Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

Polyurethane adhesives are widely used in industry for bonding materials in the footwear, electronics, renewable energy, aeronautics, and construction industries, as well as in composite materials. However, they have limitations due to their mechanical properties and stiffness.

Researchers at the university have developed a process to add different graphenic carbon materials to polyurethane adhesives in a very small amount (less than 0.1% by weight). In this way an adhesive with improved thermal and mechanical properties (mainly toughness), and notably increased adhesion properties have been obtained.

The resulting adhesives have been tested for verifying their new properties. These properties are ideal for use in high performance applications, such as in the electronic components industry.

The use of waterborne and 100 % solids polyurethane adhesives is widespread in industry when excellent adhesion characteristics for different applications are needed. However, in certain applications high thermal and mechanical properties of the polyurethane adhesive without deterioration of the adhesion properties are required. In order to achieve these properties, inorganic materials such as silicas or nanoclays are usually added in amounts between 5 and 20 wt%. This solution has the disadvantage of increasing the viscosity, generating the sedimentation of inorganic particles and producing excessively rigid and fragile solid polyurethane films, this limiting the performance of the polyurethane adhesives.

Another solution consisting in the addition of carbon materials, such as carbon fibres, carbon nanotubes and carbon blacks, to the polyurethane adhesive has been considered. However, this solution also presents several limitations derived from the low toughness of the solid films and the high amount of additive required.

The invention developed by researchers at the University of Alicante is based on the addition of small amounts of graphenic carbon materials. This group of materials includes graphene and graphene nanoplatelets, graphene oxide (GO), milled graphite and graphene nanofibers.

There is evidence from different studies that the addition of the graphenic carbon materials improves the mechanical and thermal properties as well as the conductivity of polyurethanes. These studies do not reflect the effect that is produced on their adhesion properties. In addition, most of the previous developments have required the functionalization of the graphenic carbon material and the amounts to be added to the adhesive in all cases exceeds 0.10 wt%.

The materials developed by the researchers allow the improving of the limitations of the previous developments. This material consists of a polyurethane adhesive that incorporates non-functionalised graphenic carbon materials, in a percentage lower than 0.10% by weight, in which the adhesion and tenacity properties are substantially improved without increasing the viscosity. The new polyurethane adhesive has also very adequate thermal, mechanical and conductivity properties.

The manufacturing process stands out for the reduction of steps since it is not necessary to functionalize the graphenic carbon materials or the use of ultrasounds to disperse the graphenic carbon materials into the adhesive, irrespective if it is waterborne or 100 % solids adhesive.

A process of synthesis of polyurethane adhesives with graphenic carbon materials has been developed for the following types of adhesives:

• Solvent-free polyurethane adhesives (100 % solids)

• Organic solvent-based polyurethane adhesives

• Waterborne polyurethane adhesives.

For its elaboration the following common stages to the three types of adhesives are developed:

1. Addition of the graphenic carbon material during the synthesis of the polyurethane adhesive.

2. Synthesis of a prepolymer.

3. Addition of a chain extender.

In the case of waterborne polyurethane adhesives, an additional stage is added due to phase inversion.

A wide variety of graphenic carbon materials have been tested under a variety of conditions. The results obtained from the tests have allowed to obtaining an important know-how on the influence of each of the graphenic carbon materials and the synthesis conditions on the properties of the resulting polyurethane adhesive.

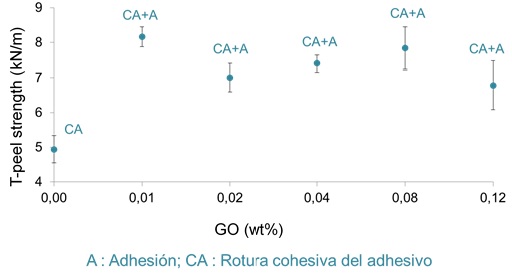

• Significant improvement in the adhesion properties of the polyurethane adhesives.

• The resulting adhesive has excellent thermal, mechanical and conductivity properties, as well as improved toughness.

• Minimum amount of graphenic carbon material (less than 0.1% by weight) is needed. In the state of the art there are some examples of the addition of graphenic carbon materials to adhesives but in no case in such a low proportion.

• The addition of graphite oxide (GO), milled graphite (MG) or graphite or grapheme nanoplatelets (GNP) does not require the use of ultrasounds to disperse into the polyurethane adhesives.

• Non-functionalised graphenic carbon materials are used. Until now, most of the previous studies in polyurethanes require the functionalization of the graphenic carbon material.

• The viscosity and color of the polyurethane adhesive are not altered by the addition of graphenic carbon material (less than 0.1% by weight).

