Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Applied Electrochemistry and Electrocatalysis research group at the University of Alicante has developed a device for desalinating food products based on the electrodialysis technique.

The application of an electric field to the device containing the food product to be desalinated causes and allows the movement of the sodium (Na+) and chloride (Cl-) ions contained in the product, leaving the product desalinated, considerably shortening both desalination time and water consumption, compared to other more common methods.

The device, which is protected by a patent application, has been developed on a laboratory scale using salted cod as a food product. The research group is currently developing a prototype to be applied in the hotel and catering industry.

Companies interested in the commercial exploitation of the technology are being sought.

Currently, several methods are used in the food industry for the desalination of a salted food product. The most commonly used method is based on the immersion method, which can be either continuous or batch. However, this method does not allow precise control of the variables in the desalting process in order to considerably shorten desalting times and minimise water consumption.

The electrodialysis technique is an electrochemical separation process that moves the salt dissolved in water to another solution, using electrical energy in the form of direct current applied between two electrodes - one negative (cathode) and one positive (anode) - through selective ion exchange membranes. At the cathode, the reduction reaction of water to hydrogen mainly takes place, while at the anode, the oxidation process of water to oxygen mainly takes place. The selective ion exchange membranes allow the anions and cations present in the salt dissolved in the water (dilute compartment) to be transported to the concentrated compartment, leaving a desalinated solution.

The electrodialysis technique is currently applied in the food industry on liquids such as wines, to obtain a certain degree of demineralisation and to stabilize tartaric acid. There are also described applications of electrodialysis to reduce the acidity of tropical fruit juices, increasing their use as an ingredient in the manufacture of some products such as ice cream, drinks, jams, cakes and cocktails. It is also applied in the food industry to demineralise, deacidify and desalinate whey left over from cheese and butter production, obtaining proteins and by-products with high added value such as calcium, making them suitable for direct marketing or for making dairy beverages.

Therefore, there is a need to develop a desalination method applied to solid foods containing significant amounts of salt that can use smaller quantities of water and significantly reduce the times used in the immersion method.

The Applied Electrochemistry and Electrocatalysis research group of the University of Alicante has developed a device to desalinate a solid salted food product based on the application of the electrodialysis technique.

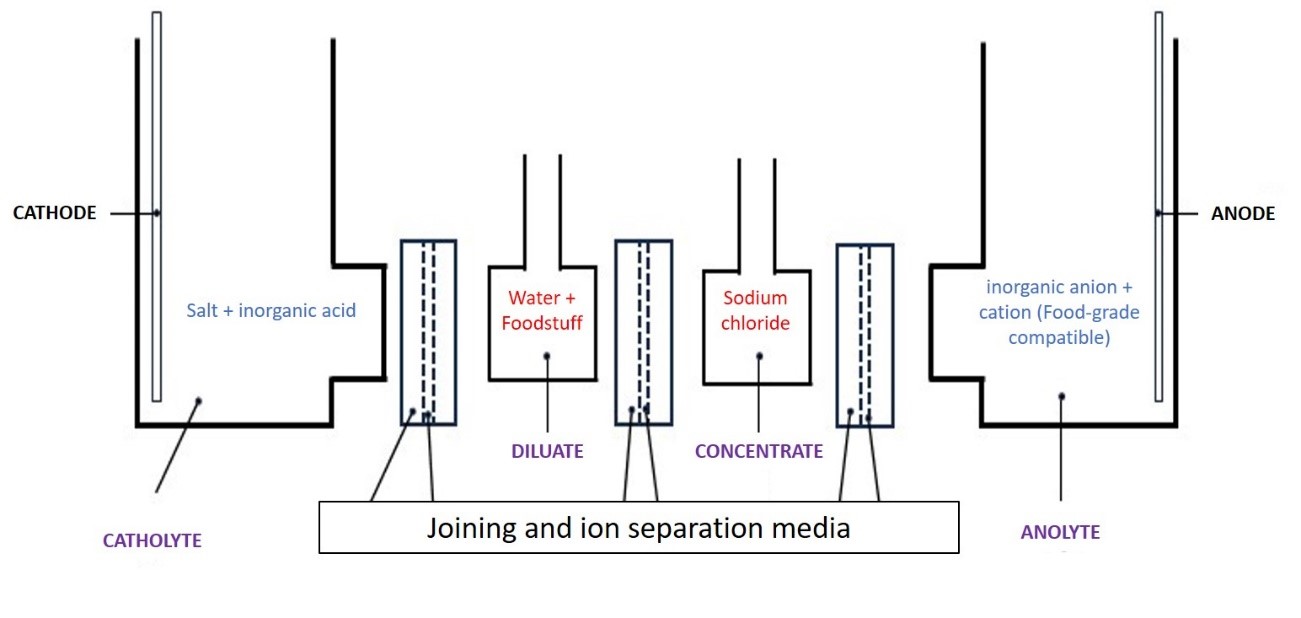

The device consists of four compartments linked in series between which are arranged ion exchange membranes (Figure 1):

