Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Institute of Water and Environmental Sciences at the University of Alicante has developed a compact system for sanitizing wastewater from neighbourhood associations, residential areas, estates, hotels, golf courses, recreational areas, or sports grounds for reuse in irrigation, ornamental fountains, heatingrefrigeration systems, refilling of cisterns, for washing cars etc.

The system is characterized by its ease of installation and maintenance, and is fully automated. It does not generate bad odours, it saves energy and is costeffective, and can supply treated wastewater for up to 500 people.

Companies interested in acquiring the system for commercial development are sought for collaboration.

The progressive depletion of our planet’s freshwater resources has stimulated a drive to develop new technologies capable of guaranteeing a constant supply of water to the population and also the long term preservation of reservoirs. In this respect, there is a large number and variety of domestic water treatment systems available today:

1. Airtight underground septic tanks into which household wastewater drains directly. If no air enters the tank, anaerobic conditions are favoured, creating bad odours and a need for periodic cleaning.

2. Total oxidation systems into which air is allowed so that organisms already in the water can decompose organic and nitrogenous material. Although performance may be acceptable, additional treatments such as microfiltration, chlorination or ultraviolet radiation are necessary for compliance with standards set by European regulations for the reuse of wastewater. Moreover, these systems are not compact and are difficult to install, maintain and operate.

3. Wastewater sanitization systems for private use are only capable of treating small volumes of water (4 to 100 residents), which makes subsequent use in garden irrigation and elsewhere unfeasible. In addition, a suction pump is required, and even though it is possible to connect a number of units in series, maintenance is cumbersome and increases the final price to the consumer. On the other hand, the storage tank for the sanitized water has a very limited capacity, operates only in a fixed range of purification, uses a stirrer with moving parts, exposes the mixed liquor to the open air and operates with a submersible pump having electrical parts, thus making the pump unreliable and prone to failure due to frequent accumulation of hair and fibre. Finally, this system is designed for installation in cellars; thus, not only is there a need for adequate room, but it also poses a biological hazard risk in case of leaks or breakage.

The following paragraph provides the technical details of the compact system that has been developed to overcome the foregoing problems encountered by the existing technologies used to treat domestic wastewater.

TECHNICAL FEATURES:

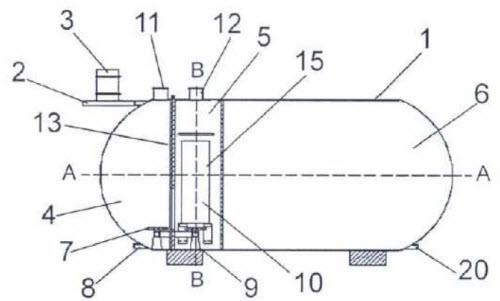

The system is based on a receptacle or tank of cylindrical configuration with dome-shaped ends, intended for horizontal burial. The inlet is equipped with a filter and there are three chambers or compartments that have been incorporated between the water inlet and outlet.

First among these is the homogenization chamber equipped with a diffuser grid and control valve for purging solids.

The second is the filtration-purification chamber, containing a diffuser grid and membrane case containing a series of polyethylene chlorate membranes.

In both cases, the diffuser grids allow aeration and agitation of the mixed liquor. In addition, they are equipped with escape ducts composed of an activated carbon filter, which acts as an outlet for the gases generated during the biological purification process. The system is also equipped with a manhole of adequate dimensions to permit workers to perform cleaning and maintenance operations. The first two chambers are separated by a sheet-metal double wall, each fitted with a removable screen of adequate aperture size to prevent coarse solids in the homogenization chamber from entering the purification-filtration chamber and damaging membranes. In this way, when one screen is removed for cleaning, the other remains in place to prevent coarse solids from reaching the membranes.

Finally, the third chamber is for the storage of treated water. It makes up most of the volume of the tank. It has an outlet to the exterior, supplying water as needed. A stainless steel sheet-wall separates this chamber and the purification-filtration chamber. View in longitudinal elevation and partial section of the compact wastewater treatment system.

View in longitudinal elevation and partial section of the compact wastewater treatment system.

THE PROCESS:

Water enters the homogenization chamber directly from a collection tank, after first having been filtered. Then, having remained there for a given residence time to undergo biological decomposition (which is promoted by the air entering through the diffusers), it passes through the screens in the double wall and enters the purification-filtration chamber, to where the membranes are located.

The system can operate under gravity or by suction using an external pump that receives treated water from a manifold connected to the membrane cartridge through a series of tubes, one for each membrane. It is also equipped with a blower for cleaning membranes (big air bubbles are created that produce tangential scrubbing). Chemical cleaning with 0.5% sodium hypochlorite is necessary when the transmembrane pressure reaches a pre-established minimum.

In addition, the system is equipped with a programmable logic controller that automatically controls all its functions, thus eliminating the need for an operator.

It has level sensors that relay information about the level in each chamber, and incorporates a GPRS for the remote control of process variables, sending maintenance alarm signals only when it is really necessary. It is also equipped with a pressure transmitter which signals when chemical cleaning may be required.

ADVANTAGES:

- It is possible to reuse wastewater originating from neighbourhoods, residential areas, estates, hotels, golf courses, in irrigation, ornamental fountains, heating-refrigeration systems, refilling of cisterns, for washing cars, etc.

- The wastewater sanitization is done “in situ”, avoiding having to pump the water to a wastewater treatment plant.

- The water obtained is of an excellent quality.

- If the treated wastewater is utilized for irrigating green spaces, it provides a distinct nutritive advantage over drinking water in that the treated wastewater contains dissolved organic and nitrogenous matter that is essential to plant growth, but in quantities that are small enough so as not to pose a risk to human beings.

- Reusing wastewater saves energy and is cost-effective.

- Using sanitized wastewater for purposes that do not require drinking water preserves freshwater resources, which is beneficial to the environment.

- A single unit can supply enough water for up to 500 people. In addition, the size of the system is such that it can be transported on all types of roads.

- The system can operate within a range of purification, depending on what the sanitized water will ultimately be used for.

- The tank is designed to be buried below ground, which saves space, minimizes odours, and makes less of a visual impact.

- It has a valve which is connected directly to the sewer system for draining when appropriate, and should it become necessary, for rapid and secure drainage.

INNOVATIVE ASPECTS:

- The system is compact (not modular), easy to install and maintain, and fully automated.

- It is designed to be buried below ground, which not only reduces its visual impact, but also the occasional generation of bad odours.

- It relies on the force of gravity for permeation, which saves energy and is cost-effective.

- It operates within a range of purification, which allows the quality of the treated water to be adjusted according to its final use.

- It is designed to prevent biological hazard risks in case of leaks or breakage.

After a number of years of investigation, a system able to supply up to 500 people has been developed, with very satisfactory results. A demonstration to view and test the system is possible under a prior agreement of confidentiality.

The compact system for the treatment of wastewater is primarily destined for use by neighbourhoods, estates, hotels, golf courses, sports centres, to reuse the treated water in the irrigation of gardens and green spaces, in ornamental fountains, heating-refrigeration systems, refilling of cisterns, for washing cars etc.

Companies interested in acquiring the system for commercial development are sought for collaboration.

Use of different forms of technology transfer is possible: patent licence agreement, assignment of use agreement, manufacture or commercialization to third party companies, etc.

The technology is protected by patent:

- Application number: P200800728.

- Date of Application: 12/03/2008.

Engineering, Robotics and Automation

Water Resources

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959