In industry there is a need to use polyurethane adhesives with improved adhesion properties that also impart toughness to the adhesive joints made with them.

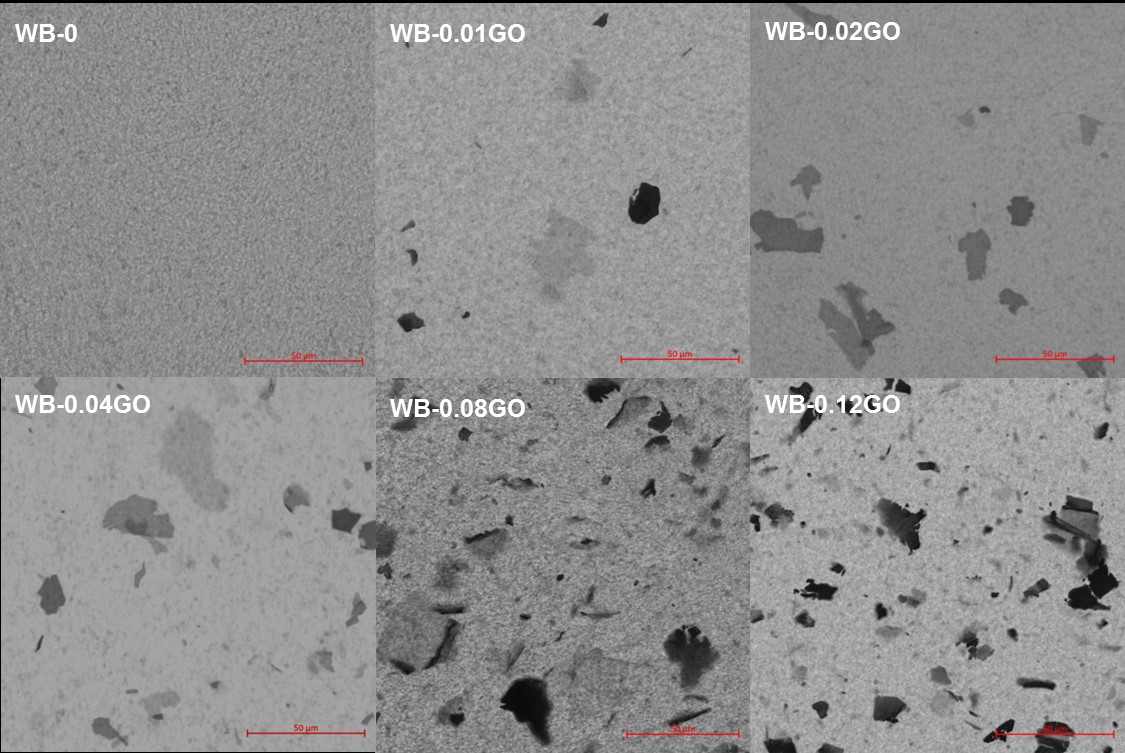

Until now, the use of graphenic carbon material as an additive to polyurethane adhesives had not been studied in depth and their influence on their adhesion properties was unknown. The work developed by the researchers has allowed the development of a process to obtain different polyurethane adhesives with significant improvements in their adhesion and mechanical properties with the addition of a minimum quantity (less than 0.1% by weight) of graphenic carbon material. These improvements are related to the excellent dispersion of the graphenic carbon nanoparticles in the polyurethane matrix (Figure 1).

The manufacturing process has been carried out satisfactorily at the laboratory level where the combinations of components and synthesis processes have been optimised.

Different polyurethane adhesives have been developed by combining different graphenic carbon materials. These adhesives have been synthesized by means of different solvent-free procedures (100% solids), in organic solvent base and in aqueous base.

These adhesives have been analysed and tested, obtaining satisfactory adhesion and toughness.

This type of adhesives has a wide variety of application fields. It can be used in the joining of different materials where adhesion requirements are high and also requires high performance in terms of thermal, mechanical (particularly toughness) and electrical properties.

Among its fields of application are their use in the manufacture of electronic components, energy storage devices, gas purification systems, etc.

Researchers are looking for partners to negotiate patent licensing agreements, as well as to develop R&D projects that allow the development of specific adhesives adapted to the specific needs of companies.

This technology is protected by patent application.

• Patent title: "Polyurethane adhesives improved by the addition of graphical carbon materials".

• Application number: P201830167

• Date of application: 23/02/2018

Construction and Architecture

Pollution and Environmental Impact

Pharmacology, Cosmetics and Ophthalmology

Engineering, Robotics and Automation

Toys

Wood and Furniture

Materials and Nanotechnology

Medicine and Health

Stone and Marble

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959