Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The Institute of Chemical Process Engineering of the University of Alicante has developed a machine that makes it possible to manufacture filters capable of trapping 60% of the nicotine and tars present in tobacco smoke, as well as a large part of the rest of the toxic and carcinogenic compounds.

The process used is fully automated, very fast, environmentally friendly and produces very economical and efficient filters for RYO, MYO and conventional cigarettes. Scientific experiments carried out in the laboratory confirm the excellent results of this new filter concept that protects the health of smokers.

The technology is patent protected. We are looking for companies interested in acquiring this technology for its commercial exploitation worldwide.

Tobacco smoke contains more than 8.000 chemical compounds, many of which are considered toxic and/or carcinogenic. For this reason, tobacco consumption represents a major public health problem worldwide, but it is also a major business, which involves a conflict of sociological, political, economic and scientific interests.

In order to minimise this problem, different approaches are being addressed, such as: reducing the toxicity of tobacco smoke, reducing inhaled doses, developing substitute products, establishing legal limitations on additives, emissions and even tobacco use.

The constituents of cigarettes (paper, additives, tobacco, filters...) have been studied, self-extinguishing papers have been developed, genetic modifications have been made to the tobacco plant to reduce the generation of nicotine and tars, additives or catalysts have been used to reduce the emission of toxic products, special mouthpieces and filters have been designed and manufactured, the hydrodynamics of filtration have been studied in depth, etc.., but the common feature of all of them is that none of them is economically viable, so they have failed to reach the market. Therefore, the problem remains unsolved and new solutions need to be developed.

In order to solve the problems described above, a machine has been developed to manufacture filters capable of reducing nicotine, tars and toxic compounds in tobacco smoke in a very efficient way.

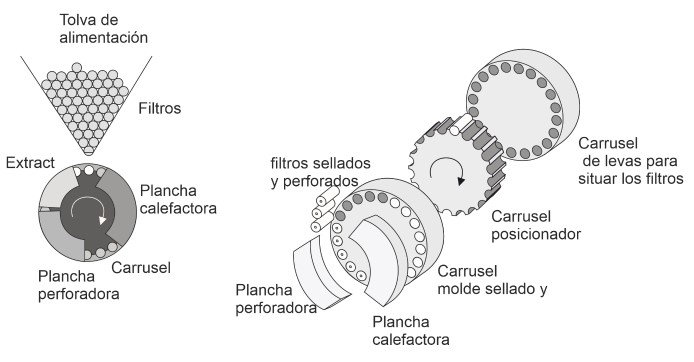

This novel machine (see Figure 1) can be configured in a number of different ways, including:

• A carousel that rotates on itself and contains a set of housings or moulds where the fibrous membranes are received.

• A plate that can be moved by mechanical means (spikes, etc.), laser radiation or any other process (cores, inserts, etc.) to optimally perforate a certain section of the watertight membrane adhered to the fibrous membrane.

• Elements for inseparably sealing the watertight membrane with the fibrous membrane, such as: heating elements, elements for dispensing waterproof or semi-impermeable sealing films, drying elements, pressure sealing elements, etc.

• An inverted pyramidal hopper containing the fibrous membranes and dispensing them through a lower opening into the semi-cylindrical housings of the carousel.

• Extraction elements (suction cups, negative pressure elements, pusher rods, etc.).

• Cutting elements.

• Control elements.

Figure 1: Schematic and basic details of the machine.

The procedure for manufacturing the filter to reduce nicotine, tars and toxic compounds in tobacco smoke comprises:

a) Placing fibrous membranes (cellulose acetate, etc.) in the rotating mould.

b) Inseparably sealing the fibrous membrane with an airtight membrane at at least at one end (or at both ends) of the fibrous membrane. Sealing can be done by:

- Impregnation of a sealing film with adhesive and waterproofing properties (e.g. cellulose acetate dissolved in a suitable solvent, polyhydroxybutyrate, polylactic acid, guar gum, starch, waterproof paints, etc.) at one end of the fibrous membrane, thus forming the watertight membrane.

- Intimate contact of a heating element (capable of up to 300°C) with the sealing membrane until it is inseparably sealed to the fibrous membrane.

- Intimate contact of a heating element (capable of reaching 350ºC) with the fibrous membrane to melt and seal that end, thus forming a watertight membrane that would be inseparably bonded to the fibrous membrane. In this way, the step of placing the watertight membrane in the mould is omitted.

