Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Design in Engineering and Technological Development (DIDET) group from the ArtefactosLAB laboratory of the University of Alicante has developed a functional rehabilitation handle that improves the manipulative skills of patients with neurological and/or physical disorders, promoting an increase in their autonomy in basic activities of daily living. This device, manufactured by 3D printing, offers great advantages in terms of functionality, intelligent design and affordable cost for everyone.

The group is looking for companies or institutions interested in continuing this work of social innovation by developing the device or in the design and manufacture of new ones.

The methods used for clinical assessment are normally limited to the evaluation of grip strength with a dynamometer, an instrument that allows the measurement of maximum grip strength in a limited time interval, and it is not possible to translate the data of maximum force exerted as a predictor of the manipulation of everyday objects.

Other devices on the market, which aim to train hand strength, are electronic dynamometers capable of connecting via Bluetooth to a mobile application, where the patient can obtain "in situ" feedback of the force being exerted, but they do not allow any basic or instrumental activity of daily life to be performed. Another option is robotic devices, which are more expensive.

The problems of the existing options on the market are the inability to measure force in real time and the versatility in the activities that the patient can do during therapy, being impossible to perform basic and instrumental activities of daily living at the same time as training force modulation, all this using a device that is feasible in terms of manufacturing, thus making it more affordable to all audiences.

For all of the above reasons, it is necessary to design a functional rehabilitation handle that solves the problems raised here.

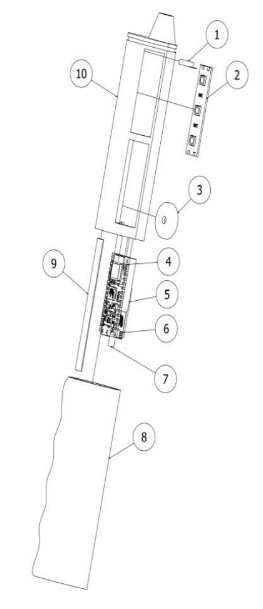

The proprioceptive functional rehabilitation handle comprises the following elements (see Figure 1):

• Housing (8) consisting of an ergonomic casing where the rest of the handle elements are pressed in.

• Sensor (9) capable of measuring force or, failing that, deformation.

• Base (10) where the tool to be used is inserted, consisting of a compartment where the electronic elements of the handle are inserted, which are as follows:

o Vibrating motor (1) used for the vibrotactile stimulus.

o LEDs (2) to indicate the force exerted.

o Piezoelectric buzzer (3) used for the sound stimulus.

o Microcontroller (4) to store the instructions in its memory.

o Battery (5) to achieve an autonomous device.

o Electronic module (6) to control the battery charge.

o On/Off switch (7) to turn the device on and off.

In this way, the invention presents the capacity to measure the strength in real time and the versatility in the activities that the patient can do during therapy.

Figure 1: View of the device with its respective elements

MAIN ADVANTAGES OF THE TECHNOLOGY

This device has a number of outstanding advantages:

• It has been manufactured as an ergonomic handle of flexible material in order to facilitate the distribution of the gripping force and provide comfort during use.

• Thanks to the material it is made of, it is easy to clean and disinfect and is waterproof. In this way, it is possible for any user in daily life to use the handle during different activities, regardless of the environment in which they are carried out.

• At the same time, it has a coating that makes the device resistant to shocks and splashes.

• It integrates pressure sensors that make it possible to measure the force exerted by the patient during an activity in real time and constantly, the variations and reactions of the patient are recorded thanks to a communication system between the device and the application. In this way, it provides the patient with biofeedback of 3 types when he/she exerts a grip force that is not adapted to the requirements of the activity:

o Optical

o Auditory

o Proprioceptive

By generating the warnings, the patient modifies his or her pressure force and learns, by experimenting with his or her own movement, which force to exert.

• Connectivity, the device connects to a multiplatform application. This application allows it to be adapted according to four different profiles (professional, patient, carer and administrator) depending on the different uses of the device and the rehabilitation environment.

• Interchangeable heads to train grip strength during different basic and instrumental activities of daily life such as eating or brushing teeth (see Figure 2). All this information is stored in the application and the data generated during the use of the device is interpreted.

Figure 2: Prototype of the device with eating head

• The device can be formatted (deleting the data of the patient who has been discharged) and can be used individually and/or consecutively by another patient collecting information on their progress.

• It allows rehabilitation at home with or without the physical presence of the therapist and avoids the need to travel, enhacing time flexibility and agility in the sessions of patients who come to the clinic in person.

INNOVATIVE ASPECTS

Both the design and the manufacturing process of the device have been optimised so that it can be produced using a 3D printer which, together with the use of three-dimensional models, has become an alternative manufacturing process to the conventional one. Specifically, a fused deposition modelling (FDM) machine has been used. Its application within rehabilitation technologies opens up endless possibilities for improving the quality of life of people with functional diversity, mainly due to four factors:

• Low cost of materials and equipment needed.

• Speed of manufacture.

• Freedom of design that allows to approach the personal and intrinsic needs of the user whatever their age or pathology, therefore, going beyond the clinical needs (on which the production sector focuses for reasons of final costs and number of units).

• Manufacture anywhere in the world, giving the user or rehabilitation professional the possibility of self-manufacturing and customising their own device, which also means savings in logistics and distribution.

Consequently, this innovative device represents a new socially responsible product that generates a positive social, environmental and economic footprint in the community. The result is a product that is soft to the touch and durable thanks to the manufacturing material.

The current prototype is the result of the participation of different people with functional diversity with whom the performance of the rehabilitation handle has been tested and adjusted. Therefore, it is a device that perfectly meets the intended objectives and can be obtained through additive manufacturing, with the capacity for customisation according to the user's requirements.

Mainly, it is aimed at the sector of technologies for rehabilitation and improvement of people's quality of life and, more specifically, at the field of neurorehabilitation.

3D printing or additive manufacturing is a technique that can be applied to satisfy any need, in any field, that a person may have. It is especially useful for people with functional diversity with very personal problems in fields such as medicine, education, work or mobility.

From ArtefactosLAB, the DIDET group is looking for companies or institutions interested in supporting the development of the rehabilitation handle or in the design and manufacture of other new devices for social purposes.

This technology is protected by patent application:

• Patent title: “Mango propioceptivo de rehabilitación funcional”

• Application number: P202131177

• Application date: 20/12/2021

Engineering, Robotics and Automation

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959