Can we help you?

Contact us

Can we help you?

Contact us

Thank you for contacting us

Your form has been submitted successfully Our team will contact you again as soon as possible.

Whooppss...!! An error has occurred

Try sending later or write an email directly to areaempresas@ua.es

PATENTED TECHNOLOGY

PATENTED TECHNOLOGY

INFO

SHEET

DOWNLOAD

EXECUTIVE

ABSTRACT

CONTACT DETAILS: Research Results Transfer Office-OTRI

University of Alicante

Tel.: +34 96 590 99 59

Email: areaempresas@ua.es

http://innoua.ua.es

The University of Alicante jointly with the Queen’s University at Belfast has developed a process to pigment coating plastic articles by mean of spring polymer and pigment powder. The process is tested at laboratory scale and is based on the melting “in situ” of polymer powder in combination with the pigment onto the surface of the part already formed. The technology overcomes traditional problems when coating plastic articles and is very appropriated to polyethylene painting. Partners for acquiring the patent rights are sought.

Normal practice when colouring or protecting a plastic material is to introduce the pigment when forming the plastic such that the pigment particles lodge themselves interstitially between the polymer molecules giving the plastic material the colour of the pigment throughout.

This has the obvious disadvantages that an extra step has to be introduced during the production of the plastic, only one colour can be applied, and the process is irreversible. A large amount of pigment is also required to colour the whole plastic as the pigment is included during its make-up rather than simply coated on its surface. Furthermore, the pigment added during the manufacture of the plastic will alter its physical properties such as strength, which may be undesirable.

The developed technology is directed towards overcoming these problems and in particular to providing a cheaper and more versatile process for coating various surfaces including plastic materials.

INNOVATIVE ASPECTS

- The developed technology overcomes traditional problems when coating plastic articles: extra steps in plastic production, multicolouring, irreversibility, pigment amount, cost, etc.

- The quality of the finishing can be significantly improved since the glossy of this painting can better than that obtained in the conventional process.

- It can be applied to polyethylene painting, a very spread out material.

MAIN ADVANTAGES

- Some of the benefits of the system include:

- The pigment consumption is remarkably reduced since the part is pigmented only on the surface.

- The properties of the polymer constituting the body of the part are unaltered.

- The parts can be decorated in different colours in a very simple way.

- The compatibility of the painting with the polymer is complete, since the painting is mainly the same polymer.

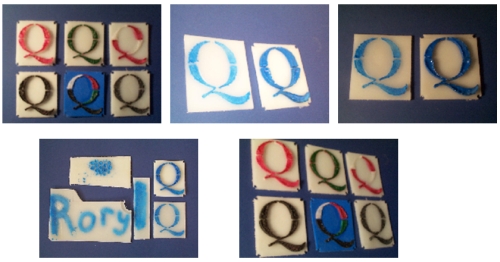

Some examples can be seen in following pictures:

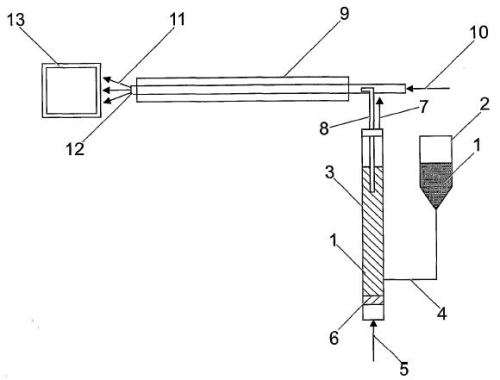

A prototype machine can be seen in next picture:

This process can be used to paint any suitable surface to provide a temporary or permanent coating. Such surfaces include plastic, metal, glass, ceramic, etc. Many suitable polymers are useable such as polyethylene, polypropylene, nylon, foamed EVA, etc.

One application is to coat metal such as the inside of a metal shell or mould, pre-moulding, to provide a coating attachable to the moulding material, e. g. as a colour scheme, to thicken an area of the moulding or to add any protective-like coating.

In coating plastics, the plastic material could be a thermoplastic material. Preferably, the powdered plastic of the paint precursor is the same polymer as the plastic material to be coated. Optionally, the powdered plastic of the paint precursor is a polymer which is compatible with the plastic material to be coated.

In some applications, the coating is useable as an adhesive between the surface to which it is applied, and a second surface, e. g. two plastic parts or plates. Sometimes, the paint precursor includes one or more additives or filler materials such as a UV-adsorber, microwave, etc., glass microspheres, antibacterial agent, etc. Such substances are known in the art, and enhance the properties of the coating.

The University of Alicante is looking for partners interested in:

· Developing the technology for commercial use

· Establishing patent license agreements to acquire the rights to use or commercialising the technology

British Patent Application No. 0011284.7

The Queen's University of Belfast & The University of Alicante, Spain

Catch: Spray Pigmentation

IP Title: Coating Process

Our main research fields are:

- Pyrolysis, Gasification and Incineration

- Environmental Water Management

- Environmental Managemente of Industrial Waste

- Synthesis and Optimization of Chemical Processes

- Rectification and Extraction of Multicomponent Mixtures

- Activated Carbon

- Balance between Solid-Liquid-Liquid-Solid Phases

- Holographic Interferometry

- Polymer Processing

- Food Technology

- Time of Stay Distribution in Electrochemical Reactors

- PCDD/PCDF Detection and Analysis

Toys

Wood and Furniture

Materials and Nanotechnology

Chemical Technology

Transport and Automotive

Carretera San Vicente del Raspeig s/n - 03690 San Vicente del Raspeig - Alicante

Tel.: (+34) 965 90 9959