- Pushing a rod that allows to join, by means of pressure, the watertight membrane (containing an adhesive film at its end) with the fibrous membrane.

c) Drilling at least one hole in the sealing membrane. Work has been done to optimise the value of the free cross-section, since the perforation cannot be of any diameter or length, as increasing either of these magnitudes decreases its effectiveness.

The fibrous membrane can be of variable length, so that, using elongated membranes, many filters can be manufactured quickly and automatically by simply cutting away portions of the fibrous membrane once the watertight membrane has been sealed to it and perforated. It can also be presented as a weakened section for the user to cut through with his own means.

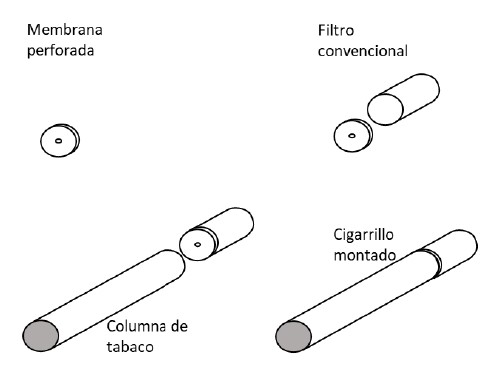

The filter manufactured according to this process consists of a primary membrane in intimate contact with the end that is furthest from the tobacco smoke column, and consists of a disc of impermeable or semi-permeable material of cylindrical shape, with a maximum thickness of 5 mm, and perforated by at least one hole passing through it perpendicular to the primary membrane section (see Figure 2).

Figure 2: Final arrangement of the membrane and filter in the cigarette.

ADVANTAGES OF THE TECHNOLOGY

The main advantages of this new technology are listed below:

1) It is very economical to manufacture these filters.

2) The process can be fully automated, which significantly increases production capacity.

3) The manufacturing process is very fast.

4) The materials used are environmentally friendly.

5) The raw materials used are commercially available and readily available.

6) The resulting filters are very effective (they reduce between 60-75% of nicotine and tars, among other toxic compounds).

7) The pleasant sensation of the smoking process is maintained (the flavour does not change, nor does the number of puffs increase).

8) The membrane is inseparable from the filter, which is very convenient for the user.

INNOVATIVE ASPECTS OF THE TECHNOLOGY

1. There is no commercial equipment on the market capable of automatically producing such filters that protect the health of smokers.

2. The machine allows several stages of the production process to be carried out simultaneously, which significantly increases the production capacity of the filters and they can be mass-produced.

3. This innovative technology can be easily implemented in the production of conventional filters and cigarettes.

The technology has been developed on a laboratory scale. For this purpose, several smoking experiments have been carried out with 3R4F tobacco from the University of Kentucky. The conditioning and smoking conditions described in the ISO 3308 standard were used for both reference cigarettes and those using the different filter membranes described above.

The gases obtained were analysed, as well as the composition of the condensed matter in Cambridge filters downstream of the filters studied (corresponding to the tars that would be inhaled by the smoker).

Experiments have been carried out with membranes made of different economical and sustainable materials, all of which have provided excellent results.

In all cases, 15 cigarettes have been smoked according to ISO 3308 specifications, and all samples have generated lower pressure losses than specified.

In addition, significant tar condensation occurs immediately downstream of the orifice (irrespective of the procedure used to obtain the filter with the perforated sealed membrane).

In any case, the end of the conventional filter in contact with the smoker is considerably less dirty than in the case of not using the perforated membrane. The perforated membrane has generated a reduction between 60-75% in nicotine and tars compared to using a conventional filter.

A prototype is currently available for demonstration.

The present invention is related to the tobacco sector, specifically, to the manufacture of filters for use in:

• RYO (Roll-Your-Own) type cigarettes.

• MYO (Make-Your-Own) cigarettes.

• Conventional cigarettes.

Companies interested in acquiring this technology for commercial exploitation are sought:

• Patent licensing agreements.

• Development of new applications.

• Agreements on technology and knowledge transfer.

Company profile sought:

• Manufacturers of filter machines for conventional cigarettes.

• Manufacturers of filter machines for rolling tobacco.

• Manufacturers of punching machines for the tobacco industry.

This invention is protected through a patent:

• Title of the patent: "Máquina, procedimiento de fabricación y filtro reductor de alquitranes y compuestos tóxicos del tabaco ".

• Application number: P202230913.

• Application date: 24th October, 2022.

Materials and Nanotechnology

Medicine and Health

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959