Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

EXCLUSIVE LICENSED

EXCLUSIVE LICENSED

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

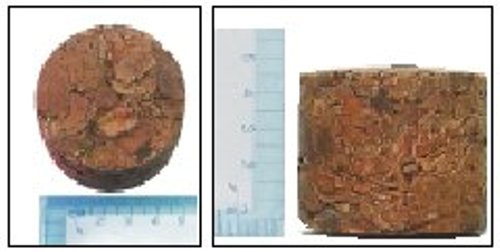

Briquettes of different densities and mechanical resistance can be obtained from almond shells without the addition of other substances. At 180 ºC with pressure of 640 kg/cm2, cylindrical briquettes, without grounding of the almond shells, have been obtained with very good mechanical resistance, whereas at 70-80 ºC with 640 kg/cm2 , briquettes with acceptable mechanical resistance are also obtained.

In the briquetting of lignocellulosic materials, such as sawdust, wood chip, newspaper wastes, etc., the material undergoes compression forces (between

150 and 1200 kg/cm2) with several compression machines: hydraulic, impact, extrusion. For most of the briquetting processes, with scientific information or patents, the process is carried out at room temperature and with moisture around 8-15 %.

Combustion briquettes are frequently formed by sawdust from wood or from bush, brushwood with different particle size distribution under 2 mm. Frequently, these material are contaminated or have smelly components in the combustion. These properties, fine particles and smelly components impede the use of these briquettes in domestic barbacues. Almond shells, with initial moisture around 8-12 %, is a material used as fuel in boilers and sometimes in domestic heating systems and barbacues. When almond shells is briquetted, transport, handling and market acceptance are facilitated. The presence of some small amount of aromatic plants, such as rosemary, vine shoot, etc, probably increase their acceptance. On the other hand, almond shell is a material that has another property that increases its acceptance, it is clean, so the final briquette is a clean product.

The same technology presented here can be used for other agricultural wastes, especially shells. In addition, other agricultural wastes, that are aromatic, can be used. Almond shell briquettes can be formed without addition of other substances, because they contain the natural components to obtain the solid

form. Almond shell briquettes can therefore be considered as an ecological material, with the same characteristics as the raw material. In addition,

briquettes from the initial almond shells, without previous grounding, can be obtained by the process explained in the following paragraphs. The briquettes,when burning, form hot coals with the same size as the almond shells.

The almond shell briquettes formed have density greater than 1000 kg/m3 and good mechanical resistance, depending on the operating conditions. When heating at 180 ºC under pressures of 640 kg/cm2 with a hydraulic press, briquettes with a cylindrical shape (diameter 5 cm; height 4 cm) are obtained. For these briquettes the breaking stress on the plane bases is 2500-3000 kg, whereas on the sides the breaking stress is 150-300 kg.

Briquetting of almond shells can be carried out by slight heating to 70-80 ºC, without previous drying of the shells, with compression stress of 640 kg/cm2.

In this case, the side breaking stress is also in the range of 150-300 kg. The mechanical resistance depends on the operating conditions and consequently

can increase with the compression stress.

The size of the briquettes obtained depends on the briquetting machine. There are machines on the market that have the same process as that used in the

laboratory hydraulic press. In these machines, the raw material is introduced in molds, where it undergoes the compression stress for a few seconds, and the briquettes are formed continuously.

The briquetting of some materials is not easy, due to the elastic properties of some materials, that after the mechanical compression, partially recuperate their initial form. Almond shell is a material, that cannot be compressed at room temperature, without the addition of other substances. Nevertheless, changing the conditions of moisture of the sample, temperature, pressure and time, the briquettes obtained have good mechanical properties, that remain for years.

Wood and Furniture

Materials and Nanotechnology

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959