1. CATHOLYTE: A compartment containing a solution of at least one salt and/or inorganic acid, compatible with food use. The first electrode, more specifically the cathode, is immersed in it;

2. DILUATE: A compartment containing one or more pieces of foodstuff salted in water;

3. CONCENTRATE: a compartment containing a sodium chloride solution;

4. ANOLYTE: A compartment containing a solution of an inorganic anion and an inorganic cation compatible with food use, with a second electrode immersed in this second solution, more specifically the anode.

Figure 1. Schematic of a front view of the device.

To carry out the desalination of the food product by electrodialysis, a piece of the food product is first introduced into the DILUATE. An electric field is then applied between the two electrodes of the device. This current flow between the electrodes triggers the following processes:

• oxidation of water to oxygen at the anode (2H2O ---> O2 + 4H+ + 4e-);

• hydrogen formation at the cathode (2H+ + 2e- ---> H2)

• migration of the ions presents in the different solutions : the anions and cations presents in the DILUATE compartment, which come from the salted food product, travel through the ion exchange membranes towards the CONCENTRATE compartment and the CATHOLYTE compartment, leaving a desalinated solution in the DILUATE compartment.

More specifically:

• the anions present in the DILUATE are transported to the anode;

• the cations present in the DILUATE are transported towards the cathode;

• the ion exchange membranes cause the ions (anions and cations) to migrate from the DILUATE causing the solution in the DILUATE to lose salinity and also desalting the food product by forcing the chloride (Cl-) and sodium (Na+) ions out of the food product into the solution

• Simultaneously, the CONCENTRATE gains salinity.

Given the low value of the current density that is circulated, the amount of gases generated is very low and there is no significant risk in the handling of the device.

By circulating a direct electric current, the time of process and the intensity of the current are related to the amount of salt that is removed from the food and therefore allow to choose the desired degree of desalination. The nature and low value of the electric current does not alter the quality of the desalinated product.

The desalination time is variable as it depends on several factors, such as: size of the food product, thickness of the food product, percentage or degree of desalination to be achieved for a culinary application.

TECHNOLOGY ADVANTAGES

The device developed by researchers at the University of Alicante to desalinate food products has the following advantages:

• It makes it possible to desalinate a salted food product, using a quantity of water that is normally less than that used in conventional processes and in a much shorter time.

• It avoids having to replace the water periodically or to be continuously adding water.

• It allows the desalination time to be selected, which is directly related to the percentage or degree of desalination to be achieved for the desired culinary application. Therefore, there is greater control over the degree of salt to be obtained.

• The application of this technique does not affect either the texture or the quality of the treated food product.

• The device is easily scalable, being able to adapt its configuration for industrial applications as well as for small household appliances for catering.

• The DILUATE compartment is modular.

INNOVATIVE ASPECTS

The main innovative aspect of this technology is the application of the electrodialysis technique to desalinate solid salted food products.

The technology has been developed at laboratory scale using salted cod as the food product to be desalinated.

Using two different conditions, the researchers obtained the following results:

• Applying a controlled current intensity of 100 mA, for a time of 120 minutes they achieved a degree of desalination of 96 % over the initial salt content of the cod piece.

• By applying a controlled potential difference of 15 V for a time of 60 minutes, they achieved a degree of desalination of 66 % of the initial salt content of the cod piece.

The research group is currently working on the development of a prototype for a restaurant. This prototype can be used to desalinate a cod loin in 4 pieces of 250 g each.

This technology has its application in the field of desalination of salted and solid food products such as: cod, salted bacon, marine sausages, seaweed, anchovies, sardines, herring, olives with excess salt, etc.

The technology could be used both at industrial level and in the catering sector.

Companies interested in acquiring this technology for commercial exploitation are sought:

• Patent licensing agreements.

• R&D projects.

• Development projects to adapt them to the needs of the interested party.

• Proof of concept projects, etc.

Company profile sought:

• Companies manufacturing industrial machinery for the food sector.

• Companies manufacturing electrical appliances for the restaurant and catering sector.

This technology is protected by patent application.

• Patent title: "Procedimiento y dispositivo para desalar un producto alimentario salado mediante un proceso de electrodiálisis".

• Application number: P202331082.

• Application date: 22 December 2023.

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959