Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The research group "Waste, Energy, Environment and Nanotechnology (REMAN)" of the University of Alicante has developed a procedure for the elimination of odours in recycled plastics by steam stripping.

This procedure comprises the following stages: (i) separation and conditioning of plastic; (ii) shredding of plastic; (iii) chemical washing with surfactant; (iv) rinsing of plastic material; (v) mechanical drying; and, (vi) deodorization of plastic. This last stage is done in a steam distillation column and is where the volatile organic compounds (VOCs) are extracted from the clean, dry material by steam distillation, and where the VOC-free plastic exits at the bottom of that column.

In this way, it is possible to improve the quality of recycled plastics and increase the reuse of plastics from both domestic and industrial waste as raw material for products for later use.

Companies interested in the commercial exploitation of this technology through licence agreements and/or technical cooperation are sought.

It is known that the demand for plastic containers is increasing and with it the volume of plastic in landfills. In addition, the reuse of household plastic waste is limited by its high content in food waste and cleaning products that are absorbed into the polymeric matrix, contaminating the material and being responsible for the unwanted smell of the polymer. These odorous substances are volatile organic compounds (VOCs) that cannot be removed by conventional washing.

Currently, conventional mechanical recycling consists of a selective classification of plastic waste based on the nature of the polymer, a water wash, to which reagents such as caustic soda, surfactants and oxidants can be added, and finally, mechanical drying is applied prior to the extrusion stage where the recycled pellets are obtained. There are several additives that can be added during the extrusion stage in order to encapsulate or extract the VOCs contained in the polymeric matrix, but these are not efficient enough in the removal of odours.

There is, therefore, a need to efficiently and environmentally friendly decontaminate these domestic plastic waste for subsequent use as a raw material in order to reduce their presence in landfills, to reduce operating costs in the recycling industry, as well as to increase the added value of the product.

The organic compounds that cause the bad smell of recycled plastics are found both inside the polymer matrix and on the surface of the plastic. In order to increase the quality of recycled plastics, the research group "Waste, Energy, Environment and Nanotechnology (REMAN)" of the University of Alicante has developed a procedure and a system to eliminate these odours by extracting volatile organic compounds (VOCs) with water vapour.

This solution is based on the fact that extraction with steam favours the internal diffusion of volatile compounds due to the working temperature, as well as decreases the boiling point of volatile organic compounds immiscible with water, increasing their evaporation from the polymer surface to the gas phase and consequent removal.

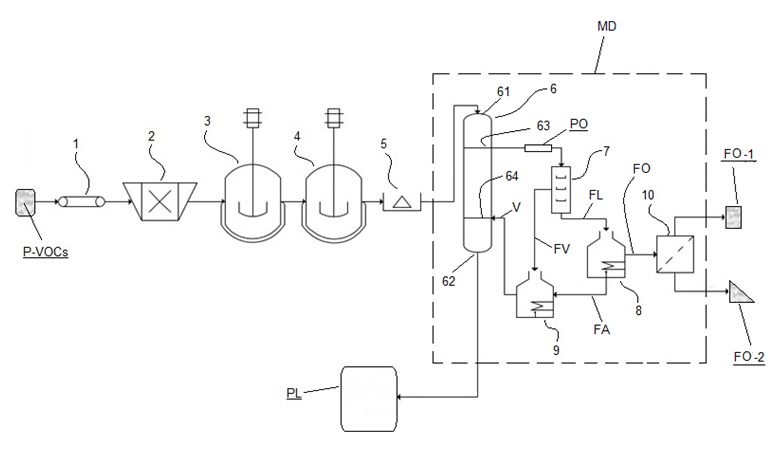

The procedure for the elimination of odours in recycled plastics comprises the following stages and equipment (Figure 1):

-

Separation of recycled plastic material (P-VOCs) by identification in an identification separation plant;

-

Shredding of the plastic in a shredder and reduction of the size of the plastic particles;

-

Chemical washing of shredded plastic with surfactant in a stirring tank;

-

Rinsing of the plastic material to remove dirt and chemicals used in chemical washing in a rinsing tank;

-

Drying of the rinsed material in a mechanical dryer;

-

Deodorising the dry plastic material in a deodorising module where:

- the plastic material is introduced at the top of a distillation column;

- the steam from a boiler enters through the lower side of the distillation column;

- the plastic material falls by gravity along the distillation column, the plastic material comes into contact with the steam and the organic components are extracted from the plastic material by steam stripping;

- there is an outlet of organic product, comprising water vapour and VOCs, at the top side of the distillation column; and

- the VOC-free plastic exits at the bottom of the distillation column.

