dimensionally stable, strong, durable parts with good precision and durability.

• Quick and easy access to spare parts.

• Easy to learn and use thanks to its lightness and ergonomics.

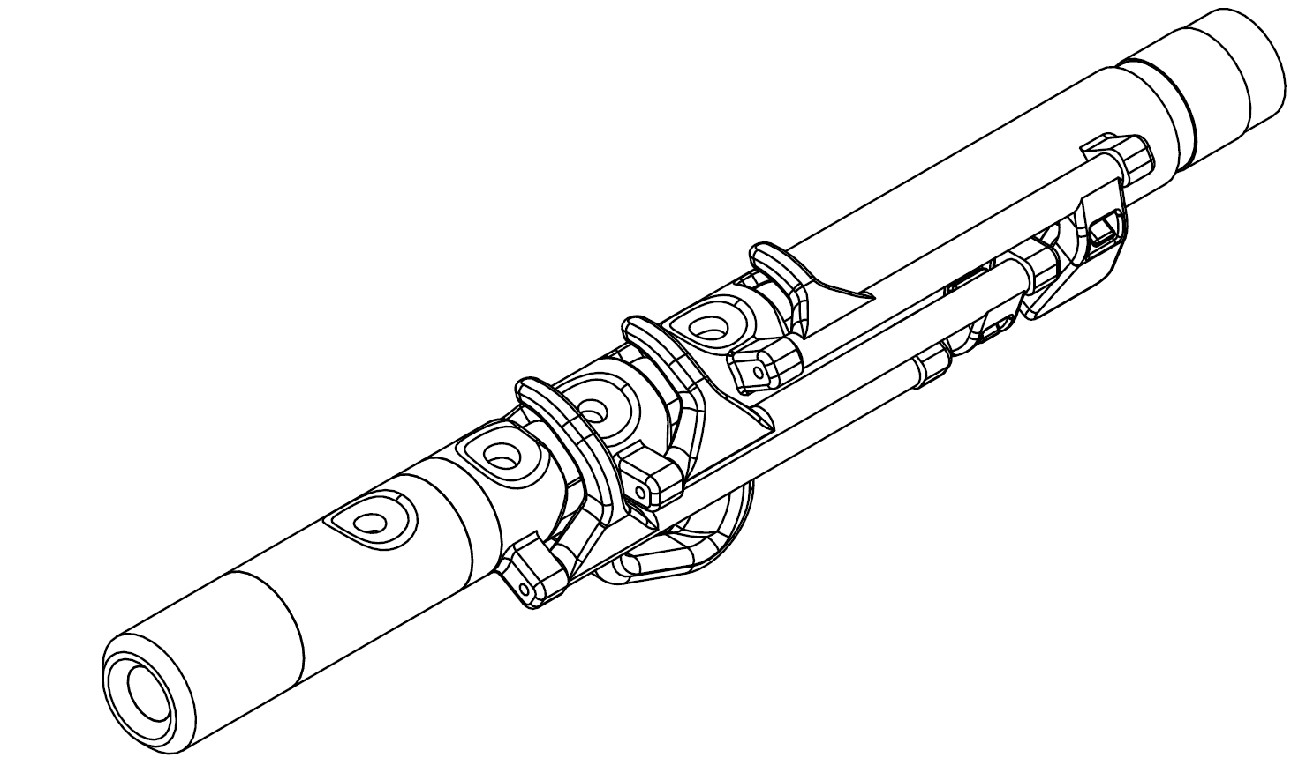

• Offers a compact finish and unique aesthetics to appeal to both boys and girls (see Figure 2).

Figure 2: Perspective view of the fully assembled flute.

• Improving the autonomy and therefore the quality of life of school-age children.

INNOVATIVE ASPECTS

3D printing, together with the use of three-dimensional models, has become an alternative manufacturing process to the conventional one. Its application within assistive technologies opens up endless possibilities for improving the quality of life of people with functional diversity, mainly due to the following factors:

• Low cost of materials and equipment needed.

• Freedom of design that allows to approach to personal needs and to obtain totally personalised devices.

• Speed of manufacture.

• Manufacture anywhere in the world, giving the user or music education professional the possibility of self-manufacturing their own device, which also means savings in logistics and distribution.

The instrument obtained is the result of the participation of different people with functional diversity with whom the dimensions and performance of the flute have been tested and adjusted. In addition, different professionals linked to music teaching have also collaborated. Therefore, it is a device that perfectly fulfils the objectives sought and is already being used regularly even by people without any type of motor disability.

This invention is framed within assistive technologies. It is mainly focused on the first stage of school music education, although it could also be a support tool in other areas in which both the improvement of cognitive abilities and physical skills are worked on.

3D printing or additive manufacturing is a technique that can be applied to satisfy any need, in any field, that a person may have. It is especially useful for people with functional diversity with very personal problems in fields such as medicine, education, work or mobility.

From ArtefactosLAB, the DIDET group is looking for companies or institutions interested in supporting the development of the instrument or in the design and manufacture of other devices for people with functional diversity.

This technology is protected by a utility model application.

• Title of the utility model: "Flauta dulce soprano adaptada para tocar con una mano."

• Application number: U202131434

• Date of application: 08/07/2021

Engineering, Robotics and Automation

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959