Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Automatics, Robotics and Computer Vision group from the Physics, Systems Engineering and Signal Theory Department from the University of Alicante has know-how for the development of systems for automatic disassembling of components.

These systems are formed basically of a set of robots working in a cooperative way and helped by an artificial vision system and a trajectory scheduler. The systems allow to remove the different elements that form a product in order to its recycling.

The group is interested in establishing R&D projects with companies that need to adapt this know-how to their specific needs.

The Automatic, Robotic and Artificial Vision group from the Physics, Systems Engineering and Signal Theory Department from the University of Alicante has know-how for the development of systems for automatic disassembling of components.

With this know-how, the research group has fine-tuned a technology for automatic disassembling of components that can be adapted to the client’s needs. The technology consists on a system formed of the following elements:

- An automatic disassembling cell formed of several industrial robotic arms (usually 2) working in a cooperative way.

- A multi-sensorial artificial vision system to identify the elements of the surroundings, that is to say, the different components to disassemble.

- A knowledge base to store basic information about the components to disassemble.

- A software module of trajectory generation (schedulers). This module does the movement schedule, that is to say, the analysis and setting of the optimal trajectories that the robotic arms have to follow.

- An automatic supervision module to check if the process is done correctly, according to the directives of the movement schedule modules, or if it is done according to the foreseen parameters of the disassembling of each component. This system is necessary due to the fact that the surroundings can change at any moment.

PERFORMANCE

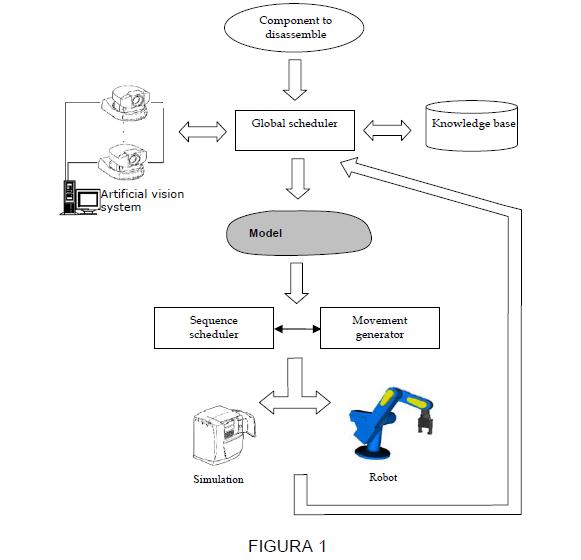

The image 1 is a sketch of the technology performance. A finished product is going to arrive to the disassembler. This product will have specific characteristics depending, first, on the kind of product it is, and second, on the way it has been used (for example, a car that is going to be disassembled may not have some part, may have another part distort, etc...). The global scheduler receive the total or partial disassembling order, in such a case the components to be disassembled must be specified.

Once the product is identified on the knowledge base, a model of it must be generated. The model is obtained thanks to the information given by the artificial vision system that allows to obtain the current product state. This is done because the product may have changed considerably with regard to what was stored in the knowledge base.

With the real model of the product, the sequence scheduler take responsibility for selecting in an automatic way the components to be disassembled so we can disassemble specifically one, and to determine the order in which each one must be removed. Everything, of course, must be done without doing more operations than we need.

The function of the movement generator module is to determine the movements that the robot has to do to disassemble a specific component, taking into account the rest of the assembly and the kinematics of the robot that will be used.

Once the movement series is generated, previous to the real automatic disassembling by means of a robotic system, we have a simulation module that allows visualizing the disassembling process. The model will be specific for each object to disassemble, and depending on the specific object everything will be done in a way or in another.

Finally, a feedback is done in the system to start the disassembling of a new component.

Nowadays, there are a lot of assembling robots, but not disassembling ones. The disassembling of components applications are not extended in a commercial level.

The automatic disassembling techniques allow to separate the different elements that conform a product for its recycling, so the disassembling process can be considered as selective, destructive when necessary and not destructive in the rest of situations.

The automatic disassembling allows the online process control and more flexibility and adaptability to the changes that appear during the same process. That is due to the incertitude that exists with regard to the product to disassemble, the maintenance state, the numerous manufacturers that are and their wide range of products.

This technology can be applied per modules depending on the client’s needs, that is to say, it is not necessary to use the complete system. This can be useful, for example, as a support for tasks planning, visual inspection, training of workers in manual disassembling, etc.

The technology is applicable for:

- Disassembling parts of vehicles.

- Recycling electronic components (PCs, mobiles, household appliances, toys with polluting elements as batteries, etc.)

- In general, all the situations where there is a need to avoid the contact between workers and components or that need robotization to process a high number of elements or to help workers.

The technology is applicable to closed systems in which several components must be disassembled systematically and the original parts do not suffer disproportionate changes.

- Partner sought: Industries.

- Sector: Any industry that needs to disassemble components for the recycling or dismantling of manufactured components.

- The research group is interested in establishing R&D projects to adapt their know-how to the specific needs of the client.

The method is protected by know-how. The research group has published several scientific articles.

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959