Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Engineering Design and Technological Development (DIDET in Spanish) group from the ArtefactosLAB laboratory of the University of Alicante has developed a pelvic seat that can be moulded on the patient, in a comfortable, fast and economical way for the patient and which reduces the number of professionals involved in the manufacturing process.

This device, manufactured by 3D printing, allows the appropriate postural control for a correct physiological development of children with motor functional diversity, which allows them to perform daily seated activities.

The group is looking for companies or institutions interested in continuing with this work of social innovation by developing the device or in the design and manufacture of new ones.

Professionals working in the field of paediatric neurorehabilitation often find that most of the children they treat have difficulties in remaining in an independent and functional sitting position for different reasons.

Nowadays, there are technical aids that represent an important improvement in the sitting position of people with motor functional diversity. These devices provide greater stability to the patient in that position, which gives them the opportunity to raise their head and to be able to free their upper limbs and use them in functional activities such as playing, painting or eating, both at home and in the educational or community environment. At the same time, however, there are a number of disadvantages:

a) On the one hand, there is the handmade plaster seat of low material cost but of complex modelling and difficult optimal result, given that it requires the coordinated work of a minimum of three therapists keeping the child in the appropriate quadrupedal posture modelling the plaster on his/her body. In addition, there are children with whom it is very difficult to make a traditional plaster cast, because they do not cooperate or show involuntary movements.

b) On the other hand, the orthopaedic pelvic corset or pelvic seat has a high price, added to the time it takes to make it. When they are customised, the user must maintain a quadrupedal posture, otherwise, when they are prefabricated, the seat is incorrectly adapted to the child.

Despite the incursion of 3D technologies in the manufacture of orthopaedic pelvic seats, the procedure for obtaining them has not been improved, and they are all based on the same sequential process: obtaining the negative of the mould; obtaining the mould of the seat (in the case of the handmade one, drying time of the plaster on the patient) and post-finishing of the seat, in which the ergonomic material or sanitary EVA is added to avoid direct contact of the seat on the skin, as well as belts and/or support systems if necessary. This is a very extensive obtainment process, with the intervention of different specialists, which makes the construction of the pelvic seat costly in both time and price.

In all cases, a phase is required prior to or during the manufacture of the seat in which the patient must remain in an uncomfortable posture, aided by supporting and/or elevation elements and several therapists.

For all of the above reasons, it is necessary to design a pelvic seat that can be moulded on the patient, in a comfortable, quick, economical way for the patient and which reduces the number of professionals involved in the manufacturing process.

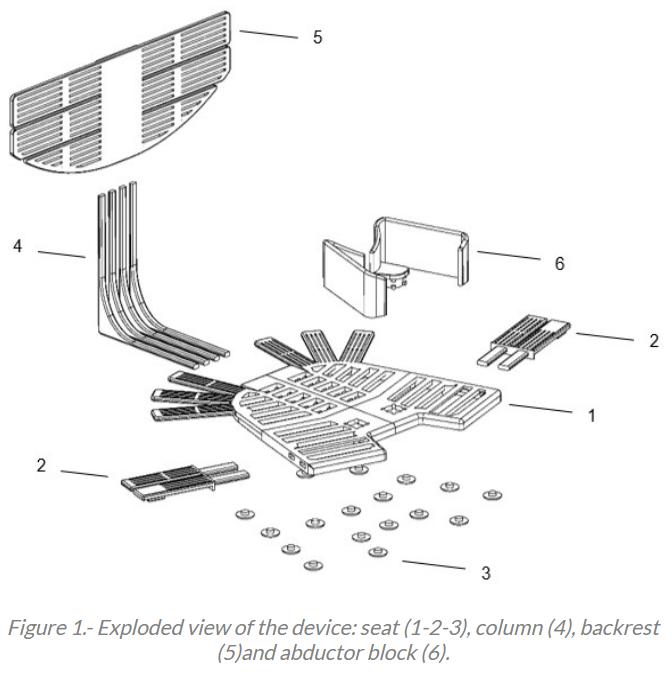

The device consists of four main parts (see Figure 1): seat, column, backrest and abductor block.

• The seat allows adaptation to the morphology of the patient's body by direct modelling in a simple and safe way; it is also the base on which the assembly is mounted.

• The column is made up of a set of angular-shaped beams arranged in parallel. Its main function is to mechanically join the seat and backrest, giving the whole unit stability and strength. Thanks to the 3D manufacturing system, the angle formed by the column can be customised to adapt to the needs of the patient and, therefore, to the type of active or passive seat (between 90º and 120º) required, even with the possibility of being interchangeable.