Figure 1. Schematic diagram of the different elements of the procedure for carrying out odour removal in recycled plastic materials: 1. Separation; 2. Shredder; 3. Chemical washing; 4. Rinsing; 5. Drying; 6. Distillation column; 61. Upper part of column; 62. Lower part of column; 63. Upper side of column; 64. Lower side of column; 7. Droplet separator; 8. Isothermal tank; 9. Steam boiler; 10. Separator; P-VOCs: Plastic with VOCs; MD: Deodorizing module; V: Steam; PO: Organic product mixture; FL: Liquid fraction; FV: Vapour fraction; FO: Organic phase current; FA: Aqueous phase current; PL: Free plastic; FO-1: Organic compounds; and, FO-2: Water.

The steam stream that comes out from the top (after being in contact with the odorous plastic) contains a mixture of water vapour and organic compounds, i.e. it is a mixture of organic product (PO). This mixture is introduced into a droplet separator, from where the vapour fraction (FV) comes out on one side and the liquid fraction (FL) on the other.

The vapour fraction (FV) consists of water and is recirculated to the vapour boiler. Meanwhile, the liquid fraction (FL) is a condensed product that is composed of the organic phase along with the water dissolved in it. This condensed product is fed to an isothermal tank in which the organic phase (FO) is separated from the aqueous phase (FA) by decanting.

The aqueous phase current (FA) consists of condensed water which is fed back into the steam boiler, optimising the performance of the system. The organic phase (FO) contains organic compounds and water in solution. This stream is fed into a separator that separates the water (FO-2) from the rest of the organic compounds (FO-1).

Apart from obtaining a clean product that is a plastic free of VOCs and odours (PL) that is reusable for other uses, it ends up generating an organic product (PO) that is also reusable, where there is water (FO-2) that can be used externally for other uses, and can also be reused to be recirculated to the boiler; and where there are organic (FO-1) remains composed essentially of essential oils that can be commercialized or reused as fuel for producing steam.

Finally, the deodorisation stage can be carried out before or after extrusion:

- If the material introduced into the recycling process is the volatile fraction of plastic waste from bags and films, then the deodorisation stage would be more appropriate to apply after extrusion, for mechanical reasons.

- If the material is rigid, e.g. bottles, then the deodorisation process can be applied before or after the extrusion, as this material has a high density in both cases and does not volatilise causing material losses as may occur in the case of films.

This technology has the following advantages:

- The result is a clean product that is a plastic free of VOCs and odours with an increased quality in comparison with the recycled plastics obtained by conventional recycling.

- By increasing the quality of recycled plastic, new opportunities appear in the market for this type of plastic (e.g., packaging in the cosmetics and hygiene sector).

- Fully environment-friendly procedure.

- It boosts the reduction of plastics in landfills.

- It reduces the production costs in the industries of the sector compared to other technologies such as supercritical CO2 extraction.

- The deodorization module is a hermetically closed circuit that allows heat recovery.

- The deodorization module can act as an independent module of the recycling process. In this case, pellets recycled by other companies are fed into the system for removing malodours and improving the quality of the material.

- The organic phase obtained consists of essential oils (e.g., limonene or pinene) that can be marketed or reused as fuel for steam generation.

Given the existing background in this field of technology, there are no known processes that are based on the removal of odours by steam stripping. Therefore, the main innovative aspect of this invention is the removal of odours in recycled plastic by steam stripping.

By means of this process that removes the odours in plastics originating from domestic and industrial sources, it is possible to solve the issues of conventional washing and increase the application of these plastics as raw materials in the polymers industry.

The system has been developed on a laboratory/pilot scale and can treat approximately 0.5 kg/h of plastic, depending on its origin.

The present invention manages to remove contaminants, and with them, volatile organic compounds (VOCs) that produce bad smell in recycled plastics. This process extracts the VOCs by steam stripping. This invention is applied to plastics of varied nature, such as polyethylene, polypropylene, polyester, etc. from plastic waste, whether of industrial or domestic origin.

Therefore, this procedure could be useful in the plastic recycling sector or manufacturers of plastic containers as an initial stage to ensure the quality of the raw material.

-

Patent licensing agreements.

-

Technical cooperation agreements (R&D projects) for the use of the technology or application in other waste or sectors.

-

Subcontracting agreements for technical assistance, training, etc.

Profiles of companies sought:

-

Recycling of plastic waste.

-

Manufacturers of plastic containers.

-

Producers of virgin raw material.

This technology is protected by patent application.

- Title of the patent: "Removal of odours in recycled plastic by steam stripping".

- Application number: P201930501.

- Application date: 04 June 2019.

Chemical Technology

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959