Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Molecular Nanotechnology Lab (NANOMOL) of the University of Alicante (Spain) and the Organometallic Molecular Materials Research Group from the University of La Rioja (Spain) have developed a new synthetic approach for the synthesis of black titanias with outstanding photocatalytic activity under visible light. This novel procedure is simple (one-pot synthesis), versatile and cheap (mild conditions, without the concurrence of surfactants, calcinations or high temperature steps) thereby saving cost in materials and energy.

The technology has been developed and successfully tested at the laboratory getting black titanias with excellent photocatalytic activity both in the ultraviolet, and what is more interesting, in the whole visible range, and good thermal and hydrothermal stability. These materials find application in very different areas such as the degradation of organic pollutants, DeNOx processes or as an alternative to the Grätzel solar cells.

The technology is protected by a Spanish patent application and the group is looking materials producing companies interested in acquiring the technology for commercial purposes, or to establish partnerships for the development and industrial scale, or companies interested on testing the materials for photocatalysis, solar cells or environmental applications.

Titanium dioxide, also known as titania, is one of the most widely used semiconductors photocatalysts in water/air purification, hydrogen production from water splitting, pollutants elimination (VOx and NOx) and high-efficiency dye-sensitized solar cells (DSC). Titania has many advantages: it is cheap, abundant, non-toxic, chemically stable, and biocompatible, and is widely used in health care products as well as in paints. However, TiO2 overall efficiency for solar-driven photocatalysis is very limited, because of its large band gap (3.2 eV for anatase phase) which corresponds to the UV light range (380 nm anatase phase) which accounts for less than 5% of the total solar irradiation. Therefore, significant efforts are being conducted to reduce its band gap to the 400-900 nm spectral range (visible and near-IR), but the results are so far from the market requirements.

So, there is an urgent need for a new and disruptive technology based on a simple and cheap synthesis methodology which will allow for the engineering of the band gap of semiconductors to fully utilize the visible light range, giving these promising photoactive materials a commercial opportunity.

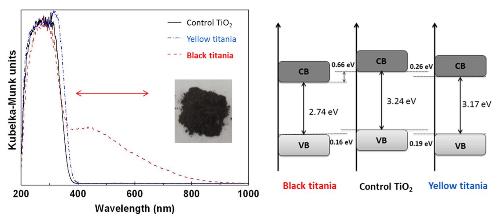

Fig 1. DRUV spectra (up) and schematic illustration of the density of states, DOS, (bottom) of black titania (in red) in comparison with the control titania (in black) and with one yellow titania also synthesized by our groups (in blue)

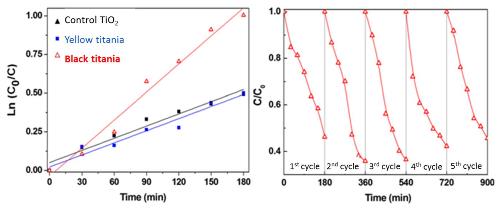

The black titania exhibited enhanced photocatalytic activity under UV and visible light in the Rhodamine 6G degradation reaction under both UV and visible irradiation (TOC measurements confirmed degradation towards CO2), Fig. 2, left. Recycling tests under the same conditions prove the stability of this hybrid titania (Fig. 2, right). This new photocatalyst has been recently tested indicating very good NOx degradation values with high selectivity towards nitrates when tested in a road. This material constitutes the only example on the use of polymetallic titanium alkoxides as organotitania precursors for the synthesis of stable and visible-light active titanias.

Fig 2. Photocatalytic activity and recycling tests under the same conditions in the degradation reaction of an aqueous solution of R6G (5*10-5 M) under visible (400 W) irradiation

The technological potential of these hybrid titanias covers areas ranging from photocatalytic splitting of water for hydrogen production or purification of water/air to dye-sensitized solar cells or materials for example, for self-cleaning applications.

ADVANTAGES OF THE DEVELOPED TECHNOLOGY

• The proposed synthetic method is very simple, versatile and can be carried out at low temperature and pressure, avoiding the use of hazard conditions, such as hydrogen or ammonia at high temperatures, with the consequent saving.

• Our black titania is able use the whole UV and visible range of solar radiation showing a really high photocatalytic activity and thermal stability with an increase of only 0.6% in the production cost in comparison with control titania.

• Crystal disruptors are incorporated into the bulk of the semiconductor which greatly protects them (avoiding the problems associated to the stability of the dye) and improves the electronic transference of the charge-transfer dye.

• Band gap control is carried out by crystal engineering instead of the traditional band gap engineering based on chemical methods (i.e. doping and hydrogenation) diminishing the charge-recombination probability.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

• The titania is black, and then absorb in the whole visible range (band gap 2.74 eV) and maintains its photocatalytic activity at least after 5 cycles reaction with an efficiency of 95 %.

• The synthesis process is simple, inexpensive and versatile (a wide variety of functional compounds can be incorporated in the structure of the titania lattice avoiding blocking the mesoporosity and maintaining the anatase structure).

• Excellent thermal and hydrothermal stability. The functionality is incorporated into the structure of the titania being protected thereby.

The technology has been developed and successfully tested at the laboratory. The results of the different tests have demonstrated the effectiveness of the synthesis process and the good properties of the obtained functionalized titanias. This technology is available for demonstration – field tested.

• Photocatalysis. Companies producing photocatalytic materials.

• Solar panels. Companies producing materials for solar panels for the enhancement of its efficiency.

• Materials degradation of contaminants in soil, water or asphalt.

Pollution and Environmental Impact

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959