Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group “Procesado y Pirólisis de Polímeros” of the Chemical Engineering department in the University of Alicante has developed a novel process to recycle different types of plastic (EVA, polyethylene, polypropylene, polyurethane, foams, rubber or any kind of combination of them). The method can convert these materials into products for different sectors and applications, in an easy and economical way.

The researchers are seeking companies interested in licensing this technology and put it in the market.

The manufacture of items from microcellular materials like copolymer foams of ethylene and vinyl acetate (EVA), polyethylene (PE), polypropylene (PP), polyurethane (PU), rubber, etc. is a difficult task due to the shape and size of these materials.

The processes normally used for this kind of materials are extrusion, press of solid materials, rotational moulding and injection. In any case it is necessary to plan a sequence of reticulation and foaming processes. In that sequence the heat transmission is the main mechanism and it controls the chemical reaction. All of these processes used to have a high percentage of waste and rejected pieces due to the high complexity of the processes. This situation is making a loss in this industry.

The aforementioned materials are thermostables and they can’t be conformed by heat. It is necessary to recycle these products but it has some disadvantages:

• These materials are inert (they don’t interact easily with other materials).

• They have high specific volume and low density. It involves a high cost in collection and transport activities.

• The normal recycling processes aren’t able to absorb the high quantity of waste generated.

• They are a heterogenic group of materials so it is very difficult to process them. There are a lot of problems with the control of the process.

• The recycling process is very long and expensive.

All of these reasons make necessary to develop a new system to recycle these complex materials and take advantage of their characteristics and properties. In this way, the new process proposed by the Spanish research group contributes to this objective. It consists of the addition of conductive materials to the plastics and the use of microwaves. It supposes a cheap and fast solution to the recycling problem of these thermostables materials.

It has been developed a new procedure to obtain polymeric foams for different applications using plastic wastes like EVA, PE, PP, PU, rubber or any kind of combination of them. This procedure is very easy, cheap and fast. It comprises several steps:

1. A thermoplastic polymer is mixed with a microwaves absorbent agent (iron, manganese or zinc ferrite). The ferrite dispersed in the mixture captures microwaves and it transmits the necessary heat to obtain the foam.

2. The plastic wastes to recycle are added to this mixture (in grain or powder).

3. The mixture is heated in a microwaves oven during a certain period of time at a fixed power.

4. After the treatment with microwaves the mixture is placed in a transparent mould made of glass, Teflon or high density polyethylene. This mould is resistant and can be reused several times.

5. The obtained piece must get cold to ambient temperature.

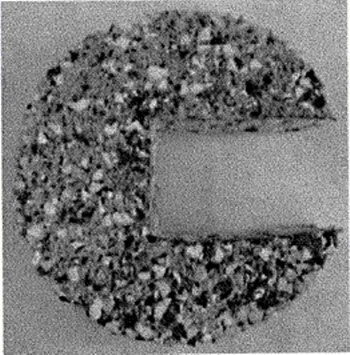

A piece prototype obtained with the new method.

• All the pieces obtained have constant and uniform properties.

• The time required in the process is considerably reduced. This time is till seven times reduced compared with a traditional oven.

• This method allows reusing a high percentage of plastic waste even though they were reticulated.

• The mould used to cold the product can be reused for a long period of time.

• All the components involved in the process are processed in an easy, fast and economic way. All the components are mixed in a first step and afterwards the mixture is heated by microwaves.

• The plastic components are used in powder or grain shape.

• Se obtienen productos homogéneos de elevado espesor (piezas entre 2,5 y 25 cm. de diámetro).

INNOVATIVE ASPECTS

• Homogeneity

• Thickness control

• Different shape and size

• The method is applicable to different plastic materials

This innovative process has been designed to use plastic wastes generated in different industries. EVA, polyethylene, polypropylene, polyurethane, foams, rubber or any combination of them can be used. Using the innovative method can be obtained pieces with different thickness depending on the application that this piece will have. For example:

• Road signs protectors.

• Net floats.

• Signalling buoys.

• Life preserver floats.

• Wheels for different vehicles.

• Soles for shoes.

• Ground sheets.

• Acoustic barrier sheets.

• Others.

• Specific area of activity of the partner: plastic industry

• Task to be performed: the research group is looking for companies interested in licensing this new method and put it in the market.

• Publication number: P2341424.

• Application date: 17/12/2008.

PCT: WO9000577ES.

Footwear and Textile

Construction and Architecture

Toys

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959