Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Institute of Organic Synthesis of the University of Alicante has developed a compound that allows the selective extraction of internal transition metals (lanthanides and actinides), avoiding the appearance of dangerous radioactive species.

The extracting mixture is highly efficient and selective, allowing the complete recovery of thorium with respect to uranium and other metals of the f, d and/or p blocks of the periodic table. Moreover, this mixture can be reused in new extractions without loss of effectiveness, which is a major advance in environmental protection.

This technology can be applied in areas such as nuclear chemistry, nuclear medicine and nuclear waste treatment.

Companies interested in acquiring this technology for commercial exploitation through patent licensing agreements are sought.

Nuclear power is the clean and efficient energy source most widely used worldwide to generate electricity. In fact, nuclear reactors will produce the most electricity in the future due to abundant fuel reserves and low emissions of carbon dioxide and other greenhouse gases.

Currently, the extraction of thorium, a key element in nuclear processes, can be dangerous due to the emergence of radioactive species such as plutonium. In addition, thorium extraction methods are not selective and can damage the environment.

Thorium and uranium are the only naturally occurring actinide elements in nature, but they are widely dispersed in the ores that contain them and require very selective extraction methods. Thorium is much more abundant than uranium and, unlike uranium, produces lower amounts of minor actinides and no plutonium, which simplifies long-term radioactive waste management. In addition, the thorium nucleus has the capacity to produce a uranium nucleus when it absorbs a neutron, and is capable of emitting alpha radiation, which is being applied with great success in short-range therapies such as cancers and micrometastatic diseases. For all these reasons, thorium is positioning itself as one of the most important nuclear energy sources of the future, and its consumption could increase substantially if it is commercialised for use as a nuclear fuel.

Thorium is highly diluted in rock, requiring more mining, milling and local processing at the site where it is recovered than uranium, so highly selective extraction methods are essential to ensure its extraction.

The separation of uranium and thorium from the ores containing them is of great concern to the public, as the radioactive nuclei need to be well managed. Currently, the methods used for the selective extraction of thorium from uranium do not take into account the recovery of the extracting compound, nor that of the solvent containing it, hence the need to obtain a technology that does allow for this.

In order to solve the problems described above, a TSIL (Task Specific Ionic Liquids) + IL (Ionic Liquid) extractant system has been developed that allows the selective liquid-liquid extraction of thorium from other metals belonging to the f, d and/or p blocks of the periodic table, such as uranium, without the appearance of dangerous radioactive species.

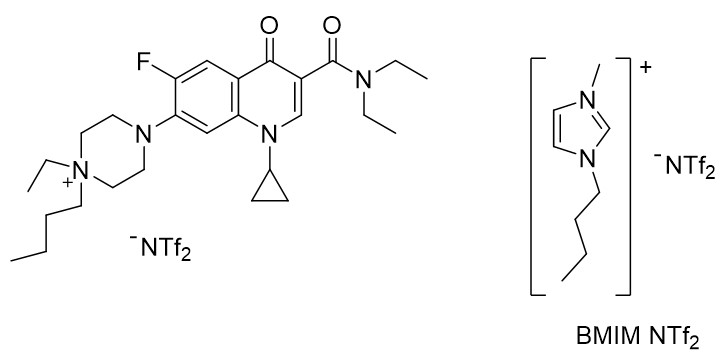

The invention is based on the preparation of an extractant mixture consisting of the compound TSIL dissolved in the ionic liquid BMIM NTf2 (see Figure 1):

Figure 1: Chemical formula of the compounds making up the extractant mixture.

The procedure for the preparation of the TSIL compound is carried out in three simple steps (under mild reaction conditions):

1. N-alkylation reaction of the antibiotic ciprofloxacin with 1-bromoethane to obtain the following intermediate compound (see Figure 2):

Figure 2.

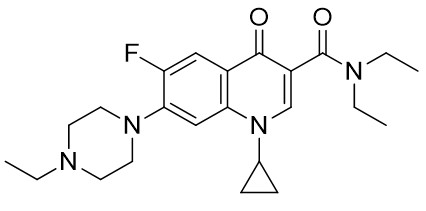

2. Amidation reaction on the previous compound using N,N-diethylamine to obtain the following compound (see Figure 3):

Figure 3.