• The backrest, like the seat, can be adapted to the morphology of the patient's back by modelling it directly on the patient. This part is the main support for the patient's back and therefore ensures stable support for the upper trunk. On the other hand, this part is variable in height, it will gain in height depending on the patient's need for postural control.

• The abductor block allows the seat to adjust as much as possible to the patient's pelvis and thus prevents the patient from sliding forward.

As for the manufacturing process of the seat and backrest, it is optimised to two single phases: first, they are prefabricated with 3D technology, more specifically, they are built flat (unfolded) and surrounded perimetrically by a series of strategically placed elongated rectangular tabs; and then they are moulded on the patient.

Consequently, this device makes it possible, on the one hand, to mould with simple tools such as a hair dryer, which is easily accessible; and, on the other hand, the patient does not have to remain immobile in uncomfortable positions for long periods of time as occurs in the production of plaster seats, also avoiding uncomfortable sensations.

It is recommended that this whole process be carried out or supervised by a specialised therapist.

It is an adaptable and evolving pelvic seat, since in short periods of time, especially in the case of pediatric patients, it is necessary to obtain several pelvic seats in a short space of time (caused by their own growth and changes in clinical and/or day-to-day needs), with the developed device it is possible to re-conform the critical parts of the pelvic seat to adapt to growth or clinical changes as many times as necessary, adjusting to the patient's body and the needs specified, with minimal impact on the patient and in a few minutes.

In addition, it is important to emphasise the portability of the seat, justified by its light geometry, low weight thanks to the lightness of its materials, its quick installation on any chair or surface by means of non-invasive fastening systems and its non-slip system. If required by the patient, the ergonomics and comfort of the seat can be improved by attaching comfortable material to the inside of the seat.

In addition, the seat includes in one of the front sides a housing that corresponds to a universal 90º turn locking system for interchanging the user's personal aid accessories, which have the same universal 90º turn locking system incorporated, so that they can be housed in it, for example, an accessory device for a bottle, pencil or glass of water, allowing certain elements to be within the user's reach while carrying out other activities or movements, even with difficulties in the mobility of one or both upper limbs, minimising the external aid of another person.

The material in which the seat and backrest are made is rigid and mouldable, allowing it to adapt and reconform to the physiognomy of the body, and, as soon as it cools, it stabilises the patient's posture. As for the spine and the abductor block, it is made of materials with a high resistance to pull and tear strenghts, providing stability and resistance to the whole.

In detail, the clinical problems solved by the use of the seat, and the objectives sought by the pelvic seat are:

• General:

o Control the progression of musculoskeletal deformities.

o To reinforce the therapeutic objectives.

o To improve postural control.

o Minimise abnormal reflexes, postures and tone.

o Postural adjustment training.

• Specific:

o Avoiding the kyphotic position that they tend to acquire with incorrect postures that they adopt.

o To avoid possible alterations at hip level, such as dislocation.

o To leave the upper limbs free to manipulate, discover their environment or play, as they do not have to control their base of support with them.

o Ensure that the patient sits in such a way that the weight of their body is symmetrical on both sides of the pelvis.

INNOVATIVE ASPECTS

Both the design and the manufacturing process of the pelvic seat have been optimised so that it can be produced using a 3D printer which, together with the use of three-dimensional models, has become an alternative manufacturing process to the conventional one. Its application within assistive technologies opens up endless possibilities for improving the quality of life of people with functional diversity, mainly due to four factors:

• Low cost of materials and equipment needed.

• Speed of manufacture.

• Freedom of design that allows to approach the personal and intrinsic needs of the user, going beyond the clinical needs (on which the conventional prosthetic production sector focuses due to issues of final costs and number of units).

• Potential worldwide manufacturing, giving the user or rehabilitation professional the possibility of self-manufacturing and customising their own device, which also means savings in logistics and distribution.

The current prototype is the result of the participation of different people with motor functional diversity with whom the dimensions and performance of the pelvic seat have been tested and adjusted. It is therefore a device that perfectly fulfils the intended objectives.

It is mainly aimed at the assistive technology sector and improving people's quality of life and, more specifically, at the field of pediatric neuro-rehabilitation.

3D printing or additive manufacturing is a technique that can be applied to satisfy any need, in any field, that a person may have. It is especially useful for people with functional diversity with very personal problems in fields such as medicine, education, work or mobility.

From ArtefactosLAB, the DIDET group is looking for companies or institutions interested in supporting the development of the pelvic seat or in the design and manufacture of other new devices for social purposes.

This technology is protected by a utility model application:

• Title of the utility model: "Asiento pélvico termoconformable directamente sobre el paciente "

• Application number: P202130680

• Date of application: 16/07/2021

Engineering, Robotics and Automation

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959