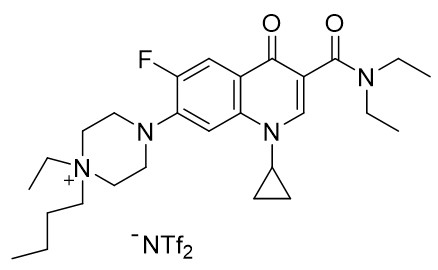

3. Alkylation reaction of the above compound with 1-iodobutane to give the compound TSIL with the following chemical formula (see Figure 4):

Figure 4.

The above chemical reactions are carried out in the presence of different catalysts under specific temperature and pressure conditions. Once the TSIL compound is obtained, it is mixed with the ionic liquid BMIM NTf2 to form the extractant composition (see Figure 1).

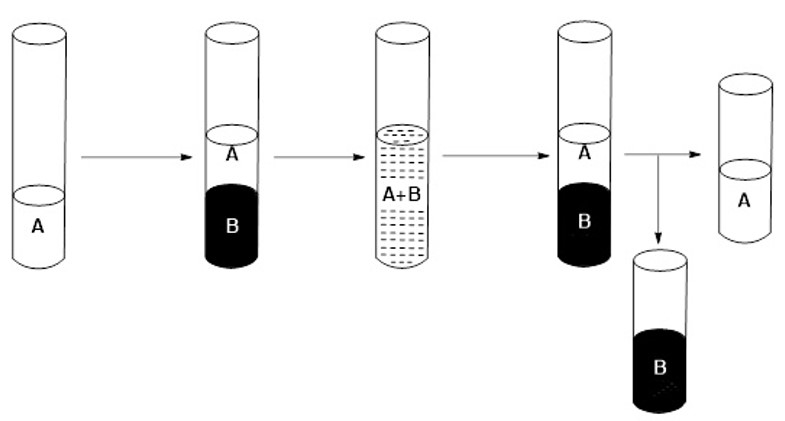

The procedure for the selective extraction of thorium from a sample containing thorium and other f-block, d-block and/or p-block metals of the periodic table is summarised in the following steps:

1) Prepare from the extractant mixture from the compound TSIL + the ionic liquid BMIM NTf2 (B).

2) Adjust the sample to be separated (containing thorium and other f-block, d-block and/or p-block metals) to pH=1 (A).

3) Add the liquid extractant mixture (B) to the liquid sample to be separated (A).

4) Shake.

5) Wait for the two solutions to separate by density difference.

6) Separate the two phases: the organic phase (B) corresponds to the extractant composition which includes the thorium initially contained in the sample to be separated (see Figure 5).

Figure 5: Selective extraction process.

7) Add to the organic phase recovered in the previous step (B) an aqueous solution buffered to pH=6 (C).

8) Shake.

9) Wait for the two solutions to separate by density difference.

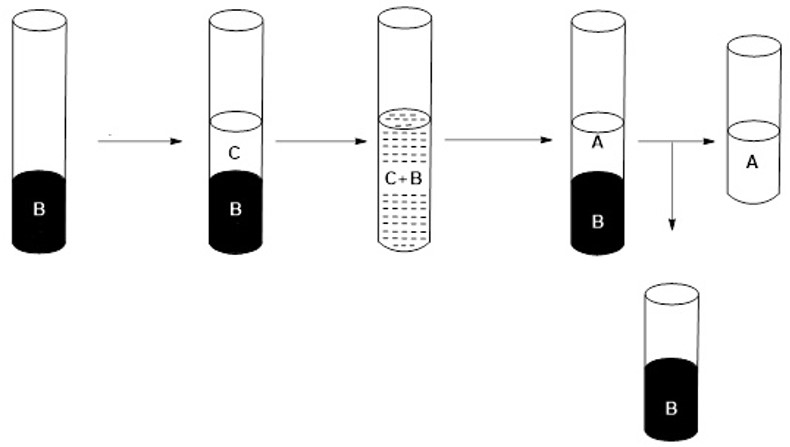

10) Separate the two phases: the organic phase corresponds to the extractant composition (B), which can be used again in other thorium recovery processes, and the aqueous phase (A) contains the extracted thorium (see Figure 6).

Figure 6: Schematic of the recovery process.

ADVANTAGES OF THE TECHNOLOGY

TSIL technology has the following advantages:

1) It allows the selective extraction of thorium against other metals belonging to the f, d and/or p blocks of the periodic table, such as uranium.

2) It is highly efficient in the selective extraction of thorium, allowing the thorium to be recovered in its entirety with a high yield due to its high affinity.

3) High specificity in the extraction of thorium from uranium and other internal transition metals (lanthanides and actinides): the rest of the metals are extracted with a low or null percentage.

4) It is possible to recover at least 95% of the extractant mixture and reuse it in further extraction cycles of thorium versus other metals.

5) The process is environmentally friendly, as it avoids the appearance of dangerous radioactive species such as plutonium, thus improving safety in nuclear processes.

6) The process is carried out under mild reaction conditions (temperature between 0ºC-25ºC and atmospheric pressure).

7) The process is feasible on an industrial scale and can be adapted and implemented to the needs of the company (the TSIL compound has a synthesis yield of 89%).

In summary, the TSIL compound is a revolutionary technology that significantly improves current thorium extraction methods by being safer, more efficient and selective. Its application in different sectors can have a positive impact on the environment and improve energy sustainability worldwide.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

The TSIL technology has several innovative aspects that differentiate it from other similar technologies on the market.

Firstly, the novel chemical composition of the extractant mixture allows the selective extraction of thorium from other metals of the f-, d- and/or p-blocks of the periodic table, avoiding the occurrence of dangerous radioactive species such as plutonium.

Moreover, its high efficiency allows the thorium to be recovered in its entirety with a high yield, and it is possible to reuse the extracting mixture in new extraction cycles, making it a sustainable and environmentally friendly procedure (there is no other extraction system of these characteristics on the market that is recyclable).

The described technology has been developed at laboratory scale (Technological Readiness Level: TRL = 4).

The tests carried out have shown very promising results: the distribution coefficient (K), which is the ratio between the concentration of the metal in the organic phase and in the aqueous phase after extraction, calculated for thorium, is 28 times higher than that of uranium, and between 25-196 times higher for the rest of the elements studied (Lu, Yb, Gd, Sm, Nd, La, Y, Ce, Eu, Sc, Pt, Sb, etc.).

These tests have demonstrated the high efficiency of the TSIL compound in the selective extraction of thorium from other metals, as well as its capacity to recover the complexed metal in its entirety.

The results obtained indicate that this technology has great potential for application in nuclear processes. Furthermore, studies on the economic feasibility of the selective thorium extraction process with TSIL have been carried out, indicating that this technology could be cost-effective and competitive compared to other existing solutions.

The main application sectors for this novel technology are:

• Mining and chemical industry: the TSIL compound has applications in the selective extraction of internal transition metals (lanthanides and actinides).

• Nuclear chemistry: TSIL technology can be used in nuclear processes for the selective extraction of thorium from other metals, avoiding the appearance of dangerous radioactive species such as plutonium.

• Nuclear medicine: TSIL technology can also be applied in nuclear medicine, as it allows a selective and efficient extraction of thorium.

• Nuclear waste treatment: the TSIL compound also represents a considerable advantage in the treatment of nuclear waste containing thorium, as thorium can be selectively recovered.

• Scientific research: TSIL technology can be used in scientific research related to nuclear processes and nuclear medicine.

Its application in different sectors can have a positive impact on the environment and improve energy sustainability worldwide.

Companies interested in acquiring this technology for commercial exploitation through patent licensing agreements are sought.

Company profile sought:

• Nuclear industry.

• Chemical industry.

• Nuclear medicine.

• Nuclear waste treatment.

The present invention is protected through patent application:

• Patent title: "Compuesto TSIL, procedimiento de fabricación y procedimiento de extracción selectiva de torio empleando el compuesto TSIL".

• Application number: P202231098.

• Application date: 22nd December 2022.

Geological and Geophysical Studies

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959